Journal of Pharmaceutics & Pharmacology

Download PDF

Research Article

Innovative Approaches to Enhance Dissolution Rate of a Hydrophobic Drug Glimepiride

Ismail Shehada MB1, Usman S1*, Akram M2 and Usman A3

1Department of Pharmaceutics, RAK College of Pharmaceutical Sciences, UAE

2Department of Pharmaceutics, University of Karachi, Pakistan

3Sindh Medical University, Pakistan

*Address for Correspondence: Usman S, Department of Pharmaceutics, College of Pharmaceutical Sciences, RAKMHSU, Ras Al Khaimah, UAE, Postal code: 11172, Cell: +971 558902559, Fax: +971 72269997; E-mail: shahnaz.usman@rakmhsu.ac.ae; shahnazgauhar@gmail.com

Submission: 29 August 2020;

Accepted: 15 October 2020;

Published: 28 October 2020

Copyright: © 2020 Ismail Shehada MB. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

section

Objective: In the present study an effort was made to design and

develop an immediate release tablet of glimepiride (as a model drug)

by using the combination of two approaches i.e. conventional and

innovative to enhance the dissolution rate of hydrophobic drugs.

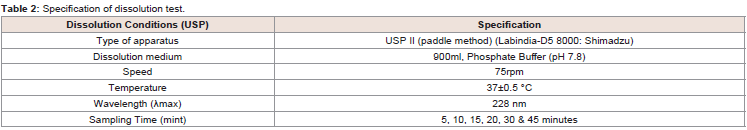

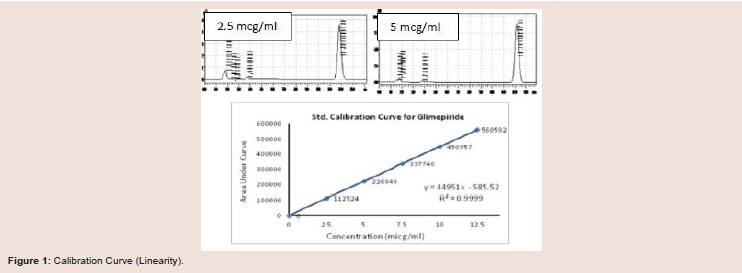

Method: In the proposed study, USP analytical method was validated

for the determination of glimepiride in its formulations. The calibration

curve was linear over the concentration range of 2.5-12.5 µg/ml with a

regression analysis (r² = 0.9999). For getting an idea about the release of

drug from its dosage form, innovator brands were picked and estimated

for pharmaceutical parameters. On the basis of this information, 10

experimental batches of tablets were prepared. The optimized batch

was prepared by using 2:1 ratios of tween 80 and PVP K30 by slurry

technique. Pre-compression and post-compression parameters were

evaluated to confirm the validity of the design and development of

processes. The optimized batch was subjected to stability studies for 03

months at 40±2 °C & % RH: 75±5%.

Results: The selected excipients and their proportions were found

compatible with drug as well as with each other. The enhancement of

dissolution indicated that the combination of Tween 80 and PVP K-30

in the slurry method made the faster release of the drug possible. The

release rate of drug from optimized batch was estimated by a validated

HPLC analytical method and compared with innovator results.

Conclusion: It was concluded that the proposed slurry technique

is a simple and easy to adopt method and could be useful for the

improvement of drug release from the tablets. The results indicated

that the releases of drug from formulated tablets were same as that

of innovator.

Keywords

Hydrophobic drug; Method to improve solubility;

Formulation of tablets; Glimepiride; HPLC method validation;

Innovative approaches

Introduction

Solubility is the major limiting factor for the absorption of

hydrophobic drugs. In this regard the drug needs to be solubilized

first in the solution to be available for absorption site. Drug release

and dissolution are considered as the rate limiting steps in order

for the drug to be absorbed from the Gastrointestinal Tract (GIT).

Glimepiride is the drug which has low solubility and high permeability

and falls in class II drug. In such classes the only limitation is how to

permit the partitioning of the drug across epithelial cell membrane.

Because the drugs have a high permeability, the absorption will be

very fast once the drug is solubilized.

Glimepiride is useful in the treatment of non-insulin dependent

diabetes mellitus (NIDDM) [1,2]. It is 1-(p-(2-(3-ethyle-4-methyl-

2-oxo-3- pyrroline-1-carboxamido) ethyl) phenyl) sulfonyl)-3-

(trans-4-methylcyclohexyl) urea which belongs to third generation of

hypoglycemic sulfonylurea. Literature reviews reveal that glimepiride

shows more potential benefits such as lower dose, rapid onset of

action, longer duration of action and lower insulin C-peptide level, as

compared to other available sulfonylureas [3,4].

