Journal of Food Processing & Beverages

Download PDF

Research Article

*Address for Correspondence: David Iordehiin Gbenyi, Department of Food Science and Technology, Federal Polytechnic, P.M.B. 35, Mubi, Adamawa State, Nigeria, Tel: +2348155667699; E-mail: digbenyi@yahoo.com

Citation: Gbenyi DI, Nkama I, Badau MH, Idakwo PY. Effect of Extrusion Conditions on Nutrient Status of Ready-to-Eat Breakfast Cereals from Sorghum-Cowpea Extrudates. J Food Processing & Beverages. 2016;4(2): 8.

Copyright © 2016 Gbenyi DI, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Journal of Food Processing & Beverages | ISSN: 2332-4104 | Volume: 3, Issue: 2

Submission: 01 July, 2016 | Accepted: 27 July, 2016 | Published: 01 August, 2016

Essential amino acid profile of the sorghum-cowpea extrudates

Model description and validation

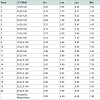

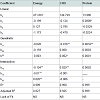

The regression coefficients for the essential amino acids of sorghum-cowpea extrudates are presented in Table 6. The lysine, threonine, methionine and isoleucine content of the extrudates were significantly (p≤0.05) influenced by the linear effect of feedcomposition. Valine and leucine were significantly affected by the quadratic effect of feed composition while methionine and valine were significantly (p≤0.01) influenced by the linear and quadratic effects of extrusion temperature. Feed composition was observed to have the most influence on the essential amino acids followed by extrusion temperature. Feed moisture had no significant (p≤0.05) effect on any of the essential amino acids. The R2 values ranged from 0.84 to 0.96 for all the essential amino acids. There was significant lack of fit in all responses however; the high values of R2 and adjusted R2 suggest that the model equation could be used to predict the essential amino acid profile of the sorghum-cowpea extrudates.

Effect of Extrusion Conditions on Nutrient Status of Ready-to-Eat Breakfast Cereals from Sorghum-Cowpea Extrudates

David Iordehiin Gbenyi1*, Iro Nkama2, MamuduHalidu Badau3 andPaul Yahaya Idakwo3

- 1Department of Food Science and Technology, Federal Polytechnic Mubi,Adamawa State, Nigeria

- 2Department of Food Science and Technology, University of Nigeria, Nsukka, Nigeria

- 3Department of Food Science and Technology, University of Maiduguri, Maiduguri, Nigeria

*Address for Correspondence: David Iordehiin Gbenyi, Department of Food Science and Technology, Federal Polytechnic, P.M.B. 35, Mubi, Adamawa State, Nigeria, Tel: +2348155667699; E-mail: digbenyi@yahoo.com

Citation: Gbenyi DI, Nkama I, Badau MH, Idakwo PY. Effect of Extrusion Conditions on Nutrient Status of Ready-to-Eat Breakfast Cereals from Sorghum-Cowpea Extrudates. J Food Processing & Beverages. 2016;4(2): 8.

Copyright © 2016 Gbenyi DI, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Journal of Food Processing & Beverages | ISSN: 2332-4104 | Volume: 3, Issue: 2

Submission: 01 July, 2016 | Accepted: 27 July, 2016 | Published: 01 August, 2016

Abstract

Sorghum and cowpea flour mixes (90:10, 80:20 and 70:30 ratios respectively) were extruded at 20%, 22.5% and 25% moisture levels and 120 °C, 140 °C and 160 °C barrel temperatures using a singlescrew extruder. A central composite face-centered design was used to study the effects of feed composition, feed moisture and extrusion temperature on the proximate composition and essential aminoacids of the extrudates. Results obtained showed that the energy, carbohydrate, protein, moisture, fat, ash and crude fibre content of the extrudates increased from 363.63 to 379.15 kcal, 70.19 to 77.55%, 13.20% to 17.80, 5.50 to 7.90%, 1.55 to 1.75% and 1.60 to 2.80% and 2.10 to 2.72% respectively. Lysine content of the extrudates increased from 5.46 to 7.27 g/100 g, while methionine ranged from 1.05 to 1.85 g/100 g. There was significant (p≤0.01) increase in the protein and amino acid contents of the extrudates due to supplementation with cowpea flour. Both the protein content and all the essential amino acids of extrudate samples were in sufficient amounts to meet the requirements for adults and children of 10 to 12 years of age. The coefficients of determination (R2) were 0.91, 0.96, 0.99, 0.87, 0.85, 0.84 and 0.99 for the energy, carbohydrate, protein, moisture, fat, ash and crude fibre content of the extrudates respectively. There was nonsignificant lack of fit. The R2 values ranged from 0.83 to 0.96 for essential amino acids. Feed composition had the most effect on the various responses followed by barrel temperature. The model equations could be used to predict the proximate composition and essential amino acid profile of the extrudates.Keywords

