Journal of Oral Biology

Download PDF

Research Article

Simulation of Soft Tissue in 3D-Printed Models for Guided Bone Regeneration Education

Wangsrimongkol Buddhapoom, Reis Natacha, Fernández-Guallart Ines,Yu Yung Cheng Paul*

Arthur Ashman Department of Periodontology and Implant Dentistry, New York University, USA

*Address for Correspondence: Cheng Yu PY, Department of Periodontology and Implant Dentistry, New York University, Clinic 5W, 345 E 24th St, New York, NY 10010, New York, USA, Tel: +1-3472792958; E-mail: ycy233@nyu.edu

Submission: 16-April-2020

Accepted: 06-June-2020

Published: 09-June-2020

Copyright: © 2020 Wangsrimongkol B, et al. This is an open access

article distributed under the Creative Commons Attribution License,

which permits unrestricted use, distribution, and reproduction in any

medium, provided the original work is properly cited.

Abstract

The use of custom-made 3D-printed models extracted from the Cone

Beam Computed Tomography (CBCT) of the patient provides the dentist

with the opportunity to rehearse a surgical procedure such as implant

placement enhancing its tactile simulation in order to achieve a predictable

and successful surgical outcome. Even the fact that these models have

substantially improved the preparation and education in implant surgery,

they lack the soft tissue layers necessary for simulating important procedures

such as periosteal releasing incisions and flap primary closure. For a more

realistic surgical simulation in implant education, the soft tissue layers of the

mucoperiosteal flap have been incorporated into the existent 3D-printed

model. The purpose of this report is to represent, describe, document and

discuss the recreation of the soft tissue layers of the mucoperiosteal flap on

a custom-made 3D-printed model extracted from the CBCT of the patient

in a case used to simulate a guided bone regeneration (GBR) procedure.

Introduction

Implant dentistry is one of the most popular modalities in the

dental field due to the high predictability and success rates of implants

when compared to conventional treatment options to replace missing

teeth in complete or partially edentulous patients [1-3].

In the last few years, new methods of diagnosis, treatment

planning and execution techniques in dentistry have been developed

or improved due to the advances in technology. Examples of this are

the evolution of digital dental imaging from two-dimensional (2D)

to three-dimensional (3D) images, the creation of digital dental

impressions (intraoral scans), digital treatment planning (virtual

software), digital guidance for surgery (computer-guided surgery)

and digital 3D production (Computer-Aided Design/Computer-

Aided Manufacturing - CAD/CAM). Also, the recent advances in

digital imaging such as Cone Beam Computed Tomography (CBCT)

are improving the visualization, now with great details of the patient’s

anatomy in 3D when compared with standard radiographs, which are

taken and seen in 2D [3].

As implant dentistry is becoming more widely practiced, effective

continuous education is becoming very important, especially

regarding the fact that implant dentistry as a main subject is usually

not taught in undergraduate courses of dental schools, so clinicians

who are going to practice it find the need for learning it afterwards

either in postgraduate programs, advanced education training or

weekend courses, among others. Mainly, this education is based on

pre-clinical hands-on practice followed or not by clinical training. To

design and perform a hands-on, several materials and methods can

be used (typodonts, models from the mouth, animal jaws and human

cadavers, among others). From these, the use of 3D-printed models extracted from patient’s CBCT is becoming a well-accepted method

of education because it allows to accurately simulate the real patient

anatomy, especially in terms of hard tissues (teeth and bone), so

procedures such as implant placement can be successfully practiced

on them. However, the simulation of a complete implant surgical

procedure with all its steps (incisions design, flap elevation, osteotomy,

implant placement and suture, and in some cases, additional guided

bone/tissue regeneration and/or sinus augmentation) is not possible

in CBCT-based 3D-printed model hands-on due to a lack of soft

tissues in these models, which management is of vital importance to

achieve clinical success [4,5].

Although the use of 3D-printed models is already established

worldwide for surgical simulation in terms of education in implant

dentistry, there is still shortage in publications regarding the best

material for fabrication of soft tissues for these models. Park et al.

(2017) reported the combination of vinyl tape, sponge tape and liquid

tape to mimic the soft tissue in a 3D-printed model. However, there

is a limitation in terms of the amount of periosteal releasing and

consequential flap advancement that can be achieved in this option,

which is only 1-2 mm. In the new prototype presented in this article

it was possible to gain 5-10 mm (similar to what can be achieved in

a real patient), which is crucial for the achievement of tension-free

primary closure [6].

The purpose of this report is to represent, describe, document and

discuss the recreation of the soft tissue layers of the mucoperiosteal

flap on a custom-made 3D-printed model extracted from the Cone

Beam Computed Tomography (CBCT) of the patient in a case used to

simulate a guided bone regeneration (GBR) procedure.

Materials and Methods

The steps for producing a 3D-printed model and simulating a

surgical guided bone regeneration procedure on it are

1. Obtain a patient’s CBCT scan using a CBCT imaging

system (J. Morita, Kyoto, Japan), in which the field of view (FOV)

of the image will be selected depending on the area of interest of the

case.

