Journal of Food Processing & Beverages

Download PDF

The diluted distillate, along with alcoholometers and a 500 mL graduated cylinder, was placed in an incubator maintained at 20°C for one hour to allow thermal equilibration. Following incubation, the equipment and distillate were transferred to an air-conditioned room at 20°C for measurement.

• C is the methanol concentration in the beverage (mg/L),

• q is the daily consumption volume (L/day),

Pc is the conventional adult body weight (70 kg), as defined by the WHO and FAO Environmental Health Criteria 240 (World Health Organization & Food and Agriculture Organization of the United Nations, 2009). [10]

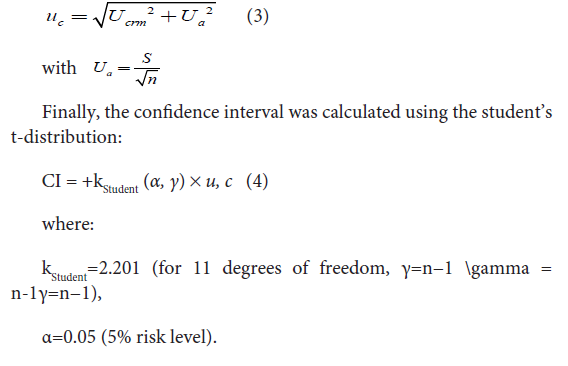

The specificity of the developed method was assessed by testing compounds likely to be present in alcoholic beverages, including glucose, butanol, and propanol, each at 10 mg/L. As presented in [Table 1], none of these compounds produced a signal above the limit of quantification (LOQ), indicating that they do not interfere with methanol detection. In contrast, samples containing methanol, whether alone or mixed with propanol or butanol, showed measured concentrations close to the expected values (9.50–10.27 mg/L for 10 mg/L methanol solutions and 4.88 mg/L for 5 mg/L methanol solutions). These results confirm that the method specifically detects methanol without significant cross-reactivity from other alcohols or hydroxylated compounds, thus ensuring the reliability of measurements in complex beverage matrices.

Research Article

Assessment of Methanol Levels and Labeling Irregularities in Alcoholic Beverages from Yaounde Markets

Songue SO1*, Ekani V2, Tiendo PS1, Mbassi JEG3 and Sado S2

1Hygiene and Environment Department, Physocochemistry Section,

Centre Pasteur du Cameroun

2University of Yaounde 1, Department of biochemistry, Cameroon.

3Institute of Agricultural Research for Development (IRAD), Cameroon.

2University of Yaounde 1, Department of biochemistry, Cameroon.

3Institute of Agricultural Research for Development (IRAD), Cameroon.

*Address for Correspondence:SONGUE SAME Olivier, Hygiene and Environment department,

physicochemical section, Centre Pasteur du Cameroun (CPC). E-mail Id: songueolivier@gmail.com

Submission: 15 August 2025

Accepted: 09 September 2025

Published: 12 September 2025

Accepted: 09 September 2025

Published: 12 September 2025

Copyright: © 2025 Songue SO, et al. This is an open access article

distributed under the Creative Commons Attribution License, which

permits unrestricted use, distribution, and reproduction in any medium,

provided the original work is properly cited.

Keywords:Methanol; Alcoholic Beverages; Public Health; Food

Safety; Labeling Compliance

Abstract

This study investigates methanol contamination and labeling

compliance in alcoholic beverages marketed in Yaoundé, Cameroon.

A total of 106 beverages, including spirits, wines, and traditional

drinks, were analyzed. Methanol quantification was performed

using a modified chromotropic acid spectrophotometric method,

while alcohol content was determined by distillation followed by

aerometry. Results revealed that 32.1% of beverages exceeded the

European Union’s methanol safety limit of 50 mg/L, although none

reached the acute toxicity threshold of 2000 mg/L (14 mg/kg bw/day).

