Journal of Environmental Studies

Download PDF

Research Article

Prediction of the Fate of Spent Engine Oil Spill from a Base Transceiver Station in the Unsaturated Zone

Theophilus N1*, Akaranta O2 and Ugwoha E3

1Centre for Occupational Health Safety and Environment, University of Port Harcourt, Nigeria

2Department of Pure and Industrial Chemistry, Faculty of Science, University of Port Harcourt, Nigeria

3Department of Civil & Environmental Engineering, Faculty of Engineering, University of Port Harcourt, Nigeria

*Address for Correspondence: Theophilus N, Centre for Occupational Health Safety and Environment, University of Port Harcourt, Nigeria, E-mail: titotheo@gmail.com

Submission: 07 May, 2020;

Accepted: 12 June, 2020;

Published: 16 June, 2020

Copyright: © 2020 Theophilus N et al. This is an open access article

distributed under the Creative Commons Attribution License, which

permits unrestricted use, distribution, and reproduction in any medium,

provided the original work is properly cited.

Abstract

In this study, Response Surface Methodology (RSM) was employed

to predict the amount of spent engine oil leached/retained in the soil

after spilling from generators in a telecommunication base station.

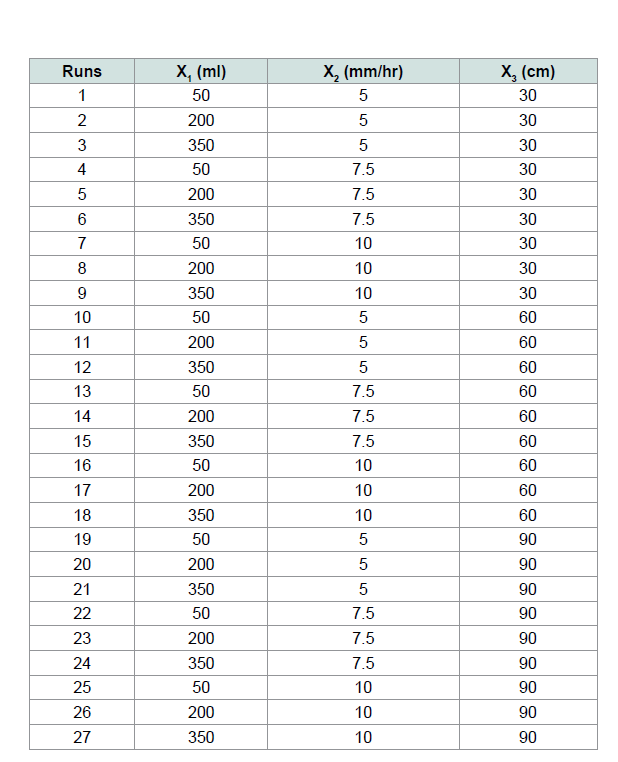

The experiment was performed at 27 runs based on RSM design

with three independent variables, i.e., soil depth, rainfall intensity

and contaminant volume. The ANOVA results show that at the 95%

confi dence level, the interactions of contaminant volume with soil

depth and rainfall intensity signifi cantly affect the amount of spent

engine oil leached/retained. Additionally, a second-order polynomial

equation was developed to relate the leached/retained used oil

and the independent variables. An optimization carried out showed

that the contaminant volume decreases with the amount of spent oil

leached. At 50 ml contaminant volume, the amount of oil leached

gave 2675.55 mg/l while soil depth is 90cm at a rainfall intensity of

5mm/hr, while 9033.68% of oil is retained in the soil. Minimizing the

amount of spent engine oil retained at 4550.4%, the contaminant

volume is given as 50ml, and soil depth shows 53.5cm while 7092.1mg/l

was leached. The model was validated by comparing experimental

data and predicted values, which showed a good agreement as well

as %error computation. The fi tted model shows a good agreement

between predicted and experimental data at R2 of 0.9587 and 0.9849

for used oil leached/retained. The analysis shows there is a good

relationship between the actual and predicted lached and retained

concentrations producing a line of best fi t with high correlation

coeffi cient and predictive relevance. This implies that the developed

model can adequately predict the transport of spent engine oil in the

unsaturated zone.

Keywords

RSM optimization; Spent engine oil; BTS; Leached; Retained

Introduction

Th e use of Diesel Generators (DGs) in powering

telecommunication Base Transceiver Stations (BTS) has its drawbacks

when compared to alternative energy, which includes but not limited

to diesel and oil spillage especially during maintenance cycles [1].

Th e process of utilizing these products associated with human

mismanagement leads to a spill of these products in the environment

in and around many BTS sites. Unfortunately, most of the BTS sites

are close to human habitation/infrastructure. Th ese products tend

to impact negatively on the surroundings aff ecting water, soil and

atmospheric air [2]. Th e increasing litigation by individuals and

sealing of some BTS sites by the regulator (National environmental

standards regulations and enforcement agency, NESREA) over the

indiscriminate disposition of diesel and waste engine oil by Telecom

BTS sites operators is a major cause of concern to the Telecoms

operators and infrastructure providers today. However, the use of

diesel and engine oil for maintenance and power of DGs has been

established to impact negatively on the environment once they are mismanaged. Groundwater contamination, disease conditions,