The main challenge in formulating the drug dosage form is

to increase the dissolution rate of drug with a simple, safe, and

cost-effective formulation design. A number of techniques are

available in the literature to overcome dissolution problem such as

Inclusion complexes [5], Solid dispersions [6], Co-solvent [7], Selfnanoemulsifying system [8], Nanocrystal [9], Micelles Formation

[10], and Hydrotropic but at the same time it is difficult to adopt such

techniques in routine process because of their complexity [11,12].

In the present investigation, efforts were made to improve the

dissolution of glimepiride tablets by using the combination of two

approaches i.e. conventional and innovative, as it is a bioavailability

controlling step. Tablets were prepared by using the wet granulation

for making granules but before that the slurry of API and surfactant

was prepared. In literatures, different approaches are reported but

no such technique is described on the preparation and evaluation

of glimepiride. Therefore, it is totally a new and easy approach to

improve release of drug from its dosage form.

The primary aim of the present study is to enhance and improve

the dissolution rate of hydrophobic drug (Glimepiride as model

drug) by employing an innovative technique of making slurry of

polysorbate 80 and PVP K-30 with API. Pre-compression and postcompression parameters were evaluated to confirm the validity of

the design and development of processes. To evaluate the dissolution

profile and efficacy of newly formulated tablets of glimepiride, the

formulations were compared with innovator brand tablets. The

study was also focused on the accuracy of the formulation and it was

estimated by accelerated stability studies of the tablets.

Materials and Methods

Materials:

Glimepiride reference powder (purity 99.61%) was obtained as a

gift sample from Julphar, Ras Al Khaimah, UAE. Lactose monohydrate (VWR International, Germany), Microcrystalline cellulose (Fluka

- Biochemika, Germany), Polyvinyl Pyrrolidone K-30 (PanReac -

AppliChem, Italy), Cross Povidone (Basf Chemicals; Gift sample from

Julphar), Tween 80 (Carl Roth, Germany), Sodium Starch Glycolate

(Gift sample from Julphar), Mg stearate (Sigma Aldrich, Germany)

and all other chemicals and solvents such as methanol, acetonitrile &

Phosphate Buffer, used were of analytical reagent grade.Estimation of glimepiride:

In order to achieve the consistent, reliable and accurate data for

the quality analysis of API alone and in its dosage form, analytical

method play a key role. In the present study, the USP reported HPLC

analytical method was first validated as per ICH (International

Conference Harmonization) guideline [13] in accordance with

facilities and feasibility of equipment and then used to estimate

glimepiride as raw material as well as in newly formulated tablets

(USP-37) [14].Mobile phase preparation:

Accurately weighed 0.5 g of monobasic sodium phosphate was

taken and dissolved in 500ml of double distill water. The solution

was mixed thoroughly, and the pH was adjusted to 2.4 with 10 %

phosphoric acid. Acetonitrile with phosphate buffer was added in the

ratio of 1:1, mixed and filtered through 0.45 µm millipore filter paper.Preparation of diluent: Acetonitrile and water in a ratio of 9:1:

Preparation of Standard stock solution: Accurately weighed

10mg of glimepiride reference powder was taken and diluted with 100

ml of diluent and sonicated for 5 minutes. The final concentration of

the standard stock solution was 0.1 mg/ml (100 µg/ml).Construction of calibration curve for the estimation of Glimepiride:

A series of dilution were prepared in the diluent mixture according

to the study design. From the stock solution, 0.25, 0.5, 0.75, 1.00, and

1.25 ml were pipetted out into a 10 ml volumetric flask separately and

was made up to 10ml with the diluent. The concentration of these

solutions was 2.5, 5, 7.5, 10, and 12.5 μg/ml respectively. Absorbance

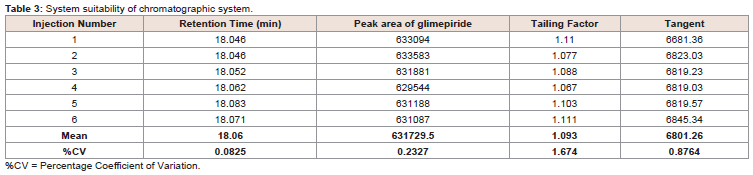

of the solutions were measured at λ = 228 nm.System suitability test was carried out by six (6) replicates of

sample solution (10 µg/ml) to check the repeatability, peaks symmetry,

theoretical plates of the column, retention time and reproducibility of

the chromatographic system.

Linearity of the method was evaluated in the range of 2.5-12.5

μg/ml. Limit of Detection (LOD) and Limit of Quantification (LOQ)

was estimated by ICH guideline [15]. It gave the idea that the lowest

concentration of analyte in a sample was determined with acceptable

precision and accuracy.

Selection of excipients and their evaluation:

For the design and development of any new formulation it is

important to work on the intrinsic properties of API and the excipient.