2. Convert the Digital Imaging and Communications Stereolithography (STL, OsiriX Lite, Geneva, Switzerland) format.

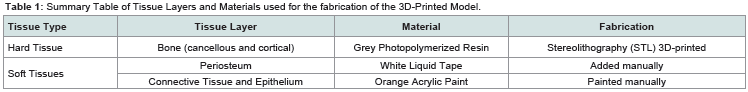

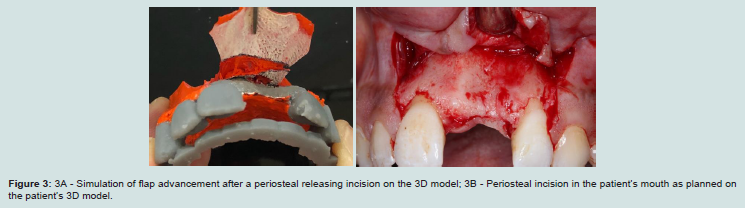

Table 1: Summary Table of Tissue Layers and Materials used for the fabrication of the 3D-Printed Model.

3. Process and print the STL file with a 3D- printer (Formlab

Form 2 Printer, Somerville, Massachusetts, USA), using a grey

methacrylic photoreactive liquid resin material that represents the

hard tissue of the 3D-printed model.

4. Add acrylic paint to simulate soft tissue layers: periosteum

is recreated with liquid tape and connective tissue and epithelium

are reconstructed with orange acrylic paint, painted manually on the

surface of the 3D-printed model (Table 1).

5. A full-thickness midcrestal incision is made between the

teeth adjacent to the defect. Two vertical incisions are made parallel

or trapezoidal until the base of the flap, widening apically for easy

coronal repositioning of the flap after augmentation with the graft

material. After passing the imaginary mucogingival junction, the

vertical incisions continue apically in a vertical or more convergent

direction.

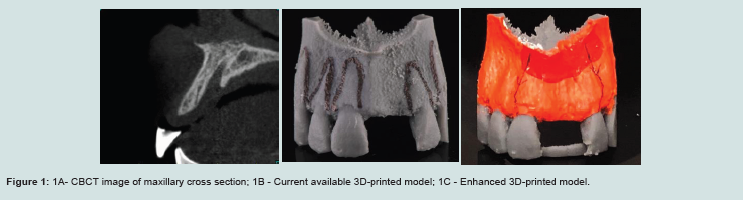

6. The liquid tape with orange acrylic paint is then elevated

with a periosteum elevator.

7. Cortical perforation (decortication) is performed by #1 or

#2 round bur using high speed hand piece with copious irrigation.

8. Releasing incisions are made with a sharp 15C blade on

the inner apical portion of the liquid tape and orange acrylic paint,

creating a 2-3mm split-thickness dissection.

9. Tinfoil is used as a template, and in this case also as a mimic

of the collagen membrane, fitted and trimmed to the ideal shape, and

then put to the correct position. A single tack is positioned apically

through the membrane into the photopolymerized resin, and the

membrane is rotated 180 around the tack and adjusted to extend

2-3mm beyond the augmented area. The graft material is placed and

condensed to fill the defect.

10. Stabilization of the membrane and the underlying graft

material is achieved by using horizontal mattress sutures extending from the apical portion of the liquid tape to the palatal aspect of the

orange acrylic paint. Consequently, the liquid tape is then coronally

advanced together with the orange acrylic paint, allowing tensionfree

closure afterwards.

Finally, the complete adaption of the orange acrylic paint is

achieved by multiple interrupted 4-0 chromic gut sutures.

In this case, the area of interest was the anterior maxilla, an

aesthetic area where soft tissue management is usually necessary.

Figure 1A shows the patient CBCT, where it is possible to appreciate

the selected area for the guided bone regeneration (GBR) surgical

simulation. The DICOM file was processed and the STL file was

printed obtaining the patient 3D-model using a grey methacrylic

photoreactive liquid resin material to mimic the hard tissue of the

patient, as it is shown in Figure 1B. After the 3D- model was printed,

the soft tissue layers needed for simulation of soft tissue management

during GBR were fabricated using acrylic paint and white liquid tape.

In this specific prototype, orange acrylic paint was used to reproduce

the epithelium and connective tissue and liquid tape to reproduce the

periosteum, as shown in Figure 1C (the white layer was the first one

to be painted on the 3D model, and the orange layer was painted over

it [Figure 2A]). In Table 1, the description of 3D model layers can be

appreciated.

Results

In the present case report, the surgical procedure of GBR

technique was performed successfully after the dentist did simulation

and practised the surgery sequence in the enhanced 3D model.