soil deterioration, and air quality alterations are possible problems

that are likely to be associated with the mismanagement of the

products at BTS sites [3]. Th ese liquids that are generated during DG

maintenance, site diesel transportation and refueling [4], have been

proven to contain harmful and toxic compounds or substances such

as Polychlorinated Biphenyls (PCBs), benzene, arsenic, Polycyclic

Aromatic Hydrocarbons (PAHs), lead, zinc, cadmium and other

substances that adversely impact soil, groundwater and environment

[5]. To protect and ensure the sustainability of the environment, there

is a need to ascertain the impact of the leaching of spent engine oil at

these BTS sites. Th is is required as spilled petroleum products have an

adverse eff ect on the environment according to [6]. Th ere are limited

existing information on spent engine oil spill at base transceiver

stations on analysis of the impact of spent engine oil at BTS sites

on soils. Studies have shown that adverse eff ects of oil spills when

one comes in contact with it could be hemotoxic and hepatotoxic,

and could cause infertility and cancer [7]. Th e negative impact of

oil spill include pollution of air and water, loss of soil fertility, and

environmental damage of host communities [8]. Response Surface

Methodology (RSM), as a statistical analysis approach, is an effi cient

and widely used methodology to analyze the simultaneous application

of diff erent factors or treatment technologies in the oil spill process

[9,10]. However, the present study is aimed at predicting the leaching

of spent engine oil in polluted soil at base transceiver station sites.

Understanding the fate of spent oil at base transceiver station sites

will provide insight into predicting contamination risks and extent

of contamination. Th is will provide telecommunications companies

broader view and understanding into the problem, will guide their

decisions on investments in better management of energy equipment

for BTS power, and other possible decisions on environmentally

friendly alternatives.

Materials and Methods

Study area:

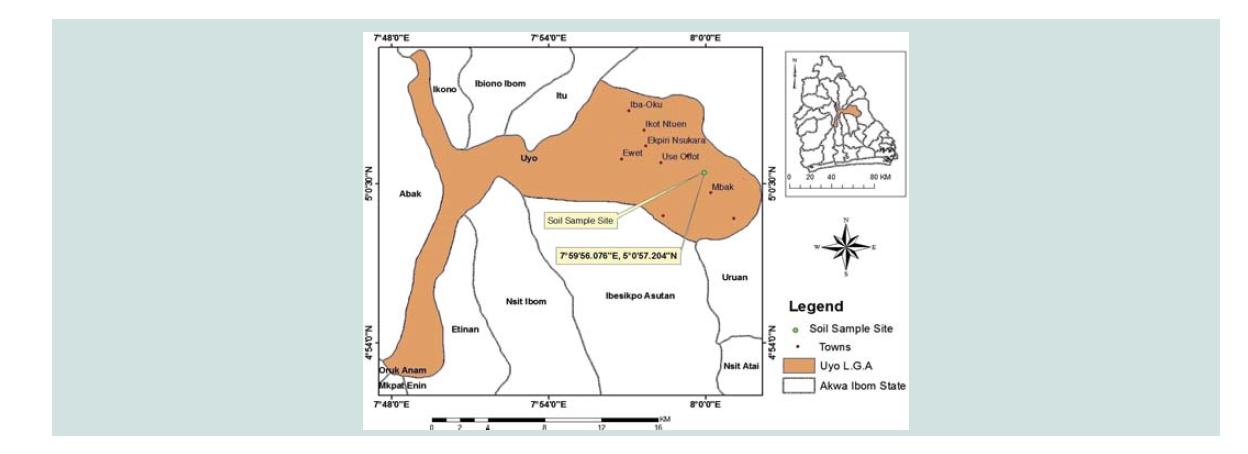

Soil samples around base transceiver station sites in Akwa-

Ibom state were collected using a fabricated auger rig. However,

the geographical coordinates of the BTS site where the inherent soil

samples were collected are between latitude 4.9057° N and longitude

7.8537° E. Th is location was selected based on the occurrence of oil

spill from diesel generators at the BTS and accessibility to the spilled

sites (see map of the BTS in Figure1).Collection of soil samples and grain size analysis:

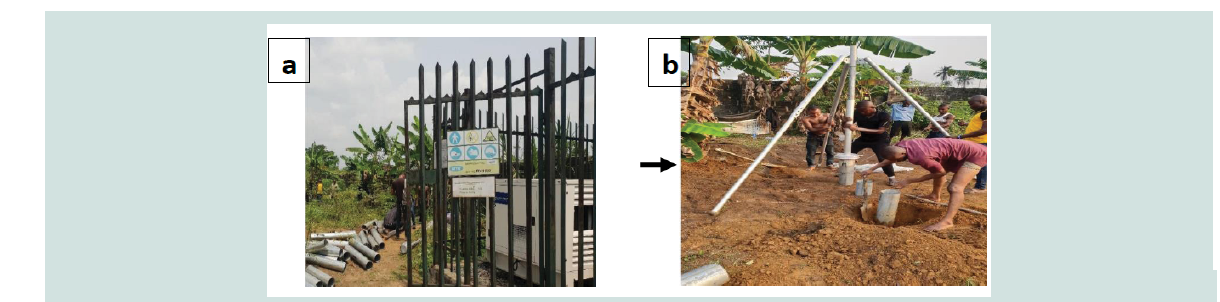

A galvanized steel mesocosm was constructed to collect soil

undisturbed. Th ree sets of 300 mm, 600 mm and 900mm height

diameter galvanized steel pipes were constructed to produce the

mesocosm used in this study. Before the collection of soil samples at

the base transceiver station sites, the topsoil was cleared to a depth of

20 cm [11]. Th e galvanized steel mesocosm, hammered with the aid

of a fabricated auger rig, was used to directly collect undisturbed soil

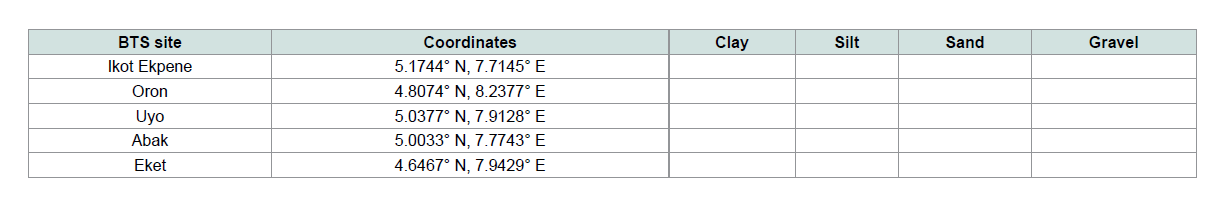

samples, as seen in (Figure 2). Five (5) samples were obtained from the study location. Th e collected soil samples were further analyzed

in the laboratory to determine the predominant soil type at the BTS

in each site where the samples were obtained. Th e soil samples were

analyzed and predominant soil types obtained utilizing grain size

analysis using the hydrometer method. Th e laboratory analysis was

carried out at the Civil and Environmental Engineering Laboratory,

University of Port Harcourt.Th e soil was characterized and classifi ed into clay, silt, sand, and gravel as shown in (Table 1).

For every randomly selected BTS within the study location, the

soil samples were extracted at various depths of 30, 60 and 90 cm, as is

consistent with the design of the experiment. For every 30 cm depth,

9 samples of undisturbed soil were collected. Similarly, for each of 60

cm and 90 cm depth, 9 samples of undisturbed soil were collected.

Th e collected soil samples were transported for contamination,

rainfall simulation and other relevant experiments.

Figure 3: Collection of spent engine oil sample during maintenance of diesel generator used at BTS site.

Figure 4: (a) Rainfall simulation set-up and (b) Contamination of undisturbed soil samples in galvanized steel mesocosms and collection of leachates.

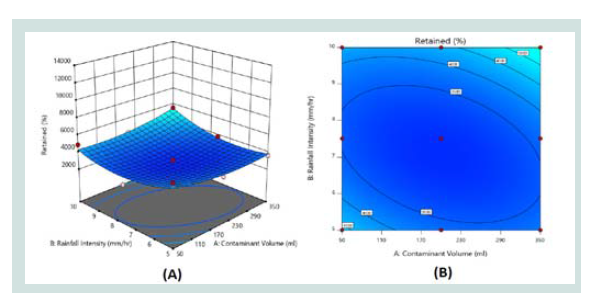

https://www.avensonline.org/fulltextarticles/wp-content/uploads/2020/11/JES-2471-4879-06-0028-fig5.png:

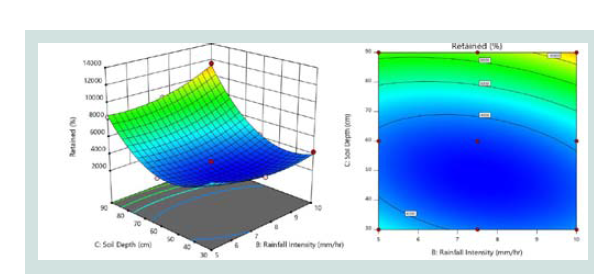

Figure 5: Eff ect of rainfall intensity and contaminant volume on leached (A) 3D surface plot (B) 2D contour plot.Design of experiment:

A 33 full factorial design of experiment was applied to investigate

the infl uence of the independent variables on leached and retained

amount of spent engine oil in the soil. Factor levels were chosen

by considering the operational limits of the experimental setup.

Response Surface Methodology (RSM) was employed in the design

of experiment. Th e experimental design was carried out in XLSTAT

2019 while the response surface analysis was computed using design

expert version 11 by stat-ease.Th e independent parameters which include the contaminant

volume, rainfall intensity and soil depth were selected using a 33

experimental design in XLSTAT 2019 soft ware. Th e selected rainfall

intensity values were chosen to replicate rainfall patterns recorded in

each of the considered sites within the study location, as was obtained

from the Nigerian Meteorological Agency (NIMET).