In present study, pre-formulation studies for different excipients were

carried out to investigate the influence of their inherent properties

on the pharmaceutical construction. The data obtained from studies

provided the information regarding the interpretation of interactions

among the excipients as well as with API.Drug-excipient compatibility studies using FTIR:

FTIR spectroscopy (Agilent Technologies, Cary 630 FTIR) was

performed for the pure active drug and each excipient separately

and also for the blended mixture of drug and excipients. This study

was done to identify the presences of characteristics peaks for each

functional group in the compounds for each ingredient separately as

well as for interactions in the blended mixture of powders.Differential Scanning Calorimetry (DSC) studies:

Glimepiride and the excipient mixture, after preparing the

granules by wet granulation and slurry method, were subjected

to differential scanning calorimetric analysis to know about any

interaction between the drug and excipients. The calorimeter (ModelShimadzu -DSC 60+) was operated at a scanning rate of 10 °C per

minute and heated between 25 to 400 °C.Particle size and size distribution:

The particles size and shapes affect the dissolution rate of the drug

and their bioavailability. The study was done to calculate the Mean

Particle Size (MPS) and Polydispersity Index (PDI) by using Malvern

Zeta sizer Nano ZS (Malvern Instruments). The samples were

measured for MPS and PDI at a fixed angle of 90° at a temperature of

25 °C and average zeta potential (mV) was measured at 25 °C.Scanning electron microscopy:

The shape and surface feature of the glimepiride blended mixtures

were investigated by employing SEM (Hitachi, Model SU 1510) and

was observed under reduced pressure employing an acceleration

voltage of 15 kV.X-ray Diffraction:

patterns of drug blends were performed to confirm the nature

(crystalline or amorphous) of drug. Diffractograms were captured

using a step width of 2θ between 2° and 40° at a rate of 2° min-1 at

ambient temperature.Experimental design:

The objective of the study was to maximize the release rate of drug

from tablets by using some innovative approaches. In the present

study, slurry method was used to improve the dissolution rate of the

glimepiride which was taken as a model drug.The preliminary information regarding the characteristics of

excipients and their proportion and range was obtained from USP

and BP [16]. The tablet of glimepiride was initially prepared by using

wet granulation method. The trial batch of tablet was prepared as per

innovator, Amaryl, 2 mg (Glim-A) tablet and dissolution test was

performed according to USP.

Preparation of tablets by wet granulation:

All the ingredients such as glimepiride, PVP K -30, Lactose

monohydrate, microcrystalline cellulose and sodium starch glycolate

were weighed carefully and dry mixed to get homogenous mixture of

powder. The powder was granulated with water and passed through

mesh # 40. The wet mass was dried at 35 °C and was passed again

through mesh # 30. The remaining amount of sodium starch glycolate

and Mg stearate were added and were compressed on 9.25 mm Oblong shape plain punches at a theoretical weight of 170 mg±7.5%.Preparation of tablets by innovative approach (Slurry method):

Calculated amount of purified water was taken and polysorbate

80 and PVP K-30 were added and mixed to dissolve. Glimepiride

was added into the same solution and mixed again with the help of

homogenizer (IKA; MODEL: T 25 D, Germany) to produce uniform

slurry. Lactose monohydrate, microcrystalline cellulose pH 102 and

half amount of sodium starch glycollate were added and mixed well.

The mixture of powder was granulated with slurry till homogenous

wet mass was produced then passed through sieve # 40 mesh, dried

at 45 °C and the remaining amount of sodium starch glycolate

and magnesium stearate was added. Finally, the blended powder

was compressed by Compression machine (Single Punch, D Type

Tooling; Dwell time 0.75 second; Faisalabad) on 9.25 mm oblong

shape plain punches at a theoretical weight of 170 mg±7.5%.Formulation optimization:

Initially the prototype formulation was prepared by using the

same ingredients as that of Glim-A. The dissolution rate of the tablets

was calculated and based on the results; the series of formulations

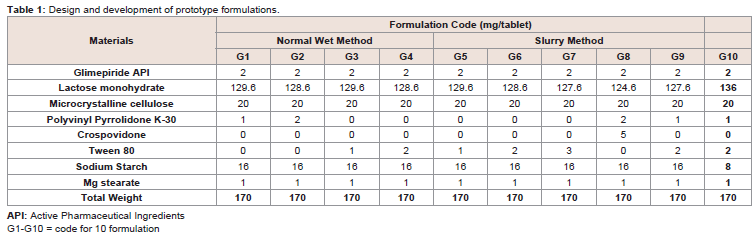

were designed with same ingredients as mentioned in (Table 1). In

the proposed study, the higher and lower concentration of polyvinyl

pyrrolidone K-30, Polysorbate 80 and crospovidone were used

separately and in combinations in order to optimize the release

pattern of drug from formulationAfter the satisfactory results of Batch # G-9 (Table 1), where the

dissolution was almost 90% in 15 minutes, the prototype formulation

G-9 with Polysorbate 80 and PVP K-30 was selected for further

optimization. In order to improve the formulation, the changes were

made in the composition of sodium starch glycolate and lactose.

