Journal of Food Processing & Beverages

Download PDF

Research Article

Study on the Development and Stability of Passion Fruit-Pitaya Compound Beverage

Mei-ling Tang1,2, Wei-wen Duan1, Zhen-hua Duan1,2*, Yan Chen1,2, Qiu-xia Duan1,2, Yu-yan Pan1

1School of Food and Bioengineering, Hezhou University, China

2School of Food Science and Technology, Dalian Polytechnic University, China

*Address for Correspondence: Zhen-hua Duan, School of Food and Bioengineering, Hezhou University, Hezhou 542899, China, Email: dzh65@126.com

Submission: 13-January, 2020;

Accepted: 18-February 2020;

Published: 21- February 2020

Copyright: © 2020 Mei-ling Tang , et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited

Abstract

In the test, the main raw materials were whole passion fruit and

pitaya, and sugar, black fungus and stabilizers were used as the

supplementary material. The basic formulation of passion fruit-pitaya

compound beverage was studied by single factor and orthogonal

test, and its stability was discussed on this basis. The results showed

that the compound ratio of passion fruit and pitaya was 1:1(g/g), the

ratio of material to liquid was 1:3(g/g), the additive amount of sugar

was 9%, the additive amount of black fungus powder was 0.35%, and

the compound beverage had the optimal sensory effect. When 0.06%

pectin and 0.04% xanthan gum were added, the stability of compound

beverage was the optimal. The prepared compound beverage from

the formulation was suitable for acidity and sweetness, rich nutrition

and good stability.

Keywords

Passion fruit; Pitaya; Compound beverage; Stability

Introduction

With the increasing demand of people for nutrition and health, beverage has gradually developed from single to diversified and nutritious. Therefore, the fruit and vegetable juice compound beverage is favored by more and more consumers. It can achieve functional complementarily by mixing and blending the raw

materials of different nutrients and functional components [1,2]. Passion fruit (Passiflora edulis Sims) contains carotenoids, free amino acids and rich calcium, phosphorus, iron and other substances [3]. At the same time, passion fruit also has a unique fruit flavor, which is very suitable for processing fruit juices and beverages with other fruit and vegetable juices to effectively improve the flavor [4]. Pitaya (Hylocereus undatus) is rich in vitamins, dietary fiber, carbohydrates and minerals [5], and it is a tropical fruit with high dietary fiber, lowfat, low-sugar, high moisture and rich in micronutrients [6]. Black fungus (Auricularia auricular), as a medicinal and edible health food [7], has health and pharmacological effects such as lowering blood sugar, lowering blood lipids, antithrombotic and improving body immunity [8]. It is mainly based on direct sales after drying, and its product development is still in an exploratory stage.

As the dominant agricultural product resources in Guangxi, passion fruit and pitaya have the characteristics of high yield but not easy storage. They are mainly fresh fruit sales, and the processing and utilization degree is low. Therefore, it is extremely important to develop new types of processed products with market prospects. At present, there are some studies on the development of single fruit juice beverage and compound beverage from passion fruit and pitaya. For example, passion fruit and pomelo, pineapple, cucumber, etc. are respectively made into compound beverages [9-11]; pitaya and green tea, cherry tomatoes, apples, etc. are respectively developed into compound beverages [12-14]. However, it has not been reported in the current study that using the whole passion fruit and pitaya as the main raw materials to develop the compound beverage. At the same time, the phenomenon of stratification and precipitation is common in the compound beverage, and the stability of compound beverage can be effectively solved by selecting appropriate stabilizer.