Collection of spent engine oil:

Th e spent engine oil was collected during the frequent maintenance

of the diesel generators used to power the Base Transceiver Station

sites (BTS). Th e spent engine oil sample was collected using plastic

bottles. Th e bottles were initially rinsed with the waste engine oil

before the actual collection as shown in (Figure 3). Th e spent engine

oil was the contaminant utilized in the experiment.Experimental set-up and procedures:

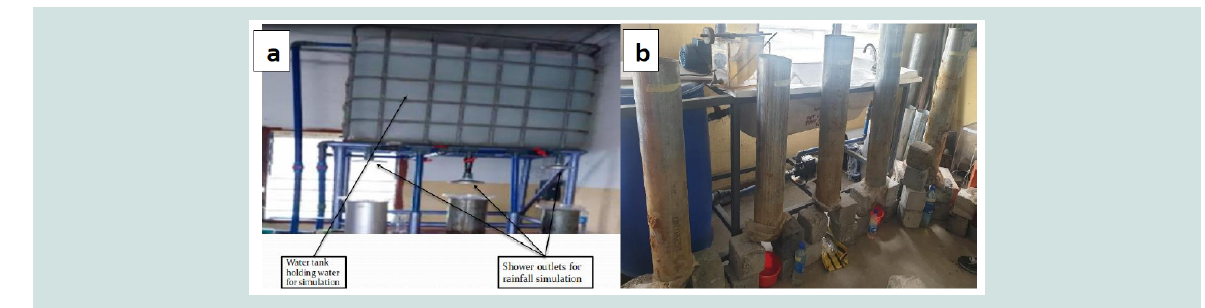

Th e experimental set-up consists of 2 major aspects (1) Rainfall

simulator set-up, and (2) Mesocosm set-up.Rainfall simulator set-up: Th e rain simulator was made of a rubber tank of 1000L capacity constructed to imitate the rainfall

pattern of the study location using the data obtained from NIMET.

Th e obtained rainfall data were used in calibrating the rainfall

simulator to produce 5 mm/hr, 7.5 mm/hr and 10 mm/hr rainfall

intensities, for diff erent volumes of the spent engine oil. Also, a 37.5

mm horsepower surface water pump was utilized for continuous

refi lling of the tank using 37.5 inches PVC pipe, in conjunction with

some plumbing fi ttings like union, valves, adaptors, pipes and elbows.

Th ree shower heads were also connected using 37.5 to 12.5 inches

reducers, 12.5 inches PVC pipes, union, valves, elbow, adaptors

and plug and cap. Th e showerheads were mounted on a 25 mm

diameter galvanized steel pipe welded to a 20 mm steel base plate

to ensure the stability of the shower headstands. Also, 3 transparent

5L plastic calibrated buckets were used to collect the water during

the simulation. Two measuring plastic cylinders (1000L and 2000L)

were used to measure the amount of rainfall. A stopwatch was used to measure the duration of rainfall when the valves were opened for

water infl ow. Simulated rainfall at various intensities (5 mm/hr, 7.5

mm/hr, 10 mm/hr) and volume of contaminants (50 ml, 200 ml,

350 ml) were introduced to the undisturbed soil in the mesocosm.

Th erefore, the intensity of the simulated rainfall was obtained as the

height of rainfall collected within a 150 mm diameter pipe per hour

of rainfall (Figure 4a).

Mesocosm set-up: Some galvanized steel mesocosms were

constructed to collect soil samples in an undisturbed condition.

Th ree sets of galvanized steel pipes of 300mm, 600mm and 900mm

diameters were constructed for use as mesocosm. Th e waste engine oil

was collected using plastic bottles during the frequent maintenance of

the diesel generators used to power the Base Transceiver Station sites

(BTS) and added separately in the diff erent containers as stated in the

experimental design and thoroughly mixed and left undisturbed for

48 hours to allow the volatilization of toxic compounds of the oil [12].

Following the rainfall simulation explained in the previous subsection.

Clips were employed to hold the mesocosms in place on a table while

being contaminated and rainfall patterns simulated. Th e 600 mm

diameter holes were constructed to install the 600 mm and 900 mm

high mesocosms that have the same diameter as the constructed hole.

Th e base of the mesocosm was protected with a net to prevent erosion

and sieve the washout with the aid of a fabricated galvanized steel

clips. Leachates were collected using plastic containers placed at the

base of the elevated steel mesocosms following the 27 experimental

runs (Figure 4b).

Determination soil hydrocarbon extraction water content:

Th is test was used to determine the weight of a wet sample along with the container for 24 hours in an oven and then determine the weight of a dry soil sample. A clean dry non-corrodible container was gotten

and the weight was determined, using a balance (with minimum

sensitivity to weight the samples to an accuracy of 0.04% of the

weight of soil taken. Th is comes to a sensitivity of 0.01 g. Th e required

quantity of a representative undisturbed soil sample was taken and

placed on the container. Th e container with wet soil was placed in

the oven with its lid removed for 24 hours maintaining a temperature

of 105oC (slightly above the boiling point of water). Th e container

containing the dry soil was then cooled in a desecrator with the lid

closed. However, the oven drying temperature of 105oC is suitable for

most of the soils.

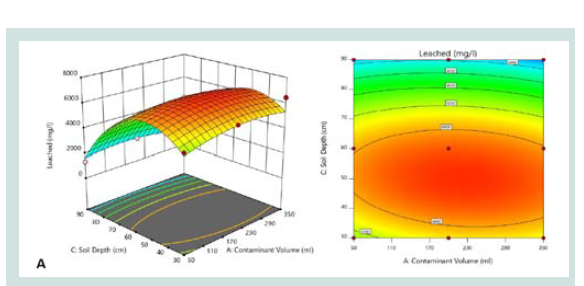

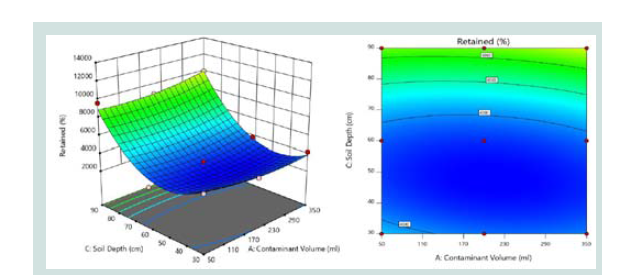

Figure 6: Eff ect of soil depth and contaminant volume on leached (A) 3D

surface plot (B) 2D contour plot.