Finally, the following compositions were selected for the optimized

Batch (G-10) with dissolution rate of more than 90% in 15 minutes

(Table 1).

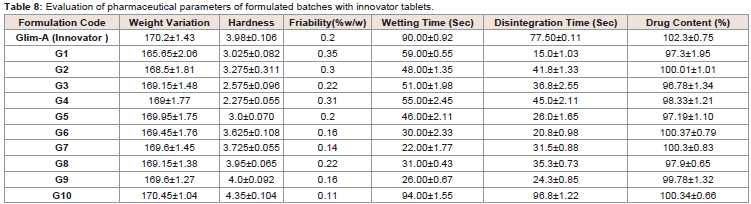

Quality evaluation of formulated tablets:

The innovator brand tablets and formulated tablets were subjected

to recommended pharmacopeial tests for their quality attributes.Weight variation:

It is one of the most important parameters related to the weight

uniformity and is supposed to indicate the content uniformity of

each tablet. If there is any variation in the weight, it means there is

variation in amount of API in tablet.Hardness and thickness:

The ability of a tablet to withstand at specific pressure before

breaking influences the disintegration and friability of tablets.

Similarly, the thickness and diameter/length have a great impact on

the packaging behavior of tablets dosage form.Friability test:

Friability test of tablets is one of the imperative parameters that

assess the handling of drugs during transportation from manufacturer

to distributer and then their delivery to the patients. Friability for all

formulated tablets were performed by using the procedure defined in USP and BP [17,18].Wetting time:

The wetting test measures the ability of a tablet to allow liquid to

wet and penetrate between the compact particles of powder which

deals with the disintegration aptitude of tablets. In the present study

0.1% (w/v) Methyl blue solution was used. The tablet was carefully

kept on the surface of the dye solution until it’s wetted completely, the

time was recorded [19,20].Disintegration test:

The mechanical breaks of tablet into small granulated particles

help to calculate the disintegration time of a tablet. This parameter

provides an in-vitro simulation for drug disintegration and dispersion

after intake and gives an idea about how it will perform in the

dissolution test. All the tablets were evaluated for their disintegration

time as per USP [21].Drug content assay of Glimepiride tablet:

The content assay of all the tablets were carried out by using the

validated HPLC method for quantitative analysis of drug.In vitro drug release studies:

It is an important process that provides the in-vitro simulation

for bioavailability studies. Especially in dosage form design and

development, it works as a fundamental quality control parameter for

the evaluation and assessment of drug release from their solid dosage

forms.Standard preparation:

Accurately weighed 10mg of glimepiride reference standard

powder was taken and carefully diluted with 100ml of diluent (9:1)

and sonicated for 5 minutes. 1.5 ml of this solution was diluted with

50ml of dissolution medium. The final concentration was 3 µg/ml.Sample preparation:

One tablet was introduced into each of six individual vessels

containing 900 ml of phosphate buffer (pH 7.8). 5ml from each vessel

was withdrawn after time intervals of 5, 10, 15, 20, 30 & 45 minutes

and filtered before injecting into HPLC. The samples were analyzed

at λmax = 228 nm.Stability studies:

After the pharmaceutical evaluation of all formulated batches the

optimized batch (G-10) was kept for stability for three months (0,

1, 2 & 3 months) under accelerated conditions i.e 40±2 °C; 75 ± 5%

R.H, as per ICH guidelines and retained under the three condition

of packaging [22,23]: 1) Alu/Alu blistering 2) Amber container 3)

without container.Stress testing of optimized batch:

The stress testing was performed on prepared tablets (G-10)

under the 4 different conditions for 24-hours i.e acidic (0.1N HCl),

alkaline (0.1N NaOH) & Ultraviolet degradation and Hydrogen

peroxides (6%).Results and Discussions

In 2015, Kline & Co-workers conducted a market survey and

they found that the large number of drugs belonged to BCS class

II (poor solubility, high permeability) [24]. The drugs of this class

had poor bioavailability due to their limited solubility. Thus, they

required improvement in solubility to enhance the effectiveness of

the compounds. The pharmaceutical researchers are continuously

working to overcome this problem and try to develop a set of

bioavailability enhancement methods and technologies. Few of these

methods give a better understanding, whereas some others require a

specialized expertise and manufacturing capabilities.

In the present study we have made an attempt to develop a simple

and easy method to improve the dissolution rate of a formulated

glimepiride tablet. Moreover, it was made sure that the hardness of

the tablets is pertained to appropriate limit in order to control the

shipping and handling.

Analytical methods validation for the estimation of Glimepiride [25]:

In the present study the analytical method used for the

determination of glimepiride was taken from USP-38 [26]. The

reason for opting this method was to make sure that the release of

drug from newly formulated tablets must be same as that of innovator

tablets, as the USP method is actually established by the innovator.