Extrudates; Nutrients; Breakfast cereal; Amino acids; Response surfaceIntroduction

Protein Calorie Malnutrition (PCM) is believed to be the primary nutritional problem in most developing countries of the world [1] including Nigeria. Legumes are rich sources of protein and theessential amino acid lysine, but are usually deficient in sulphurcontaining amino acids, methionine and cysteine. On the other hand, cereal grains contain lower amounts of proteins which are deficient in lysine but have sufficient amounts of sulphur containing amino acids [1]. It is therefore reasonable that legume seed grain proteins are the ideal supplement to cereal grain protein in producing an overall essential amino acid balance [3,4]. Pulses are cheaper sources of protein in developing countries, when compared to animal protein [5]. The protein in cowpea seed is rich in the amino acids, lysine and tryptophan; it is deficient in methionine and cysteine when compared to animal proteins. This is why cowpea seed is valued as a nutritional supplement to cereals and an extender of animal proteins [6].FAO reports [7] showed that Nigeria is the highest producer of cowpea with 2,920,000 tons followed by Niger with 1,100,000 tons, while Mali places third position with 100,000 tons. Cowpea yield andproduction by states in Nigeria has been reported by Nkama et al. and IITA [8,9]. The grain is valued for its flavor and short cooking time and can be used in a wide variety of ways principally as a nutritious component in human diet.

Nigeria is also the largest producer of sorghum in Africa and second largest the world over [10]. Unfortunately, sorghum is consumed largely in the rural areas where it is produced [11]. The constraint on sorghum utilization has been the lack of processed foods such as flour, meal, breads, or convenience food products foruse by the working class who cannot devote hours making flour from the raw grain. The development of a sorghum-based food processing industry would do a lot to offset Africa’s shift in demand towards imported rice and wheat [11]. Research has shown that sorghum grain can be parboiled to create a fast-cooking, convenience food, just as has been done with rice. In Botswana, sorghum meal is alreadyommercially available [11]. Several reports [12-14] have also shown that complementation could be achieved by mixing legumes and cereals, which are in sufficient supply in the tropics and Sub-Saharan Africa.

Presently, there is a challenge in the food process industry to develop convenience foods such as breakfast cereals and snacks of high nutritional value that will adequately meet the needs of the working population in developing countries using local raw materials. One such versatile and efficient technology that finds application in the production of convenience foods is extrusion cooking [15]. Extrusioncooking is preferable over other food processing methods because it is a high temperature short time (HTST) process which preserves important nutrients, denatures antinutritional components of foods (trypsin inhibitors, tannins and phytates), disinfects the final product and maintains normal colours and flavours of the food [16,17]. The main purpose of extrusion is to increase variety of foods in the diet by producing a range of products with different shapes, textures,colours, and flavours from basic ingredients [18].

The one-variable-at-a-time method of experimentation is inappropriate in many circumstances [19-21]. Response surface methodology is useful in particular situations such as extrusioncooking, where several input variables potentially influence some performance measure or quality characteristic of the process. There s considerable practical experience indicating that second-order models work well in solving problems such as encountered inextrusion cooking [22]. The objective of this work was to assess the effect of cowpea substitution, feed moisture and barrel temperatureon the proximate composition, and essential amino acids profile of sorghum-cowpea extrudates.

Materials and Methods

Procurement of raw materialsThe red sorghum variety (Chakalari red), was obtained from Maiduguri Monday market. Cowpea (var kananede) was obtained from the Mubi main market, Adamawa State, Nigeria.

Preparation of sorghum flour

About 15 kg of sorghum grains were cleaned using a laboratory aspirator (Vegvari Ferenc Type OB125, Hungary) to remove stalks, chaff, leaves and other foreign matter. They were then washed withtreated tap water in plastic basins and sun dried on mats for 2 days at 38 °C and relative humidity of 27.58%) to 12% moisture. This was then dehulled using a commercial rice dehuller (Konching 1115, China) and milled using an attrition mill (Imex GX 160, Japan).The flour was sieved to pass mesh number 25 [22] before packing in polythene bags for further use.