The study has developed a kind of passion fruit-pitaya compound beverage, which is rich in nutritional ingredients, good taste and strong aromas of passion fruit and pitaya. It is based on whole passion fruit and pitaya as the main raw materials, and the black fungus, sugar and stabilizers as the supplementary material to study the production process and stability of compound beverage after reasonable blending in a certain proportion. It fully combines the nutrition elements of the three fruits and vegetables and the strong aroma of fruits, so that the advantages of each raw material are complementary. Therefore, the compound beverage can give full play to the strong aroma of passion fruit, the bright color of pitaya and the nutrition and health functions of black fungus. The development of passion fruit-pitaya compound beverage can not only enrich the products of fruit and vegetable juice compound beverage, but also increase the additive value of raw materials. It also explores a new way for the deep processing and utilization of passion fruit, pitaya and black fungus.

Materials and Methods

Materials:

Passion fruit and pitaya were purchased from Taihe Fruit Store

in Hezhou, Guangxi; Sugar and salt were purchased from Baijiafu

Supermarket in Hezhou, Guangxi; Selenium-rich black fungus was

produced by Zhaoping Tianrun Xianhui Edible Fungus Co., Ltd. in

Hezhou, Guangxi; Pectinase was purchased from Nuo Weixin Co,

Ltd.; Sodium hydroxide was purchased from analytical grade Xilong

Science Co, Ltd.; Phenolphthalein and ethanol were purchased from

Guangdong Guanghua Technology Co, Ltd.; Pectin, xanthan gum,

carrageenan, and guar gum were all food grade, which was purchased

from Zhejiang Duowei Chemical Food Co, Ltd.XP07-type wall-breaking cooking machine was purchase form

Foshan Shunde Xilai Home Appliance Co, Ltd.; JJ1000 electronic

balance was bought from Changshu Shuangjie Testing Instrument

Factory; PTX-FA110S electronic balance was bought from Fuzhou

Huazhi Scientific Instrument Co, Ltd.; HH-S2 Digital thermostatic

water bath was bought from Jiangsu Jinyi Instrument Technology

Co, Ltd.; DH411C air supply constant temperature oven was

purchase from Yamato Japan; Multi-function induction cooker was

purchase from Guangdong Midea Life Electric Manufacturing Co,

Ltd.; DFY-600 swing high-speed universal grinder was purchase

from Wenling Linda Machinery Co, Ltd.; JM-L50A colloid mill was

purchase from Hangzhou Huihe Machinery Equipment Co, Ltd.;

AS-Z0L vacuum packaging machine was purchase from Quanzhou

Ansen Electromechanical Co, Ltd.; 722 visible spectrophotometer

was purchase from Youke Instrumentation Co, Ltd; FE28 pH meter

was purchase from Mettler-Toledo Instruments (Shanghai) Co,

Ltd.; LH-B55 digital display sugar meter was purchase from Lu

Heng Biological Co, Ltd.; NDJ-8S digital display viscometer was

purchase from Bangxi Instrument Technology (Shanghai) Co, Ltd.;

L550 desktop low-speed large-capacity centrifuge was purchase from

Hunan Xiangyi Laboratory Instrument Development Co., Ltd.

Passion Fruit – Pitaya Compound Beverage Processing:

Passion fruit juice, pitaya juice, black fungus powder→Mixing and

allocating(Adding white granulated sugar and stabilizer)→Colloid

mill→Bagging→Exhausting→Sealing→Sterilizing→Cooling→End

product→Determination of indexes.Operation point:

Preparation of passion fruit juice: Passion fruit was selected according to the criteria of freshness, no pests, equal maturity, intact pericarp and uniform size. The selected passion fruit was cleaned, and then cut into pieces after draining the water. The sliced passion fruit was processed in a beater for 3 to 5 minutes to obtain its serous fluid. 0.004% (V/V) pectinase (enzyme activity: 10000U/g) was added to the serous fluid for enzymolysis under the condition of 20 minutes in 40 constant temperature water bath. The serous fluid was filtered with eight layers of gauze after cooling.Preparation of pitaya juice: The selection of pitaya is based on the

standard of freshness, equal maturity and uniform size. After washing

and peeling, the flesh was soaked in 0.1% brine for 3-5 minutes, and

then placed in a beater for 3-5 minutes. The serous fluid was filtered

through 8 layers of gauze.