Before the estimation of glimepiride, it is necessary to validate the

method as per the feasibility to make sure that the estimation is

accurate and reproducible. The main objective of method validation

is to demonstrate the reliability of a particular equipment and

analytical method for the quantitative determination of an analyte(s)

concentration in a specific sample.Construction of calibration curve:

The calibration curve of glimepiride was linear in the concentration range of 2.5 to 12.5 μg/ml, with a regression analysis (R2) of 0.9999, 0.9998 and 0.9995 with different time intervals (Figure 1). The curve

was plotted by area under the curve vs concentration of glimepiride at λ = 228 nm. Six consecutive injections of 10 µg/ml were used to verify the resolution and reproducibility of the chromatographic

system (System suitability) as recommended by the ICH guideline for

analytical method validation [15] (Table 2 and 3).The % CVs of the retention times and peak areas of glimepiride

for the six injections was 0.0825 and 0.2327 respectively. The Mean

theoretical plate count, based on USP tangent calculations, was

6801.26 (Table 3). The Limit of Detection (LOD) and Limit of

Quantitation (LOQ) were estimated as 0.0625 µg/ml and 0.125 µg/ml

respectively (Table 3).

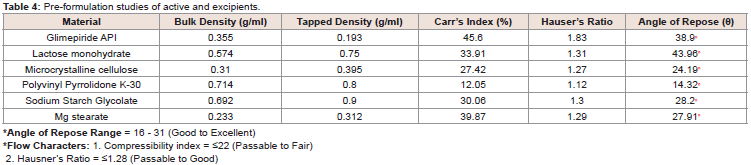

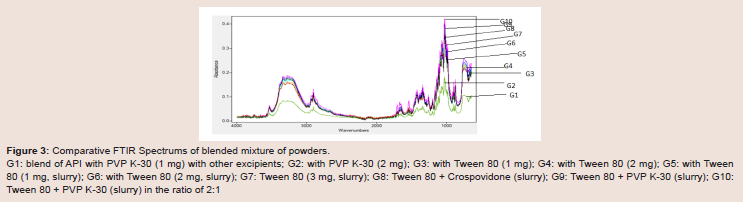

Pre-formulation studies:

Before the development of any dosage form, it is necessary to

determine the physical and chemical properties of drug powder. This

type of information might be needed as the formulation progresses.

In pre-formulation studies the physiochemical properties of the

pure drug alone and with the excipients were investigated (Table 4 and 5). The main reason to conduct pre-formulation studies is to

determine the core characteristics of excipients which will be used in

the formulation and development of an enhanced dissolution rate of

glimepiride tablet.The studies quantified that glimepiride had a very poor

compressibility and very bad flow properties which were mainly

due to its hygroscopic nature (Table 4). Other excipients also had

variation in their flow properties and for this reason different

techniques are used to prepare granules for tablets compression. In

the present study, tablets were prepared by wet granulation as well as

an innovative technique (slurry method) was introduced for tablets

erection to improve drug release rate from dosage form (Table 1).

After the study of flow properties (Table 5), it was observed

that the bulk and tapped densities for blended powders varied from

0.43-0.50 g/ml and 0.51-0.63 g/ml respectively. Carr’s index values

were in the range of 13.79 to 22.22%, which indicated that, the use of

different ratios of PVP K-30, crospovidone and Tween 80 have made

their effect on the flow of the powder blends. The angle of repose for

excipients were 14.32° - 43.96° which indicated the two extreme ends

whereas the ten (10) formulations were found in the range of 16.50 to

31.93, which indicated an excellent to good blend flow property (aid

not needed) according to the USP [27] (Table 4 and 5).

The values also indicated that when changes were made in ingredient such as in place of polyvinyl pyrrolidone K-30, Tween 80

was used, the angle of repose also changed from 27.38 (G2) to 30.84

(G4) (Table 5). Similarly, when the polyvinyl pyrrolidone K-30 and

crospovidone were used in combination with Tween 80, angle of

repose of G8, G9 and G10 were moved from good to excellent range

(Table 5).

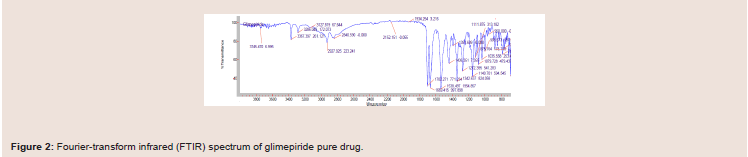

Figure 3: Comparative FTIR Spectrums of blended mixture of powders.