Preparation of cowpea flour

About 3 kg of cowpea was soaked in water for 10 min to loosen the seed coat. The kernels were then cracked in a mortar with pestle. The seed coat was washed off in excess water. The beans were ovendried (Model: Chirana HS 201A, Hungary) at 80 °C to 12% moisture content and milled into flour (Imex GX 160, Japan) which was sieved to pass mesh number 25 [23] before packing in polythene bags for further use.

Blending of sorghum flour with cowpea flour and moisture adjustment

Sorghum flour was blended with cowpea flour in varying proportions (10%, 20% and 30% cowpea flour). The total moisture content of the blends was adjusted to the desired level according to Zasypkin and Tung-Ching [24]. The blends were then mixed using aaboratory mixer and the moisture allowed to equilibrate.

Extrusion of sorghum and cowpea blends

Extrusion cooking was done in a single-screw extruder (Model: Brabender Duisburg DCE-330), equipped with a variable speed DC drive unit and strain gauge type torque meter. The extruder was fed manually through a screw operated conical hopper using a plastic bowl. The hopper which is mounted vertically above the endof the extruder is equipped with a screw rotated at variable speed. Experimental samples were collected when steady state (constant torque and temperature) was achieved. Variables considered were feed composition, feed moisture content and temperature of extrusion. Extrudates were kept on stainless steel work benches overnight to dry. They were then packaged in polythene bags prior to analysis.

Proximate composition

Moisture and crude fibre determination were carried out using the direct hot air oven method [25]. Crude fat was determined by the Soxhlet method (Egan et al.) [26]. The Micro-Kjeldahl methoddescribed by Egan et al. was used to determine the crude protein content of samples [26]. The total ash content of samples was determined by the AOAC method [25]. Total carbohydrate was determined by subtracting the known amounts of moisture, crude fat, crude protein and ash from 100. The difference was reported as the per cent carbohydrate [26]. Calorific values of the extrudates were estimated using the Atwater factors of 4 for carbohydrate and protein,and 9 for crude fat [27].

Amino acid analysis

The amino acid profile of the samples was determined using methods described by Benitez [28]. The known sample was dried to constant weight, defatted, hydrolyzed, evaporated in a rotary evaporator and loaded into the Technicion Sequential Multi-Sample Amino Acid Analyzer (TSM) (Model: DNA 0209).

Experimental design

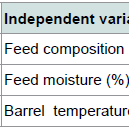

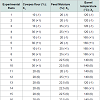

A central composite face-centered (CCFC) non-rotatable design with three independent variables: Feed composition (%), feed moisture (%) and extruder barrel temperature (°C) at three levels of -1, 0 and +1 for each variable [29,30] was used to predict the optimum processing conditions for the extrusion of the breakfast cereals (Table 1). The feed which was made up of sorghum and cowpea flours was blended in the ratios of 10, 20 and 30% cowpea to sorghum flourrespectively. Extrusion runs were performed as presented in (Table 2). The levels of the various independent variables were arrived at after preliminary extrusion runs. The Central Composite Face- Centered Design used in this work was produced using MINITAB 14 [31] statistical software. The design was made up of 8 cube points, 6 centre points in the cube and 6 axial points giving a total of 20 design points. The general second-order equation was used in the experimental design of this work thus:

Y = b0 + b1X1 + b2X2 + b3X3 + b11(X1)2 + b22(X2)2 + b33(X3)2 + b12X1X2 + b13X1X3 + b23X2X3 + e ..... (1)

where X1, X2 and X3 are feed composition, feed moisture and barrel temperature, respectively; bo is the regression constant; b1, b2 and b3 are linear regression terms; b11, b22 and b33 are quadratic regression terms; b12, b13 and b23 are the cross-product regression terms; ε is the error term.