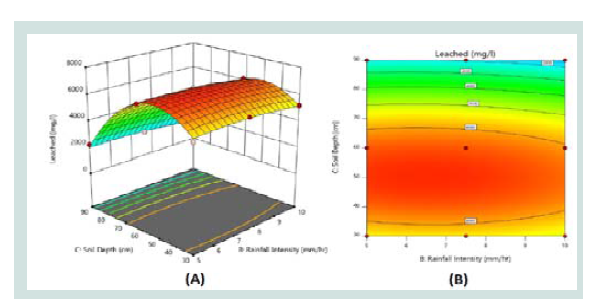

Figure 7: Eff ect of soil depth and rainfall intensity on leached (A) 3D surface

plot (B) 2D contour plot.

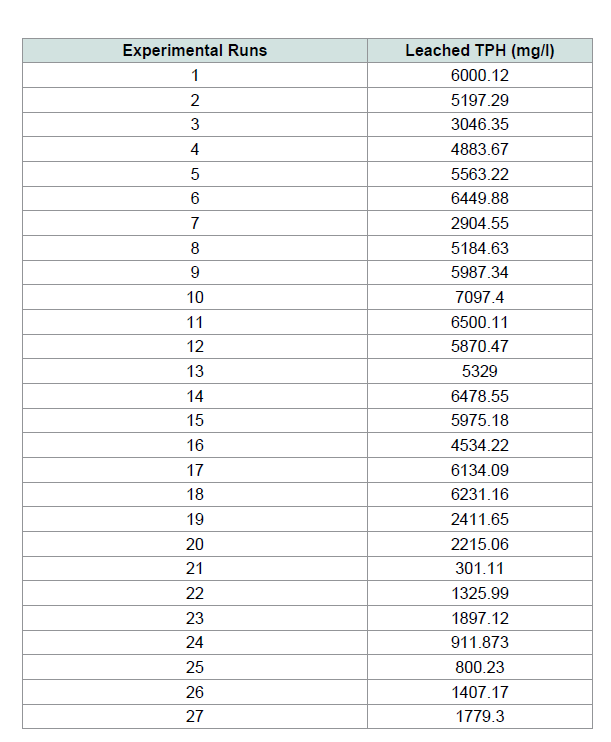

Figure 9: Eff ect of contaminant volume and rainfall intensity on retained (A)

3D surface plot (B) 2D contour plot.

Figure 10: Eff ect of contaminant volume and soil depth on retained (A) 3D

surface plot (B) 2D contour plot.

Determination of Total Petroleum Hydrocarbon (TPH): Th e TPH test was used to determine the rate of penetration of

the contaminants into the soil at BTS sites and also, the rate of

pollution of petroleum products in the at BTS sites in the study area.

Gas chromatography was used to determine the total petroleum hydrocarbon content that are in their straight chain, and also the polyaromatic

hydrocarbon content which are heavier class of hydrocarbon

starting from Benzene which have a double like chemical structure.

Results and Discussion

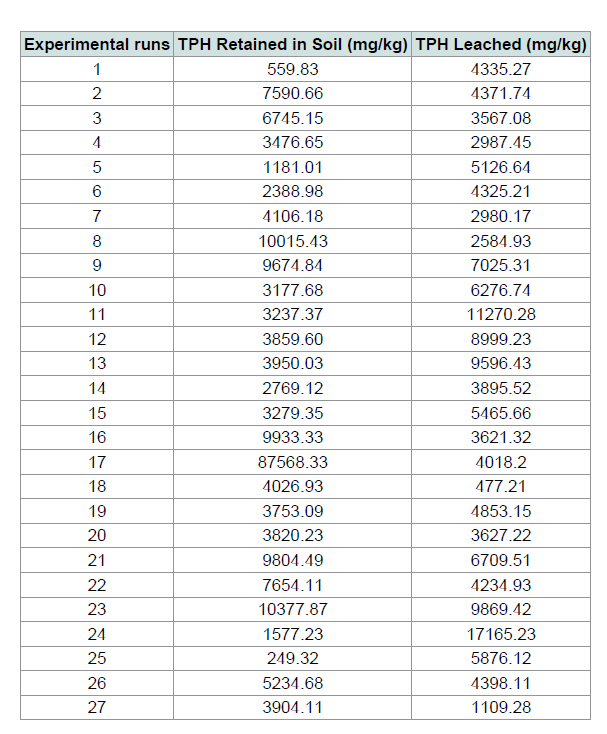

Experimental result:

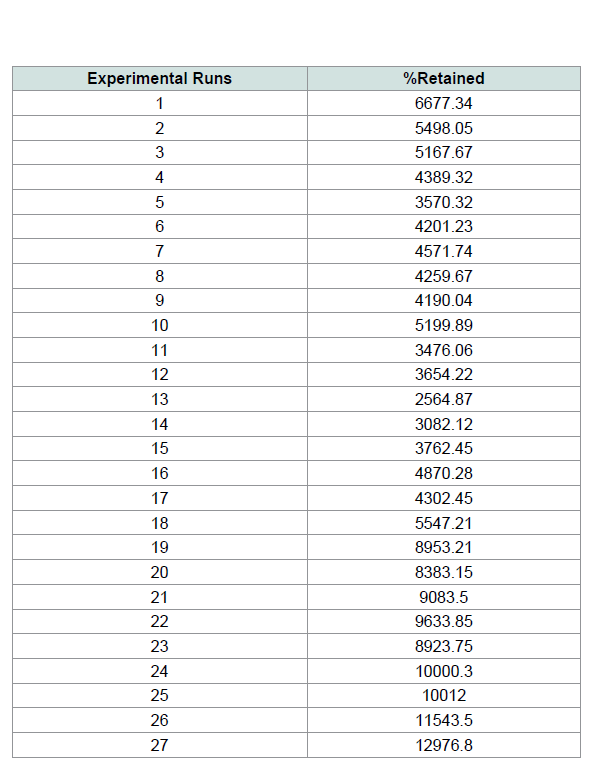

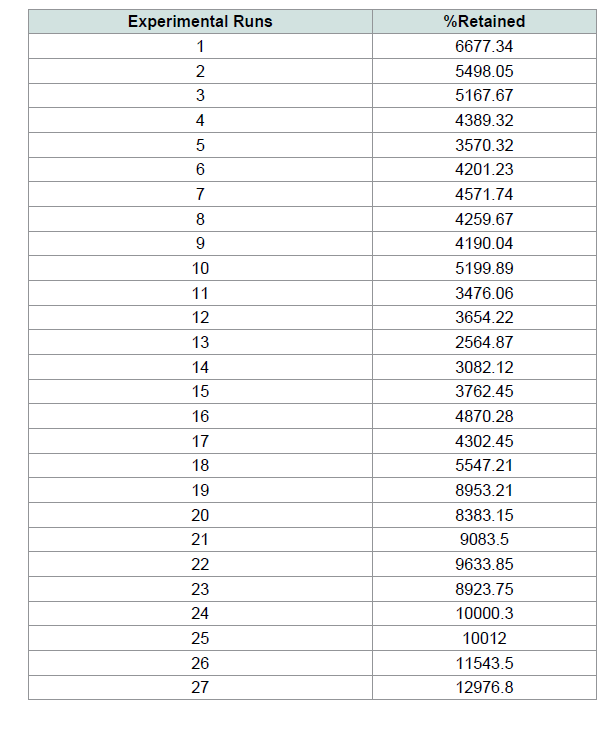

Th e experimental result for the response parameters as well as the

independent variables as shown in (Table 2), follows the 27 runs from

the experimental design.Baseline concentrations of total petroleum hydrocarbons (TPH):

Th e baseline concentration of TPH aft er 27 experimental runs at

a retention time of 20mins is shown in (Table 3).Leached TPH concentrations:

(Table 4).Relationship between leached TPH concentrations and independent variables:

Th e relationship between the TPH leached and the independent

variables has been described using second order polynomial or a

quadratic equation which predicts the leached concentration at

diff erent soil depth, rainfall intensity and the volume of contaminant

present in the soil. Th e following graphs from Figure 5-7 shows

the interaction between independent variables on the leached

TPH concentration. Th e eff ects of the factors on the response were

measured using a 3D surface plot and contour plots which indicates

the interaction between the variables. It shows the factors (soil depth

and rainfall intensity, contaminant volume) signifi cantly aff ects the response variables, leached TPH concentration.As contaminant decreases there is a corresponding decrease in

leached while rainfall intensity increases (Figure 4).

Th e factor interactions in Figure 5, as the leached increases,

contaminant volume decreases while the rainfall intensity increases.

Again, it was shown in Figure 6 that leached decreases as soil depth

increases, the contaminant volume also decreases gradually as seen

on the 3D plot.

Figure 6. It shows that as the soil depth increases the amount

of used oil leached decreases signifi cantly with a slight decrease in

rainfall intensity as shown in the 3D plot of Figure 7A. Although, the

ANOVA result showed that soil depth is the most signifi cant variable

aff ecting the leached. Th erefore, the 3D plot confi rms that soil depth

aff ected the leached signifi cantly.

Figure 6. It shows that as the soil depth increases the amount

of used oil leached decreases signifi cantly with a slight decrease in

rainfall intensity as shown in the 3D plot of Figure 7A. Although, the

ANOVA result showed that soil depth is the most signifi cant variable

aff ecting the leached. Th erefore, the 3D plot confi rms that soil depth

aff ected the leached signifi cantly.