G1: blend of API with PVP K-30 (1 mg) with other excipients; G2: with PVP K-30 (2 mg); G3: with Tween 80 (1 mg); G4: with Tween 80 (2 mg); G5: with Tween

80 (1 mg, slurry); G6: with Tween 80 (2 mg, slurry); G7: Tween 80 (3 mg, slurry); G8: Tween 80 + Crospovidone (slurry); G9: Tween 80 + PVP K-30 (slurry); G10:

Tween 80 + PVP K-30 (slurry) in the ratio of 2:1

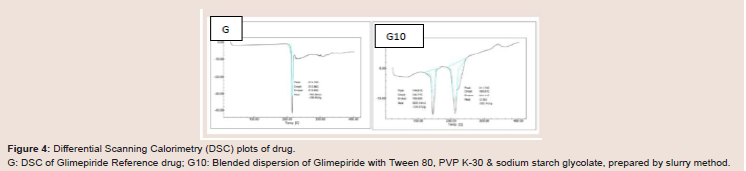

Figure 4: Differential Scanning Calorimetry (DSC) plots of drug.

G: DSC of Glimepiride Reference drug; G10: Blended dispersion of Glimepiride with Tween 80, PVP K-30 & sodium starch glycolate, prepared by slurry method.

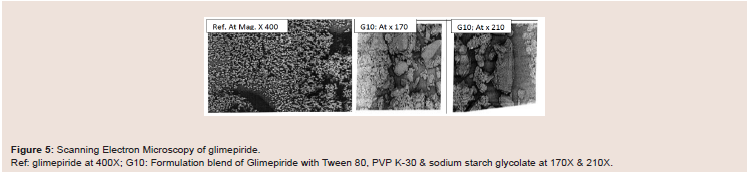

Figure 5: Scanning Electron Microscopy of glimepiride.

Ref: glimepiride at 400X; G10: Formulation blend of Glimepiride with Tween 80, PVP K-30 & sodium starch glycolate at 170X & 210X.

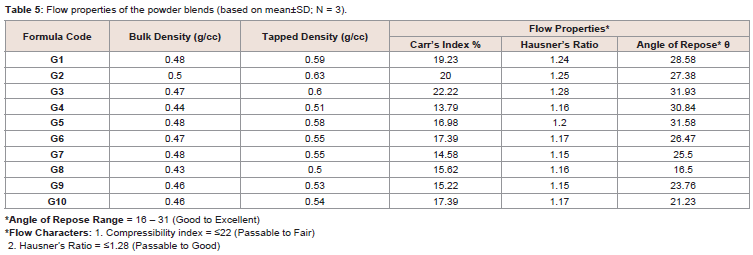

Drug-Excipient Compatibility Studies using FTIR:

Sometimes interactions can happen between the pure active

drug and the additive excipients. In order to estimate the level of this interaction, FTIR studies were performed for the active drug,

excipients and for blended powder mixtures of 10 batches respectively

(Figure 2 and 3). Figure 2, glimepiride pure active drug shows the bond

vibrations at 3367 cm-1 (N-H stretch), 1707 cm-1 (C=O) and 1346 cm-1

(S=O). After mixing the pure active drug with other excipients, there

were no major shifting in the peaks and all the functional groups

were clearly observed (Figure 3). From this data it was concluded that

there were no interactions between the glimepiride functional peaks

and the excipients in the formulations mixtures, indicating that all of

the ingredients used in the formulations were compatible chemically with each other (Figure 3).Differential Scanning Calorimetry (DSC) studies:

In order to confirm the physical state, DSC was also performed

to analyze the different samples. The glimepiride coarse powder

exhibited a single endothermic peak with a single melting point

[28]. Thermal analysis was conducted on blended dispersion of G2,

G4, G6, G8, G9 & G10 of glimepiride. The second peak appeared

but it was separated from drug peak. This indicated that there was

no interaction between drug and excipients, but the dissolution

enhancement occurred due to solubilization of drug by Tween 80, not

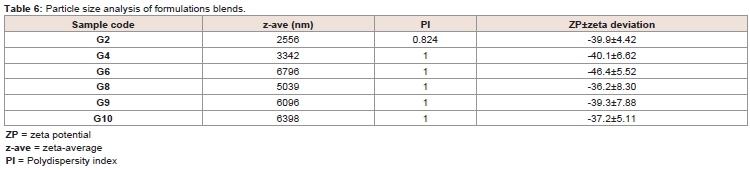

due to the change in structure or amorphous formation (Figure 4).Particle size analysis of glimepiride blended powders:

The z-ave and PI of the reconstituted suspensions were analyzed

to determine particle size and their distribution. The results indicated

that the z-ave of formulations blend increased when mixed with

Tween 80 (G4), when made blend with slurry method (G6), PVP

K-30 with crospovidone (G8), PVP K-30 with Tween 80 (G9) and

G10 with reduce amount of sodium starch glycolate. On the other

hand, there were no changes in PI that indicated that all the particles

were almost under the same population and were mono dispersed.