Labeling analysis showed that 13.5% of samples had alcohol content

discrepancies, and 16% lacked proper alcohol labeling, particularly

among traditional beverages. Additionally, major traceability gaps,

such as missing or repeated batch numbers, were observed. While

acute methanol poisoning risk appears low, the potential long-term

health impacts of chronic low-level exposure remain concerning,

especially for heavy consumers. The findings highlight the urgent

need for national methanol regulations, stricter labeling enforcement,

systematic beverage monitoring, and public awareness initiatives to

ensure consumer safety and support public health policy development

in Cameroon.

Introduction

The celebration of both joyful and somber events is often

accompanied by the consumption of alcoholic beverages such as

beer, wine, or spirits. Additionally, some individuals consume alcohol

recreationally or as a means of escaping reality, potentially leading

to dependence or addiction (Institut National de la Santé et de la

Recherche Médicale, 2023). [1] In 2016, alcohol consumption ranked

as the seventh leading cause of global mortality, accounting for more

than three million deaths (Matene Fongang, 2020) [2]. Cameroon is

recognized as the largest consumer of alcohol in Central and West

Africa. In 2016 alone, Cameroonians consumed over 660 million liters

of beer (Matene Fongang, 2020) [2]. Globally, more than a quarter of

alcohol consumption is unrecorded, illicit, or undeclared (Manning

& Kowalska, 2021; Probst et al., 2018) [3,4]. In developing countries

such as Cameroon, in addition to industrially produced or imported

beverages, traditional alcoholic drinks are commonly available; these

are often produced with limited mastery of manufacturing practices

(Kubo et al., 2014) [5].

Illicit, adulterated, and poor-quality alcoholic products pose

serious risks to public health and safety (Manning & Kowalska, 2021)

[3]. The lack of strict control over the production process can lead to

contamination by harmful substances such as methanol. Methanol

(CH₃OH) is a volatile, flammable primary alcohol characterized by a

slightly sweet taste and an odor similar to that of ethanol. Methanol

in fermented and alcoholic beverages may have a natural origin,

resulting from specific fermentation techniques (Aït Daoud et al.,

2021; Destanoğlu & Ateş, 2019; Hodson et al., 2017; Ohimain, 2016;

Tomsia et al., 2022) [6-9]. However, cases of intentional methanol

addition to beverages have been reported, primarily aimed at

artificially increasing alcohol content and reducing production

costs, often targeting financially vulnerable consumers [7] (Hodson

et al., 2017; World Health Organization & Food and Agriculture

Organization of the United Nations, 2009) [7,10]. Mass poisonings by

methanol-containing liquids have been reported from Russia (Jargin,

2017) [11].

Clinical manifestations of methanol intoxication range

from symptoms of drunkenness, gastrointestinal disorders,

ocular complications (e.g., optic neuritis), to metabolic and

neuropsychiatric disturbances, which may resolve spontaneously

within a few hours to days post-ingestion (Sanaei-Zadeh, 2012)

[12]. In severe cases, symptoms such as mild mydriasis, bilaterally

non-reactive pupils, and profound metabolic acidosis can occur.

Methanol ingestion represents a major health hazard due to its

potential to cause irreversible organ damage or death if not treated

promptly (Ohimain, 2016; Sanaei-Zadeh, 2012; Tomsia et al.,

2022). [8,12,9] In light of these health risks, various countries have

established regulatory limits for methanol concentrations in alcoholic

beverages. Since 2008, the European Union (EU) has set maximum

allowable methanol concentrations (per liter of pure ethanol) at

13.5 g/L for fruit brandies, 10 g/L for pomace brandies, and 2 g/L

for citrus brandies (Botelho et al., 2020) [13]. In the United States,

Australia, and New Zealand, the limit for spirits and fruit brandies is

7 g/L (Botelho et al., 2020) [13]. Regarding wines, the International

Organization of Vine and Wine (OIV) recommends maximum

methanol concentrations of 250 mg/L for white and rosé wines,

and 400 mg/L for red wines (Thanasi et al., 2024) [14]. The OIV

also mandates specific labeling requirements for wines and spirits,

including the product name, actual alcohol content, batch number,

and responsible producer’s identification (Thanasi et al., 2024) [14].