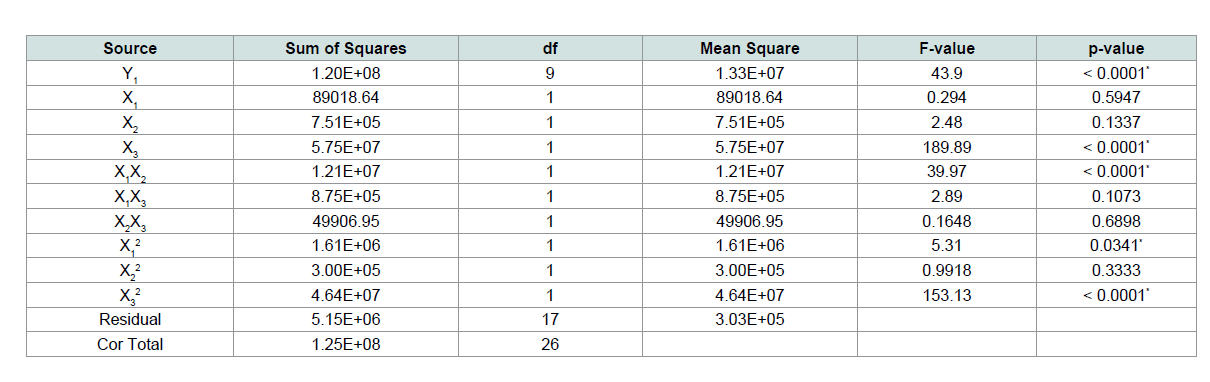

Th e model F-value of 43.90 implies the model is signifi cant. Th ere

is only a 0.01% chance that an F-value this large could occur due to

noise. P-values < 0.05 indicate model terms are signifi cant. In this case

X3, X1 X2, X12, X32 are signifi cant model terms. Values greater than

0.1000 indicate the model terms are not signifi cant (Table 5). Here,

it appears that soil depth is the most signifi cant variable aff ecting

the leached as indicated by the p-value in (Table 3). However, the coeffi cient of correlation between model and experiment shows a

strong positive relationship (R2=0.9587), this is an agreement with

the works of [13,14].

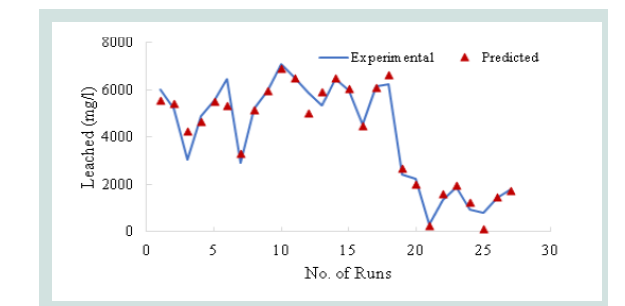

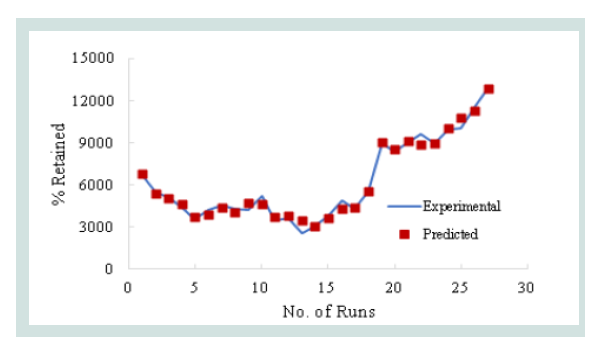

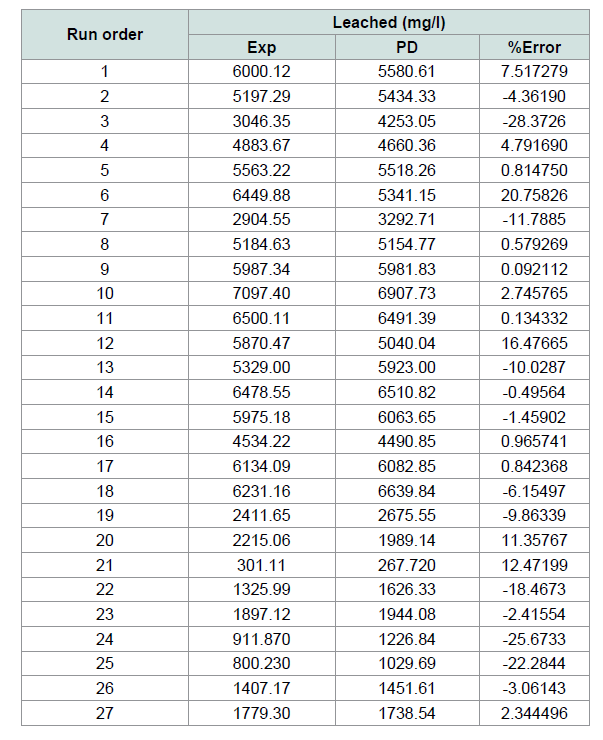

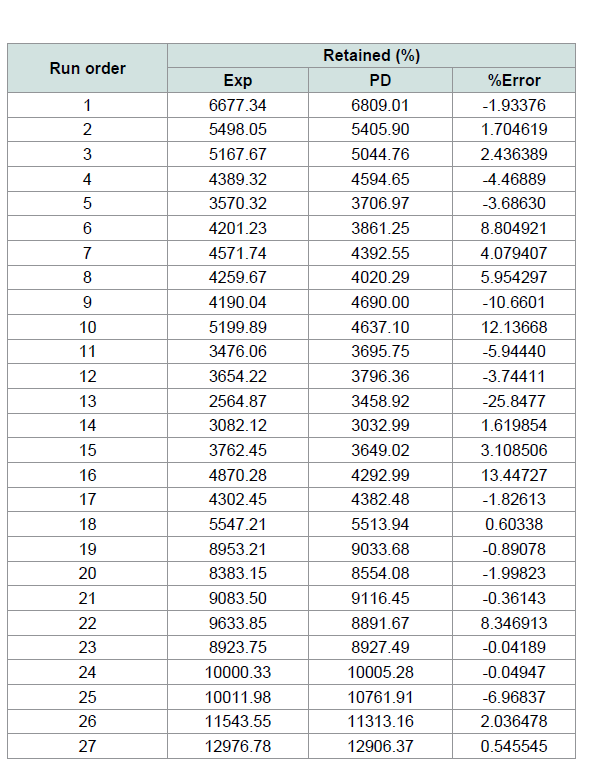

Leached TPH model validation:

Th e model was validated by comparing experimental and

predicted Vvalues, the error between model and experiment was

determined (Table 5). Th e percentage error was calculated using the

following formula:From the Table 6 above it shows that the error between predicted

and experimental values for retained and leached amount of used oil

in the soil is minimal which ranges from -28.4% to 20.8% for leached

and -25.8% to 13.4% respectively as shown in the table above.

Th e graphs in Figure 7 show that the model is valid when

compared with the experimental data for leached parameters.

Retained TPH concentrations:

(Table 7).Relationship between retained TPH concentrations and independent variables:

Th e following graphs from Figure 9-11 shows the relationship

between independent variables on the leached TPH concentration.

Th e eff ects of the factors on the response were measured using a 3D

surface plot and contour plots which indicates the interaction between

the variables. It shows the factors (soil depth and rainfall intensity, contaminant volume) signifi cantly aff ects the response variables, the

TPH concentration retained in the soil.

Figure 11: Eff ect of rainfall intensity and soil depth on retained (A) 3D surface

plot (B) 2D contour plot.

Th e 3D surface and contour plots in indicate that the eff ect of

Contaminant volume Figures 9, Rainfall intensity and Soil depth on

retained (%) and leached (mg/l). It was observed study that a lower

rate of %retained was attained with lower rainfall intensity.

In the 3D surface and contour plots in Figures 10 indicates that

the eff ect of Contaminant volume, and Soil depth on retained (%). It

was observed that a higher rate of %retained was attained with higher

soil depth. It shows that as rainfall intensity increases, the retained

also increases at lower soil depth. However, the interaction between soil depth and rainfall intensity on retained shows that, retained

increases as rainfall intensity while soil depth reduces (Figure 11).

Retained TPH model:

Th e model F-value of 123.42 implies the model is signifi cant.

Th ere is only a 0.01% chance that an F-value this large could occur

due to noise. P-values < 0.05 indicate model terms are signifi cant. In

this case X2, X3, X1X2, X1 X3, X2 X3, X12, X22, X32 are signifi cant model

terms. Values greater than 0.1000 indicate the model terms are not

signifi cant (Table 8). However, the p-values suggest that rainfall

intensity and soil depth are the most signifi cant variables aff ecting the

retained. Th e coeffi cient of correlation shows a strong and positive

relationship between the experiment and the model (R2=0.9849).Th e equation in terms of actual factors can be used to make predictions about the response for given levels of each factor.

However, these results conform with that of who used RSM to

optimize Bambara nut kernel yield with 3 factors (independent

variables) [14].

Th is work is in agreement with the report of, applied response

surface methodology to oil spill remediation.

Retained TPH model validation:

Th e model was validated by comparing experimental and

predicted values, the error between model and experiment was

determined (Table 9). Th e percentage error was calculated using the

following formula [15].Th e graphs in Figure 12 show that the model is valid when

compared with the experimental data for retained parameters.

Conclusion

In this study, three sets of galvanized steel pipes of 300mm,

600mm and 900mm diameters were constructed for use as mesocosm.

Th e waste engine oil was collected using plastic bottles during the

frequent maintenance of the diesel generators used to power the Base

Transceiver Station sites (BTS) and added separately in the diff erent

containers as stated in the experimental design and left undisturbed

for 48 hours to allow the volatilization of toxic compounds of the oil [12]. A replica lysimeter was constructed to hold the 300mm,

600mm and 900mm high mesocosms that have the same diameter

as the constructed hole. Th e base of the mesocosm was protected

with a net to prevent erosion and sieve the washout with the aid of

a fabricated galvanized steel clips. Leachates were collected using

plastic containers placed at the base of the elevated steel mesocosms

following the 27 experimental runs (Figure 4b). Th e experiment

followed a 33 full factorial design. RSM was employed to study the

infl uence of the contaminant volume, rainfall intensity and soil depth

on the amount of oil leached/retained, which showed there is a strong

and positive correlation between predicted and experimental values,

0.9587 and 0.9849 for leached and retained respectively. However,

the interaction between the diff erent independent variables and

their respective eff ects on the response was studied by analyzing

the response surface contour plots [16]. According to [17], RSM

procedure has some benefi ts like higher percentage yield, reduced

process variability, closer confi rmation for output response in target

achievement. Consequently, it was observed that several factors

such as soil depth, rainfall intensity and contaminant volume can

signifi cantly aff ect the amount of spent engine oil leached/retained in

the unsaturated zone.

Th e analysis shows there is a good relationship between the actual

and predicted lached and retained concentrations with the predicted

value clustered around the experimenttal line as depicted in Figure

8 and 12 producing a line of best fi t with high correlation coeffi cient

and predictive relevance of 0.9587 and 0.9849 respectively. This therefore implies that the developed model can adequately predict the

transport of spent engine oil in the unsaturated zone.