Therefore, a negative charge on ZP indicated that any of excipient of

the formulation blends having -ve charge also had the surface charged

with -ve. (Table 6).The addition of stabilizers, binder or suspending agents in

formulation can affect the morphology of particle in suspensions,

which was already confirmed by other authors [29]. In order to

characterize the morphology of glimepiride particles, SEM imaging

was performed, and the micrograph of the particles showed that

particles were irregular in shape and size (Figure 5).

X-ray diffraction studies were conducted to confirm the

physicochemical characteristics of blended mixture of formulations.

Diffractograms exhibited sharp peaks of diffraction at an angle of 2θ

value of 12.656°, 16.540°, and 20.120°, with very ignorable variation between different blends of powder, which indicated the presence of

crystalline structure.

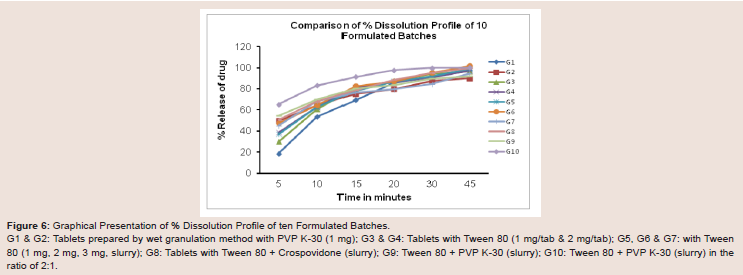

Figure 6: Graphical Presentation of % Dissolution Profile of ten Formulated Batches.

G1 & G2: Tablets prepared by wet granulation method with PVP K-30 (1 mg); G3 & G4: Tablets with Tween 80 (1 mg/tab & 2 mg/tab); G5, G6 & G7: with Tween

80 (1 mg, 2 mg, 3 mg, slurry); G8: Tablets with Tween 80 + Crospovidone (slurry); G9: Tween 80 + PVP K-30 (slurry); G10: Tween 80 + PVP K-30 (slurry) in the

ratio of 2:1.

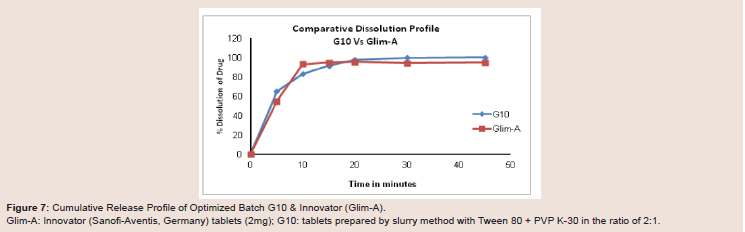

Figure 7: Cumulative Release Profile of Optimized Batch G10 & Innovator (Glim-A).

Glim-A: Innovator (Sanofi-Aventis, Germany) tablets (2mg); G10: tablets prepared by slurry method with Tween 80 + PVP K-30 in the ratio of 2:1.

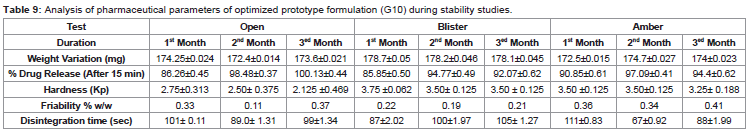

Table 9: Analysis of pharmaceutical parameters of optimized prototype formulation (G10) during stability studies.

Development & optimization of glimepiride tablets:

After analyzing the pre-formulation parameters of glimepiride

powder mixture, immediate releasing tablets were prepared. The

main goal of this study was to improve the dissolution of poorly

soluble drugs (glimepiride), 10 different batches were designed by

using different excipients like PVP K-30, Crospovidone and Tween

80 with different concentrations (Table 1). The basic concept of

excipients selection was based on actual components of innovator

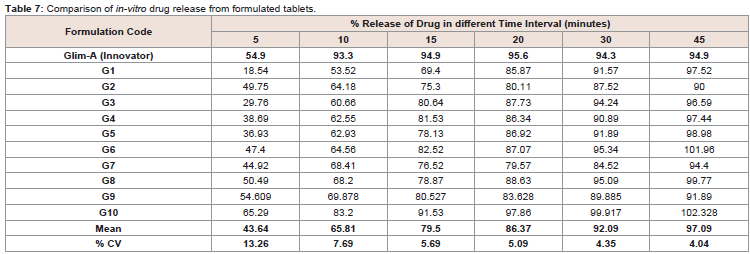

tablets (Glim-A; 2 mg).First two batches of tablets (G1 & G2) were prepared by wet

granulation method by using Glim-A information followed by

dissolution. The results of these tablets were not satisfactory (69.40%

and 75.30% in 15 min) in comparison to innovator product (94.9%

in 15 min). G3 & G4 were constructed with Tween 80 by using 1 mg/

tab and 2 mg/tab instead of PVP K-30 (Table 1). The assortment of

Tween 80 was due to its well-known functions as wetting agent, the main reason for its selection was that Tween is a nonionic surfactant

and has remarkable properties as emulsifier. Therefore it is considered

for not only improving the wetting of the drug but also enhances the

solubility. But the results obtained were not as per the desired target

(Table 7 and Figure 6).