Physicochemical analyses are essential to ensure both the

accuracy of labeled alcohol content and the absence of harmful

levels of contaminants such as methanol. Several analytical methods

have been developed for methanol detection, including Fourier

Transform Infrared Spectroscopy (Sharma et al., 2009) [15], Raman

Spectroscopy (Boyaci et al., 2012), [16] enzymatic assays (Kučera

& Sedláček, 2017), [17] electrochemical sensors (Kavita et al.,

2022), liquid chromatography (Albaseer & Dören, 2022) [18], gas

chromatography (Sharma et al., 2009; Zamani et al., 2019) [15,19],

and spectrophotometry (Ghadirzadeh et al., 2019; Zamani et al.,

2019) [20,19]. Currently, gas chromatography is recognized as the

gold-standard method for the determination of volatile alcohols in

beverages according to European Commission Regulation (EC) No.

2870/2000, due to its specificity and high sensitivity (Zamani et al.,

2019). [19] However, its high operational cost, the requirement for

rare gases, and the need for highly specialized personnel limit its

routine application in developing countries.

Spectrophotometry using chromotropic acid has been proposed

by the OIV as a low-cost alternative for methanol analysis in wines and

spirits, although the method remains a Type IV analytical method. A

Type IV Method or Tentative Method is a method which has been

used traditionally or else has been recently introduced but for which

the criteria required for acceptance by the Codex Committee on

Methods of Analysis and Sampling have not yet been determined

(Codex Alimentarius, 2019). [21] Recent studies have enhanced this

method, demonstrating acceptable sensitivity and quantification

limits when compared to gas chromatography (Ghadirzadeh et al.,

2019; Zamani et al., 2019). [20,19]

The present study aims to assess the exposure risk to methanol

among populations in Yaoundé through the consumption of

alcoholic beverages. This represents the first investigation of its kind

in Cameroon and establishes a foundation for broader research on

methanol contamination in the country. The findings also advocate

for the implementation of systematic regulatory controls using cost effective

analytical kits.

Methodology

Reagents:

The following reagents were used in this study: chromotropic

acid, ethanol (100%), methanol (99.9%), and sodium metabisulfite

(98%) were purchased from VWR Chemicals (Europe, France).

Phosphoric acid (85%), potassium permanganate (>99.5%), and

sulfuric acid (98%) were obtained from MERCK (Europe, Germany).

The prepared solutions were:

- Chromotropic acid solution (0.05% in 75% sulfuric acid v/v):

Dissolve 50 mg of chromotropic acid (or its sodium salt) in35 mL of distilled water. Cool the solution in an ice bath, then

carefully add 75 mL of concentrated sulfuric acid (density

1.84 g/mL) in small portions while stirring continuously.

- Standard methanol solution: 0.5 g/L methanol prepared in

5% (v/v) ethanol.

- Dilution solution: 50 mL of absolute ethanol diluted to 1 L

with distilled water.

Equipment:

The actual alcohol content of the beverages was determined using

a RAYPA distiller (ENODES, Spain). All weighings were performed

with an Adventurer SL analytical balance (OHAUS, Switzerland)

with a precision of four decimal places. Alcohol content of the

distillates was measured using a series of alcoholometers (ranges

0–10, 20–30, 30–40, and 40–50) supplied by ALLA (ALLA-France,

France). Methanol quantification was carried out with a Jenway 7205

UV-Visible spectrophotometer (Cole-Parmer Ltd, UK) following its

reaction with chromotropic acid. Samples and analytical equipment

were stored at 20°C in a Bio Expert refrigerated incubator (Froilabo,

France).Samples:

Samples of wines, spirits, and traditional beverages were collected

from July to November 2018 and from June to October 2023 at the

Mokolo Market (GPS: 3.8742049 N, 11.502111 E) in Yaoundé, the

capital city of Cameroon. Mokolo Market is one of the largest and

most populous marketplaces in Central Africa. Beverage brands

were selected based on a preliminary survey conducted with

market vendors to identify the most frequently consumed products.