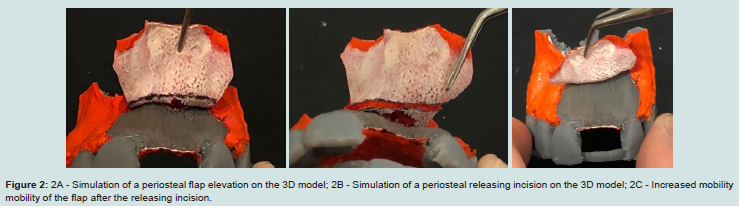

Figure 1B shows the hard tissues 3D model. Figure 1C shows

the soft tissues 3D-printed model with the incisions design. Figure 2A shows flap elevation after midcrestal, mesial and distal incisions. Figure 2B shows the periosteum releasing for flap advancement. Figure 2C shows the increased mobility of the flap to achieve tensionfree primary closure. Figure 3A shows the occlusal view of the

advancement of the flap in the 3D model, similar to the one achieved in the patient’s mouth (Figure 3B).

Figure 1: 1A- CBCT image of maxillary cross section; 1B - Current available 3D-printed model; 1C - Enhanced 3D-printed model.

Figure 2: 2A - Simulation of a periosteal flap elevation on the 3D model; 2B - Simulation of a periosteal releasing incision on the 3D model; 2C - Increased mobility mobility of the flap after the releasing incision.

Discussion

Nowadays, with the advances in technology, 3D imaging

techniques are replacing 2D imaging techniques, especially in

complex cases due to the need for better details of anatomy. CBCT

scan is a 3D digital imaging technique that uses ionizing radiation

(x-ray), although when compared with conventional CT scan it

is less invasive in radiation exposure and has higher quality. The

principle of the CBCT image is that higher density of the tissue

equals to higher absorption of the radiation, so the performance in

hard tissue imaging is higher than in soft tissue. CBCT is becoming

more popular in implant dentistry due to the accurate visualization

of hard tissues needed for implant treatment planning and moreover

the possibility of virtual simulation of the implant position in relation

to neighboring structures when introducing the CBCT data into

a planning software. Magnetic Resonance Imaging (MRI) is a 3D

digital imaging technique using non-ionizing radiation, which basic

principle is the interaction between static magnetism and hydrogen

atoms. Consequently, the higher amount of hydrogen atoms in the

tissues, the higher density. Higher quantity of hydrogen atoms is

found in tissues with higher quantity of water, so the performance

in soft tissue imaging is higher than in hard tissues. In comparison

with CBCT, the imaging resolution of hard tissue is lesser, and it is

also more expensive [7-9]. Both hard and soft tissue information

are essential to produce a 3D-printed model. However, CBCT scan

is preferable to MRI because without a highly precise hard tissue

information from the real patient it is not possible to fabricate an

actual 3D-printed model for surgery simulation.

Implant placement is a very straightforward surgical procedure in cases having enough bone width and height as well as healthy

soft tissue. However, in more complex cases there is a need for

reconstructing bony and soft tissue defects. TThere are several

techniques for bone augmentation such as guided bone regeneration

(GBR) with the use of membranes in combination to autogenous

bone grafts, allografts and/or xenografts. To enhance its results bone

promoting proteins (BPPs), or platelet rich plasma (PRP) can be

used. Other techniques include inlay and onlay grafts, ridge splinting,

and distraction osteogenesis among others. On the other hand, for

soft tissue augmentation, there are also numerous techniques such

as autogenous grafts (free gingival, connective tissue grafts), or the

use of allogenic, xenogenic and synthetic materials. In all of these

techniques, soft tissue management is needed in terms of incision

making, flap elevation and suturing [10,11].

Soft tissue management is important for a proper healing of the

bone and soft tissue. Flap design with correct incisions is important

for bony defect access, sustainability of the blood supply from the

base of the flap, papillae preservation and free-tension primary

closure allowance among others. After elevating a full-thickness

mucoperiosteal flap, especially in cases of ridge augmentation, it is

imperative to either stretch the elastic fibers present in the mucosa,

or do a horizontal periosteal releasing incision in the apical part of

the flap to increase the stretchability of the tissue in order to allow

it to be advanced and cover all the surgical site, thus achieving the

so-called tension-free primary closure. Primary closure should be

tension-free in order to avoid pressure on the graft materials which

can cause postoperative swelling, as well as to allow microvascular

anastomosis for re-epithelization and fully wound closing, enhancing

the re-establishment of the blood supply [12-14].

Conclusion

The use of 3D-printed models from CBCT images had several

advantages in surgical simulation and training in the past in

comparison to standard models and other hands-on modalities.

CBCT scans are more favorable than MRI in terms of achieving

hard tissues visualization in 3D and transferring it to a 3D model.

However, the recent challenge is the addition of soft tissues into the

3D models. This new issue is required due to the importance of soft

tissue management in many procedures in implant dentistry, and thus

a proper 3D model prototype should simulate the soft tissue layers:

periosteum, connective tissue and epithelium. This new 3D model

prototype provides an excellent hands-on for educational purposes,

as it allows the practitioner to study, simulate and rehearse several

times the soft tissue management procedure until he/she the reaches

the expected level of confidence, since multiple replicas of soft tissues

layers can be fabricated. In the next coming years, with the integration

of MRI into CBCT, the production of even more realistic soft tissue

architecture for surgical simulation seems possible. However, despite

the promising results of the proposed 3D enhanced model, further

investigations at a higher level of evidence are necessary to validate

this proposed 3D model.