The innovative technique slurry method were used to design G5,

G6 & G7 by using 1, 2 & 3 mg/tab Tween 80 separately (Table 1).

Dissolution test were performed and it was found 78.13%, 82.52% &

76.52% respectively. (Table 7 and Figure 6).

All the above mentioned design of formulations indicated that

the Tween 80 (2 mg/tab) gave the best release of drug as compared to

others. So, the formulation containing 2 mg/tab amount of Tween 80

was selected as model for further modification in the formulations.

The first amendment was made with Crospovidone and Tween (G8)

(Table 1). Tablets were prepared by slurry method. The Crospovidone

works as super disintegrants so it was supposed that the dissolution

would significantly increase. But practically there were no notable

change i.e. 78.87% drug released in 15 minutes (Table 7). G9 was

designed with PVP K-30 & Tween 80 (Table 1). The wet mass of

granules was prepared by slurry method with calculated amount of

water (34 µl/tab). The granules were compressed on 9.25 mm oblong

shape plain punches at a theoretical weight of 170 mg±7.5%. The

quality control parameters were analyzed to calculate the release of

drug. It was found 80.53% in 15 min (Table 7).

Prototype optimized batch (G10) was prepared by using the same

concentration of Tween 80 and PVP K-30 as that of G9 with the

reduction in the amount of sodium starch glycolate i.e. from 16 mg/

tab to 8 mg/tab and addition in the amount of lactose monohydrate

that was 136 mg/tab (Table 1). The tablets were prepared by the same

slurry method with slight increase in the quantity of water (54.4 µl/

tab).The dissolution test revealed marked increase in release of the

drug i.e. 91.53 % in 15 minutes (Table 7). G10 was taken as the Check

Point Batch (CPB). For further verification and conformation of drug

release from the tablets, comparatively a larger batch was prepared.

The data was collected and compared with innovator tablets for the

release of drug repetitively (Figure 7).

Pharmaceutical evaluation of formulated tablets:

The pharmaceutical evaluation of tablets was carried out to keep

the check on the quality, consistency, uniformity and efficacy of

the tablets in the same batch of formulation as well as between the

batches (Table 8). After quality analysis the tablets (G10) was kept for

stability studies.Stability Studies [30]:

The optimized prototype formulation (G10) was subjected to

stability studies for 03 months. The tablets were kept under three

conditions such as Alu/Alu blister, amber and an opened container

along with refrigerator for comparison with standard condition. The

tablets were evaluated at accelerated stability conditions (40±2 °C and

75±5% RH). No significant variation was observed that evidenced the

stability of formulation in terms of both, drug content and dissolution

profile i.e 86.26±0.45 - 100.13±0.44 in open container; 85.85±0.50 -

94.77±0.49 in blister packing and 90.85±0.61- 97.09±0.41 in amber

container respectively after 15 min of drug dissolution (Table 9).

Based on the results, it was concluded that the newly formulated

glimepiride tablets were stable after 3 months of storage at accelerated

stability conditions indicating good compatibility with the excipients

that were used in the formulation (Table 9).Stress Testing of Drug:

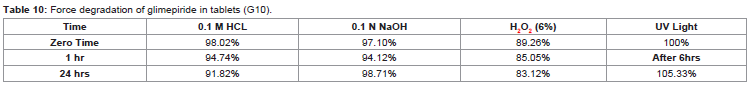

In the present study the degradations of glimepiride in tablet

dosage form (Formulation G10) were also done under different stress

conditions as per the ICH guideline [31]. The results of the study

indicated that the glimepiride underwent the slight degradation in

0.1N HCl whereas there were no changes observed in 0.1N NaOH,

H2O2 (6%) and UV light (Table 10).Conclusion

The concept, on which this study was based, was to develop an

oral dosage form with higher release rate in-vitro as compared to the

previous formulations made to attain the maximum bioavailability

possible. The model drug taken was glimepiride, an antidiabetic agent

BCS class II drugs with low solubility and high permeability. To

achieve our goal, a novel approach was designed for the enhancement

of dissolution rate. The strategy adopted was to develop slurry of

API with Tween 80, to reduce the surface tension between active

and Tween and to improve the solubility. It was concluded that the

present exploration indicates that it is not only a simple and easy

technique and could be used for large scale production but also has a

good capacity to improve the flow properties of material.

Acknowledgement

The authors would like to thank Dean of College and Department

of Pharmaceutics, RAK College of Pharmaceutical Sciences, RAK

Medical and Health Sciences University for continuous support

and encouragement.

References

22. Guidance for industry: Stability testing of new drug substances and products

(2003) ICH Q1A (R2).