A total of 106 samples were purchased, representing approximately

80% of the most popular brands across wines, spirits, and traditional

beverages. For each brand, three bottles were acquired. The batch

number, labeled alcohol content, nominal volume, manufacturer

information, and production and expiration dates were recorded

for each sample. To maintain confidentiality, brand names are not

disclosed in this study.Specifically, 60 spirit brands, 36 wine brands, and 10 types of

traditional beverages were sampled. The products were transported

at ambient temperature in containers shielded from direct sunlight

and placed in secure areas of the transport vehicle to prevent physical

damage. Upon arrival, samples were stored in air-conditioned rooms

maintained at 20°C to minimize methanol volatility at elevated

temperatures (>60°C).

Determination of the Actual Alcohol Content of Beverages:

The actual alcohol content of the beverages was determined using

a distillation followed by aerometry method. In this procedure, 200

mL of each beverage sample was distilled using the RAYPA distiller.

The distillate was collected in a 500 mL volumetric flask and diluted

to the mark with ultra-pure water.The diluted distillate, along with alcoholometers and a 500 mL graduated cylinder, was placed in an incubator maintained at 20°C for one hour to allow thermal equilibration. Following incubation, the equipment and distillate were transferred to an air-conditioned room at 20°C for measurement.

The distillate was carefully poured into the graduated cylinder,

and an alcoholometer was immersed into the liquid. Once the

alcoholometer stabilized, standing perpendicular to the surface, the

reading at the liquid interface was recorded. The recorded value was

multiplied by 2.5 to calculate the actual alcohol content of the original

beverage. The selection of the alcoholometer was based on the

expected alcohol content: the first alcoholometer used corresponded

to a range approximately 2.5 times lower than the labeled alcohol

percentage. If the alcoholometer was completely submerged, a lower range

instrument was selected; conversely, if it floated excessively with

no readable graduation at the surface, a higher-range alcoholometer

was employed.

Each measurement was performed in duplicate to ensure

reliability. Based on the determined alcohol content, the distillate

was further diluted as needed to reach an approximate 5% alcohol

concentration for subsequent analytical procedures.

Methanol Quantification in Beverages:

The quantification of methanol was based on its oxidation to

formaldehyde by potassium permanganate acidified with phosphoric

acid, using beverage distillates diluted to 5% (v/v) alcohol. The

resulting formaldehyde reacts with chromotropic acid to form a

purple-colored complex, which absorbs maximally at 575 nm. The

absorbance intensity is proportional to the methanol concentration,

as measured by UV-Visible spectrophotometry.The method applied in this study is a modification of the

procedure described by Ghadirzadeh et al., (2019). [20] The principal

modification consists of introducing an ice water bath step prior

to the addition of saturated potassium permanganate to prevent

formaldehyde volatilization and ensure greater reaction stability.

Calibration standards were prepared by diluting 100% methanol

into 5% (v/v) ethanol to achieve a stock solution of 500 mg/L

methanol. Serial dilutions were then performed by introducing 2.5,

5, 10, 15, 20, and 25 mL of the stock solution into 50 mL volumetric

flasks, corresponding to final methanol concentrations of 25, 50, 100,

150, 200, and 250 mg/L, respectively.

For quantification, 500 μL of either a standard solution or a

beverage distillate adjusted to 5% (v/v) alcohol was transferred into

test tubes. The volume was brought up to the gauge mark with 5%

ethanol (prepared by diluting absolute ethanol with ultra-pure water).

Subsequently, 50 μL of 50% phosphoric acid was added to each tube.

After cooling the tubes in an ice bath, 100 μL of saturated potassium

permanganate solution was added. Following a 10-minute reaction

time, the excess permanganate was decolorized with 100–200 μL of a

2% neutral sodium sulfite solution.