Preparation of black fungus powder: The dried black fungus was soaked in water, and the impurities were removedafter absorbing water. The cleaned black fungus was soaked in water for 1 h, and then precooked in boiling water for 5 min. The precooked black fungus was dried in an oven, and the black fungus powder was obtained by using a grinder after drying.

Preparation of passion fruit-pitaya compound beverage: After mixing passion fruit juice and pitaya juice at a certain ratio, a certain amount of black fungus powder, sugar and stabilizer were added as supplementary material. Then the mixed fruit and vegetable juice was

processed in a colloid mill for 7 minutes. After processing, it was filled into a PET / PE compound vacuum food packaging bag, and sealed by vacuum packaging machine. The packed compound beverage was

sterilized in a water bath at 85±2 for 15min [15].

Basic Formulation Test of Compound Beverage:

Based on the pre-experiment, the ratio of sugar to acid and sensory

score were used as evaluation indexes, and the statistical analysis

adopted a multi-index weighted comprehensive score method [16].

The single factor test was performed with the compound mass ratio

of passion fruit and pitaya (3:1,2:1,1:1, 1:2, 1:3), the mass ratio of

material to liquid (1:1, 1:2, 1:3, 1:4, 1:5), the additive amount of sugar

(4%, 6%, 8%, 10%, 12%) and the additive amount of black fungus

powder (0.05%, 0.65%, 1.25%, 1.85%, 2.45%). On the basis of the

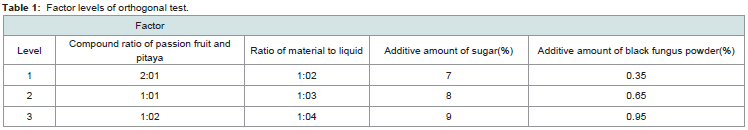

single factor test, three appropriate levels of each factor were selected

for the L9 (34) orthogonal optimization test. The levels of each factor

were shown in (Table 1).Stability Test of Compound Beverage:

Selection of single stabilizer: Under the optimal basic formulation

condition of passion fruit-pitaya compound beverage, the additive

amount of each stabilizer was fixed at 0.1%. Pectin, xanthan gum,

carrageen an and guar gum were selected as stabilizers, and stability

factor and viscosity were used as indexes. The stability of compound

beverage was studied with sensory effects.Determination of compound stabilizer and total addition: It was

difficult to achieve a good stabilization effect with a single stabilizer.

Therefore, it was considered to apply different stabilizers to compound

beverages. The use of compound stabilizers could not only enhance

system stability, but also reduce costs and improve beverage taste and

flavor. Fixed compound stabilizer with a mass ratio of 1:1, and then

compound test of three single stabilizers was performed. The test used

the stability factor and viscosity as indexes. The effects of compound

stabilizers and total additions on the stability of compound beverage

were investigated. By investigating the impact of the combination of

compound stabilizer (pectin + xanthan gum, pectin + carrageean,

xanthan gum + carrageean) and total additive amount (0.05%, 0.1%,

0.15%, 0.2%, 0.25%) on stable effect, the optimal combination of

compound stabilizer and total additive amount were determined in

combination with sensory effect.

Optimal ratio of compound stabilizer: The total addition of pectin

and xanthan gum was fixed at 0.1%, and the ratio of compound

stabilizer was 5:0, 4: 1, 3:2, 1:1, 2:3, 1:4, 0:5. The stability factor and

viscosity were taken as indexes, and the optimal ratio of compound

stabilizers were determined in combination with sensory effect.

Determination of Indexes:

The calculation of the ratio of sugar to acid: The ratio of sugar to acid of compound beverage was expressed as the brix divided by the acidity [17]. The brix was measured with a digital sugar meter. The acidity was a value measured with reference to the acid-base titration method in the national standard GB / T 12456-2008.Multi-index weighted comprehensive scoring: The contribution of each index to beverage quality was different [18], the weight factors of the ratio of sugar to acid ratio (Y1) and sensory score (Y2) were set to 0.4 and 0.6, respectively.