Then, 5 mL of a 0.05% chromotropic acid solution in 98% sulfuric

acid was added to each tube. The tubes were incubated in a water

bath at 70°C for 20 minutes, then cooled to room temperature for 20

minutes before absorbance measurements were performed at 575 nm.

All measurements were conducted in duplicate to ensure analytical

reliability.

Method Validation and Quality Control:

All glassware was washed with a mild detergent, rinsed three

times with tap water, and subsequently rinsed twice with ultra-pure

water prior to use. The linearity of the method was evaluated based

on calibration curves constructed from methanol standard solutions

at concentrations of 25, 50, 100, 150, 200, and 250 mg/L. Regression

lines were generated by plotting concentration against optical density

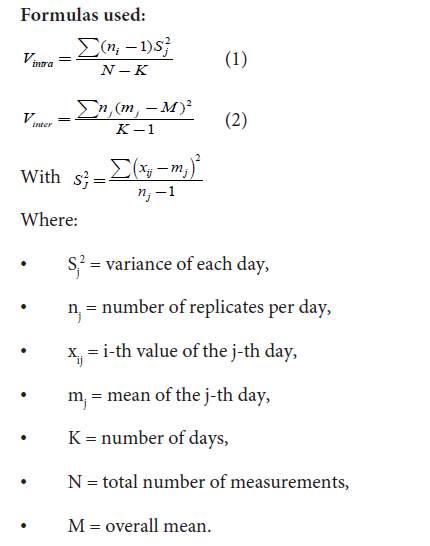

values obtained after chromotropic acid complexation.Precision was assessed at three concentration levels; each tested

in quadruplicate within a single day to evaluate intra-day variability

(Equation 1). Intermediate (inter-day) precision was determined by

repeating the same spiking tests on two additional, separate days,

allowing calculation of inter-day variance (Equation 2). Both intraday

and inter-day precision were expressed as coefficients of variation

(CV, %).

To verify the absence of contamination during distillation,

blank tests were performed using 5% (v/v) ethanol prepared

with ultra-pure water in place of beverage samples.

Limits of detection (LOD) and quantification (LOQ) were calculated

by analyzing ten blank samples. The LOD was defined as the mean

blank value plus three times the standard deviation (SD), and the

LOQ as the mean plus ten times the SD.

The maximum method bias was determined as the percentage deviation between the mean spiked sample recovery and the expected theoretical value based on the calibration curve.

The maximum method bias was determined as the percentage deviation between the mean spiked sample recovery and the expected theoretical value based on the calibration curve.

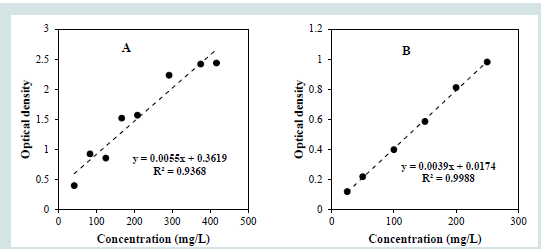

The maximum uncertainty was calculated based on the 95%

confidence interval (CI) of the precision tests. Initially, uncertainty

of certified reference material (ucrm) was read directly on the label of

standard solutions. Then, expanded uncertainty of certified reference

material (Ucrm) was determined by multiplying ucrm by two (Ucrm

= 2 × ucrm). Random uncertainty (Ua) and combined uncertainty

(Uc) were then calculated as follows:

Evaluation of Human Exposure:

Human exposure to methanol through the consumption of

alcoholic beverages was estimated using the following equation:

E=C q

p´

Where :

• E is the exposure value expressed in μg/kg body weight (bw)

per day,• C is the methanol concentration in the beverage (mg/L),

• q is the daily consumption volume (L/day),

Pc is the conventional adult body weight (70 kg), as defined by the WHO and FAO Environmental Health Criteria 240 (World Health Organization & Food and Agriculture Organization of the United Nations, 2009). [10]

Pc is the conventional adult body weight (70 kg), as defined by the

WHO and FAO Environmental Health Criteria 240 (World Health

Organization & Food and Agriculture Organization of the United

Nations, 2009). [10]

The daily consumption value (q) was set at 500 mL (0.5 L) per person, based on data from the National Institute of Statistics (INS) and as reported by Ingenbleek et al., (2017), [21] representing the intake pattern of heavy consumers.