Comprehensive score = (the ratio of sugar to acid / (the highest ratio of sugar to acid) × 0.4 + (sensory score / highest sensory score) × 0.6.

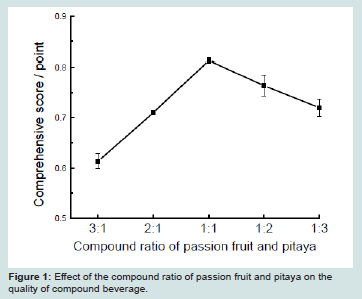

Figure 1: Effect of the compound ratio of passion fruit and pitaya on the quality of compound beverage.

Determination of the stability factor 5 mL of the prepared compound beverage (shaking thoroughly) was placed in a 50 mL volumetric flask, and the volume was adjusted with distilled water.

After shaking, the spectrophotometer was used to measure the absorbance A1 at its maximum absorption wavelength of 530 nm. Then, 10 mL of the prepared compound beverage was put into the high-speed centrifugal machine, which was centrifuged at 2000 r/min for 10 min. After taking the centrifugal machine, 5 mL of the supernatant was diluted 10 times in the same way, and the absorbance A2 was measured at the maximum absorption wavelength by shaking. The stability factor R of compound beverage was calculated [19]. The larger R indicated the more stable of compound beverage. The calculation formula was as follows:

R = A2/A1

In the formula:

R is the stability factor

A1 is the absorbance of the compound beverage before

centrifugation

A2 is the absorbance of the supernatant of the compound beverage

after centrifugation

Determination of viscosity: The viscosity of passion fruit-pitaya compound beverage system was measured at room temperature by

the NDJ-8S digital display viscometer, and the viscosity unit was milliPascals • seconds (mPa • s).

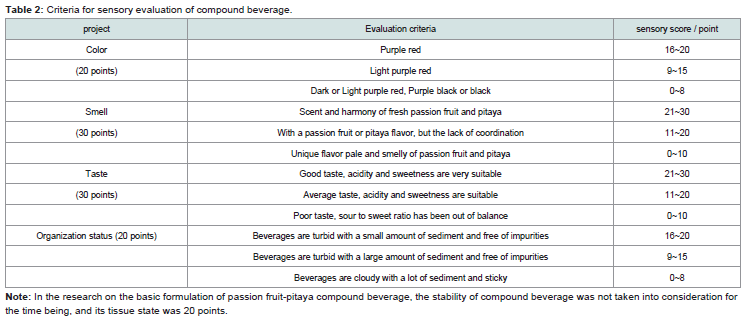

The method of sensory evaluation According to the sensory

requirements of compound beverage related standard NY/T 434-

2016, some modifications were made by referring to methods such

as De-zhi Wu [20]. The sensory evaluation group consists of 10

members of food profession, and the score is 100 points. The criteria

for sensory evaluation were shown in (Table 2).

Results and Analysis

The Compound Ratio of Passion Fruit and Pitaya:

In the color of compound beverage gradually changes from light purple to dark purple under different compounding ratios of passion fruit and pitaya, the flavor of raw materials changes from a single passion fruit flavor to a coordinated compound fruit flavor. When the compound ratio of passion fruit and pitaya was 1: 1 (g/g), the comprehensive score was the highest. The compound mass ratio of passion fruit and pitaya was 3: 1, 2: 1, 1: 2, 1: 3, the compound beverage had varying degrees of poor color and flavor. Therefore, 1: 1 (g/g) was selected as the compound ratio of passion fruit and pitaya for subsequent experiments (Figure 1).The Ratio of Material to Liquid:

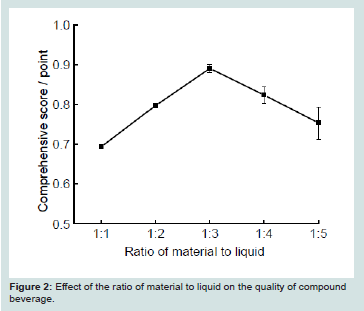

Showed that with the increase of the ratio of material to liquid, the color of compound beverage gradually changed from dark purple red to mauve red. The fruit flavor of raw materials changed from strong to light. Because of the increase of the ratio of water in the compound beverage system, the ratio of raw materials in the system was decreased, which affected the comprehensive score of compound beverage. When the ratio of material to liquid was 1:3(g/g), the color of compound beverage was purple red and the comprehensive score was high. When the mass ratio of material to liquid was 1:4, 1:5, the color of compound beverage was light purple red, the fruit flavor was light, the taste was poor and the comprehensive score was low. Therefore, 1: 3 (g/g) was selected as the ratio of material to liquid for

subsequent experiments (Figure 2).

Figure 5: Effect of different stabilizers on the stability factor and viscosity of compound beverage.

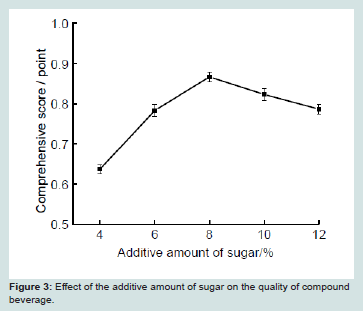

The Additive Amount of Sugar:

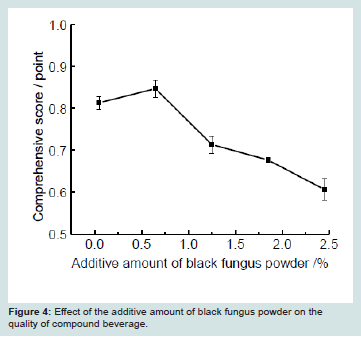

The sugar content had a small effect on the color and flavor of compound beverage, and the effect of taste was greater [21]. It can be seen from (Figure 3) that with the increase of the additive amount of sugar, the taste of compound beverage changed from sour to sweet. When the sugar was 8%, the compound beverage had a higher comprehensive score; the additive amount of sugar was 4% and 12%, the comprehensive score was low, and the imbalance of the ratio of sugar to acid. Therefore, 8% was selected as the additive amount of sugar in subsequent tests (Figure 3).The Additive Amount of Black Fungus Powder:

In The taste of compound beverage gradually had become worse with the increase of the additive amount of black fungus powder. When the additive amount of black fungus powder was 0.65%, the comprehensive score was the highest. The additive amount of black fungus powder was 1.85% and 2.45%, the color of compound beverage changed to black, the taste was not good and sticky with a strong black fungus taste. Therefore, 0.65% was selected as the additive amount of black fungus powder for subsequent tests (Figure 4)

Figure 6: Effect of different stabilizers on the stability factor and viscosity of compound beverage.

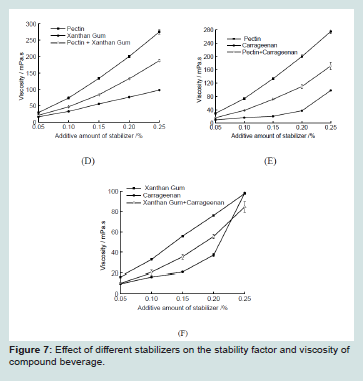

Figure 7: Effect of different stabilizers on the stability factor and viscosity of compound beverage.