The daily consumption value (q) was set at 500 mL (0.5 L) per person, based on data from the National Institute of Statistics (INS) and as reported by Ingenbleek et al., (2017), [21] representing the intake pattern of heavy consumers.

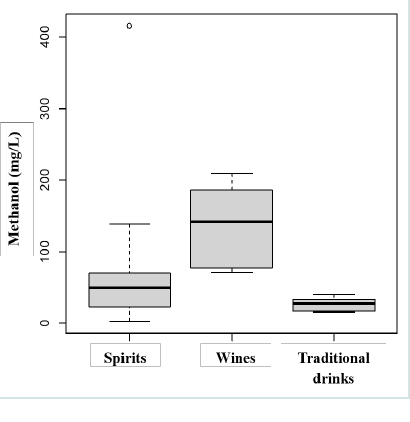

Data Processing and Statistical Analysis:

Data analysis was performed using Microsoft Excel 2016,

primarily for plotting calibration curves and calculating descriptive

statistics (means, standard deviations, coefficients of variation).

Variance analysis (ANOVA) and box plot visualizations were carried

out using R software, version 4.0.2, to assess differences between

beverage categories and to support statistical interpretations of

methanol concentration distributions.Results and Discussion

Choice of Method:

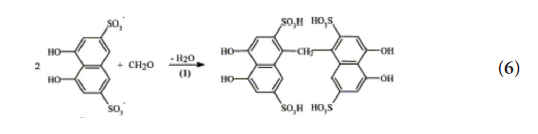

The type IV method described by the International Organization

of Vine and Wine OIV (Codex Alimentarius, 2019; OIV, 2009)

[21,23] was modified by introducing a cooling step prior to the

addition of potassium permanganate to improve method stability

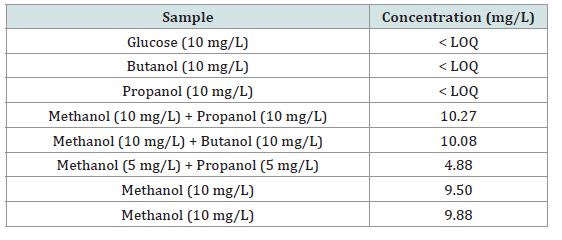

and linearity [Figure 1]. In the conventional method [Figure 1A], the

calibration curve shows moderate linearity (R² = 0.9368), likely due

to the volatility of methanal formed during the reaction, especially

at temperatures above 25°C. This volatility leads to variability in the

amount of methanal available for reaction with chromotropic acid,

compromising reproducibility.After modification, the calibration curve (Figure 1B) exhibits

significantly improved linearity (R² = 0.9988) over the concentration

range of 2.5–250 mg/L. The cooling step minimizes methanal loss

by volatilization, leading to a more stable and reliable analytical

response. Thus, the modified method offers enhanced precision and

accuracy for methanol quantification in alcoholic beverages.

Verification of the Performance of the Chosen Method:

• SpecificityThe specificity of the developed method was assessed by testing compounds likely to be present in alcoholic beverages, including glucose, butanol, and propanol, each at 10 mg/L. As presented in [Table 1], none of these compounds produced a signal above the limit of quantification (LOQ), indicating that they do not interfere with methanol detection. In contrast, samples containing methanol, whether alone or mixed with propanol or butanol, showed measured concentrations close to the expected values (9.50–10.27 mg/L for 10 mg/L methanol solutions and 4.88 mg/L for 5 mg/L methanol solutions). These results confirm that the method specifically detects methanol without significant cross-reactivity from other alcohols or hydroxylated compounds, thus ensuring the reliability of measurements in complex beverage matrices.