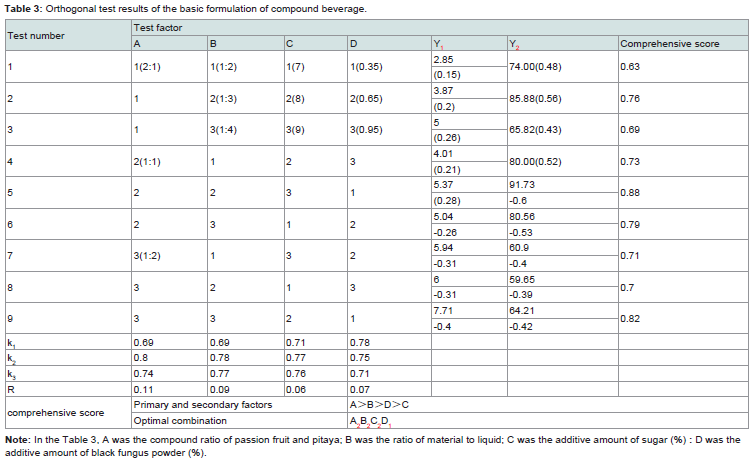

Orthogonal Optimization Test Results:

According to the results of single factor test, the influencing

factors of compound beverage were determined. Orthogonal test was

carried out to optimize the basic formulation of compound beverage.

The results were shown in (Table 3).It can be seen from (Table 3) that the compound ratio of passion

fruit and pitaya fruit, the ratio of material to liquid, the additive

amount of sugar and the additive amount of black fungus powder

all had different effects on the quality of compound beverage. In the

orthogonal test, the combination with the highest comprehensive

score was A2B2C3D1, which was 0.88. From the range R in (Table 3), it

can be seen that factor A (compound ratio of passion fruit and pitaya)

had the greatest influence on R, followed by factor B (ratio of material

to liquid) and factor D (additive amount of black fungus powder),

while factor C (additive amount of sugar) had little influence.

Therefore, the influence order of each factor was A> B> D> C, that is,

the compound ratio of passion fruit and pitaya > the ratio of material

to liquid > the additive amount of black fungus powder > the additive

amount of sugar.

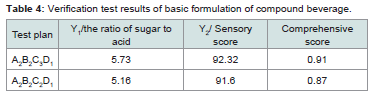

Verification Test Results:

According to the value of k in the optimal combination obtained by range analysis was A2B2C2D1, that is, the compound ratio of passion fruit and pitaya was 1:1, the ratio of material to liquid was 1:3, the additive amount of sugar was 8% and the additive amount of black fungus powder was 0.35%. Since the combination did not

appear in the orthogonal test number, the verification test was carried

out. The results were shown in (Table 4).According to the highest comprehensive score was 0.91, which was A2B2C3D1. Therefore, the optimal basic formulation combination of passion fruit-pitaya compound beverage was A2B2C3D1, that is,

the compound ratio of passion fruit and pitaya was 1:1, the ratio of

material to liquid was 1:3, the additive amount of sugar was 9% and

the additive amount of black fungus powder was 0.35%.

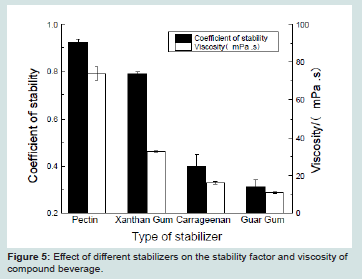

Screening Single Stabilizer:

Showed that the additive amount of four stabilizers was 0.1%, the stability of compound beverage could be improved, among which pectin was the best stability. The stability factor and viscosity of four stabilizers were: pectin > xanthan gum > carrageenan > guar gum. Therefore, three kinds of stabilizers with relatively high stability factor were selected to be mixed in pairs, which were pectin, xanthan gum and carrageenan (Figure 5.Determination of Compound Stabilizer and Total Addition:

According to (Fig 6A) and (Fig 7D), when the pectin content was 0.1%, the stability factor increases to 0.923, but the taste of compound beverage was relatively viscous and the fluidity was poor. The additive of pectin and xanthan gum was 0.1%, the stability factor was 0.85, and the compound beverage had appropriate viscosity and certain fluidity. From (Fig 6B) and (Fig 7E), when the compounded amount of pectin and carrageenan was 0.15%, the stability factor was 0.77, the viscosity was as high as 71.62 mPa • s, and the viscosity was large and the stability effect was general. When xanthan gum and carrageenan were added in an amount of 0.25%, the stability factor was only 0.759 and the viscosity was 84.55 mPa • s. When the additive amount was below 0.1%, the compound beverage with carrageenan, pectin and carrageenan, xanthan gum and carrageenan had different stratification phenomenon after 7 days. It may be that carrageenan was prone to acid catalyzed hydrolysis in acidic solutions, especially in solutions with pH4.0, the gel strength and viscosity will decrease [22] (Figure 6).In conclusion, the combination of three stabilizers could not only improve the stability of compound beverage certain extent, but also reduce the amount of single stabilizer and the viscosity of the compound beverage system. Among them, the combination of pectin and xanthan gum had the optimal stability effect, followed by pectin and carrageenan. It may be that pectin was a negatively charged polysaccharide, which could be electrostatically polymerized with protein and play a stable role by wrapping the protein under

certain conditions. Xanthan gum had very strong hydrophilicity [23]. It could absorb positively charged protein molecules under acidic conditions, and reduce protein precipitation by forming steric hindrance. At the same time, xanthan gum was very suitable for compounding with other stabilizers, which had a good synergistic interaction [24]. Considering comprehensively, 0.1% of pectin and xanthan gum was selected as the stabilizer combination of passion fruit and pitaya compound beverage (Figure 7).

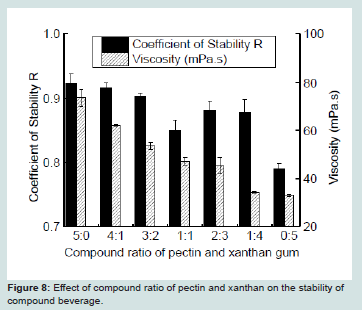

Determination of the Optimal Ratio of Compound Stabilizer:

Showed that when the total addition was fixed at 0.1%, the compound ratio of pectin and xanthan gum had different effects

on the stability factor and viscosity of compound beverage. When

the compound ratio of pectin and xanthan gum was 5: 0 and 3: 2,

the stability factors were 0.92 and 0.902 in the compound beverage

system, and the viscosities were 73.72 mPa • s and 53.58 mPa • s.

It showed that two different compounding ratios had little effect on

the stability of the system, but the viscosity of the two systems was

quite different. When the compound ratio of pectin and xanthan gum

was 0:5, the stability factor of compound beverage system was only

0.79. Considering the stability and taste of compound beverage, it was

determined that the compound ratio of pectin and xanthan gum was

3: 2, and the total addition amount was 0.1%. The passion fruit-pitaya

compound beverage had a high stability factor and a suitable viscosity

under this condition (Figure 8).Conclusion

In the test, the main raw materials were whole passion fruit and pitaya, sugar, black fungus powder and stabilizers were used as the supplementary material. The basic formulation of passion fruit-pitaya compound beverage was as follows: The compound ratio of passion fruit and pitaya was 1: 1, The material-liquid ratio was 1: 3, the additive amount of sugar was 9%, the additive amount of black fungus powder

was 0.35%; the amount of stabilizer was 0.06% pectin, and 0.04% xanthan gum. Under the condition of this process, the product had good sensory effect, and the system was uniform and stable. It was a kind of compound beverage with rich nutrition and unique flavor. Its quality indexes meet the relevant national standards.

Acknowledgement

The author would like to thank Professor Zhen-hua Duan for guiding this paper. This project was supported by the Guangxi Special Fruits & Vegetables Deep Processing and Fresh Technology Research (No .: YS201601), “Fruit-and-Vegetable Deep-processing and Fresh-keeping Team Building” project of Hezhou University (No .: YS201602) , Special Fund for Special Experts of Guangxi (No .: Hall Office [2016] 21) , Science and Technology Base and Talent Project of Guangxi (No .: Guike AD17195088) and Project Commissioned by Hainan Tianhong Yihua Technology Co., Ltd. (No .: HX-2018-035).