Figure 1:Calibration curves for the quantification of methanol using (A) the

conventional OIV method and (B) the modified OIV method.

It is evident that chromotropic acid reacts only with methanal

according to Equation (6) described by Fagnani, (2003). [24] It does

not react with other forms of aldehyde.

However, if the drink that is to react with chromotropic acid is

the result of fermentation that induces the production of formic acid

or formaldehyde, the latter will also govern. In this case, we see false

positive results (Zamani et al., 2019) [19].

• Limits of Detection and Quantification:

The tests conducted ten times with the blank (0.5% ethanol

alcoholic solution) allowed for the calculation of the mean and

standard deviation, necessary for determining the limits of

quantification (LOQ) and detection (LOD) (Section 2.6). It appears

that the limits of quantification and detection are 2.68 mg/L and 0.81

mg/L, respectively. Considering the methanol content in beverages

commonly viewed in the literature (>5 mg/L), the quantification and

detection limits of the method are therefore appropriate. They are

comparable to the detection limits presented by (Ellis et al., 2019) [25]

in their work on the quantification of methanol in counterfeit spirits

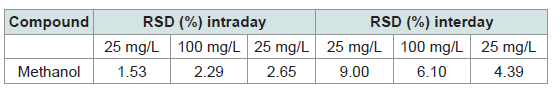

using Raman spectroscopy.• Precision, Uncertainties, and Bias:

The precision of the method was evaluated through intra-day

and inter-day repeatability tests at concentrations of 25 mg/L and

100 mg/L [Table 2]. The intra-day relative standard deviations

(RSD) were 1.53% and 2.29% for 25 mg/L and 100 mg/L methanol

solutions, respectively, while inter-day RSDs were 2.65% and 9.00%.

These values are all below the generally accepted threshold of 10%,

confirming good repeatability and intermediate precision of the

method. The highest variability was observed in the inter-day test

at 100 mg/L, yet it remained within acceptable limits for analytical

methods. Overall, the low RSD values demonstrate that the method

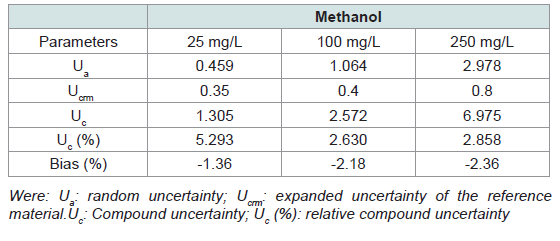

produces reliable and consistent results under the tested conditions.[Table 3] also presents the uncertainties and bias of the

method. Bias and uncertainty tests demonstrated that the methanol

quantification method maintained good analytical performance

across all concentration levels. Relative combined uncertainties

(Uc%) remained below 6%, and biases ranged from –1.36% to

–2.36%, indicating slight but acceptable underestimations. These

results confirm the method’s accuracy and suitability for reliable

methanol analysis in alcoholic beverages.

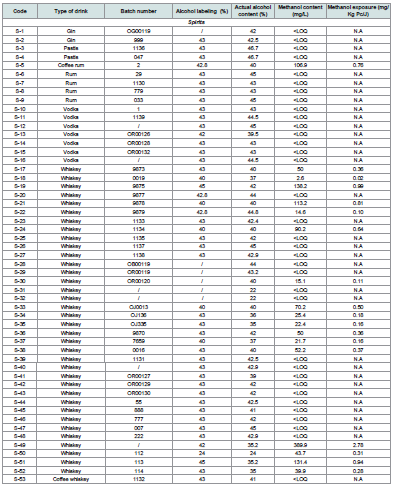

Ethanol and Methanol Content in Beverages: Exposure Evaluation:

The analysis of 106 alcoholic beverages, including 60 spirits, 36

wines, and 10 traditional drinks, revealed considerable variability in

methanol content depending on the beverage type [Table 4]. Among

the spirits, 64.1% of samples had methanol concentrations below

the limit of quantification (LOQ), whereas 35.9% showed detectable

levels, with concentrations reaching up to 138.2 mg/L. Although

these levels remained below the acute toxicity threshold of 2000 mg/L

(Ohimain, 2016),[8] several whiskey samples exceeded the European

Union’s recommended safety limit of 50 mg/L, suggesting potential

risks related to uncontrolled distillation practices or adulteration

(Ellis et al., 2019). [25]Almost half of the red wine samples (47.4%) exhibited methanol

concentrations above 100 mg/L, with the highest recorded value

reaching 206.5 mg/L. Nevertheless, all wine samples complied with

the OIV regulatory limits for methanol content in red (500 mg/L)

and white wines (250 mg/L) (Thanasi et al., 2024). [14] The elevated

methanol levels in wines are likely associated with pectin degradation

during fruit fermentation, a natural source of methanol production

(Md et al., 2013; Navianti et al., 2018). [26,27][28,29]

Traditional beverages, particularly palm wine and odontol,

generally exhibited lower methanol concentrations, ranging from

14.5 to 40.3 mg/L. However, most palm wine samples exceeded limit

fixed by National Agency for Food, Drug Administration and Control

(NAFDAC) (5 mg/L) for traditional alcoholic beverages (Ohimain,

2016). [8] The absence of specific national standards for methanol

content in Cameroon allows such practices to persist, affecting local

consumer safety and complicating exports to neighboring countries

with stricter regulations.

Labeling and traceability assessments also revealed major

deficiencies: 13 beverages (13.5%) showed discrepancies between the

actual and declared alcohol content, while 17 samples (16%), mainly

traditional beverages, lacked any alcohol labeling. Additionally, 15%

of spirits and 39% of wines were missing batch numbers, and some

producers assigned identical batch numbers across different brands,

suggesting possible fraud or at least poor-quality control practices.

Regarding health risk assessment, the estimated methanol

exposure from beverage consumption ranged from 0.02 to 1.48 mg/

kg body weight/day. Although these values remained well below the

lethal exposure threshold of 14 mg/kg body weight/day (Ohimain,

2016) [8], chronic low-dose exposure could pose long-term health

risks, particularly targeting the central nervous system and visual

pathways (Sanaei-Zadeh, 2012) [12].

Variance analysis [Figure 2] showed no significant differences

between the methanol contents of spirits and wines (P = 0.126) or

between spirits and traditional beverages (P = 0.099). However, a

significant difference was observed between wines and traditional

beverages (P = 0.0003), reflecting greater variability in spirit

formulations, particularly among whiskeys of various types (e.g.,

fruity, skimmed, coffee-flavored varieties).

Overall, these findings underscore the urgent need for Cameroon

to establish national regulations governing methanol content in both

industrial and traditional alcoholic beverages. In addition, systematic

monitoring, stricter labeling enforcement, and public awareness

initiatives are essential to protect public health. The significant

variability in methanol concentrations, combined with widespread

labeling non-compliance, highlights an urgent call for regulatory

action. The key implications and recommendations arising from this

study are discussed in the following conclusion.

Conclusion

This study provides a comprehensive evaluation of methanol

contamination and labeling compliance in alcoholic beverages sold

in Yaoundé, Cameroon. Results showed that 32.1% of beverages

contained methanol levels exceeding the European Union’s safety

threshold of 50 mg/L. Although none of the samples reached

acute toxicity levels (2000 mg/L or 14 mg/kg/day), the potential

chronic effects of low-dose methanol exposure, particularly among

heavy consumers, remain a significant concern. Moreover, major

labeling deficiencies, including inaccurate alcohol declarations

and missing batch numbers, highlight critical gaps in product

traceability and regulatory oversight. In the absence of national

standards, urgent governmental action is required to establish

methanol limits aligned with international guidelines, enforce

strict labeling practices, and implement systematic quality controls.

Future studies should expand sampling, particularly for locally

produced traditional beverages, to better characterize risks and

support the development of comprehensive public health policies.