Statistical analysis

Multiple regression analysis and analysis of variance were used to assess the adequacy of the second-order model equation in predicting the effects of the independent variables on the product responses. Numerical optimization and interactive graphs were used to obtain optimum values for the responses and the input variables [31]. MINITAB Version 14 statistical analysis software was used in the statistical analysis of data.Results and Discussion

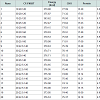

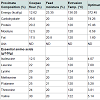

Proximate composition of sorghum-cowpea extrudatesThe proximate analysis of sorghum-cowpea extrudates is presented in Table 3. The energy (calorific) values of the extrudates varied from 370.03 to 379.15 kcal. Calorific values were estimated using the Atwater factors of 4 for carbohydrate and protein and 9 for crude fat. The carbohydrate content of the samples ranged from 71.01% to 77.99%. There was significant (p≤0.05) difference in the carbohydratecontent of the extrudates. The carbohydrate content of extrudates decreased as the amount of cowpea flour in the feed increased. Filli et al. and Danbaba et al. made similar observations when cowpea flour was supplemented with millet in the production of extruded fura and broken rice in the production of instant porridge respectively [12,32]. This could be due to the lower amount of carbohydrate in cowpea which tends to lower the overall carbohydrate content of the extrudate blends. The amount of carbohydrate is an indication of the energy stores of the food product, which is in this case adequate for both adults and children. The moisture content of the samples ranged from 5.20 to 7.70%. There was a significant (p≤0.05) difference in the moisture content of the extrudates. Moisture content is very critical to shelf-life of food products. Higher moisture levels (that is greater than 14%) would require further processing to improve shelf stability. This is explained by the higher water activity at these moisture levels [15]. The moisture levels of the extrudates in this report were within safe limits (below 14%) for storage. The protein content of the extrudates increased from 13.15% to 17.80%. There was significant (p≤0.05) increase in protein content of extrudates as the amount of cowpea flour was increased in the feed. Filli et al. and Danbaba et al. similarly reported increased protein content for millet-cowpea and rice-cowpea extrudates respectively [12,32]. Olapade and Aworh observed that blends of fonio and cowpea flours produced good complementary foods in terms of proximate composition especially protein content which increased with increased amount of cowpea in the blend [33]. The optimum protein content of the extrudates in this work was 15.46% at 20% cowpea, 20% feed moisture and barrel temperature of 120 °C. The recommended protein requirement for complementary foods to combat protein malnutrition is 15% suggesting the adequacy of protein in the products. Protein requirement is the amount of protein or its constituent amino acids, or both that must be supplied in the diet in order to satisfy the metabolic demand and achieve nitrogen equilibrium. The requirements will in most cases be greater than the metabolic demand because of the factors associated with digestion and absorption, which influence the digestibility and consequent amount of nitrogen lost in the feaces [34]. The crude fat content of the samples was very low and ranged from 1.55% to 1.75%. There was significant(p≤0.05) reduction in the crude fat content of the extrudates as the amount of cowpea flour in the feed was increased. Sorghum is richer in crude fat than cowpea thus; supplementation with cowpea may be responsible for this reduction. This is in agreement with Anuonye et al., Filli et al. and Danbaba et al. who observed similar decreases in fat content when soybean and cowpea were blended with acha, millet and rice respectively prior to extrusion on a single screw extruder [12,32,35]. This is lower than the recommended daily fat intake of 20 to 35% [36] however consumption of fat from other sources will make up for this difference. Low fat foods preserve better since they are less prone to rancidity in storage. Dietary fats are important for maintaining good health. Other than supplying energy, they carry fat soluble vitamins in the diet, are structural bodily components, and are involved in vital physiological processes, including growth, development, inflammation and brain function [37]. The ash content is an indication of the mineral content of the samples. Per cent ash for the samples ranged from 1.60 to 2.54%. There was significant (p≤0.05) variation in the ash content of the samples. This may be due to the variation in the feed composition. Minerals are generally stable since extrusion temperature and feed moisture are not expected to cause a significant change in their composition. The per cent crude fibre for the extrudates ranged from 2.10 to 2.72%. Dietary fibre includes polysaccharides, oligosaccharides, lignin, and associated plant substances. Dietary fibre promotes beneficial physiologic effects including laxation, and/or blood cholesterol attenuation, and/or blood glucose attenuation [38]. The most notable response to diets providing very low levels of fibre intake is an increase in constipation. However, several negative physiological responses occur in individuals who consume low levels of dietary fibre over time, particularly an increased risk for coronary heart disease [39]. Adults (19 to 50 years) require 38 g/day for males and 25 g/day for females. Children require less fibre, ranging from 19 g/day for 1 to 3 years to 31 g/day for 9 to 3 years [39]. The breakfast cereals in this report were low in crude fibre. This is ideal for growing children. Adults will however have to eat foods from other sources that are richer in fibre.

The essential amino acid profile of sorghum-cowpea extrudates is presented in Table 4. Lysine varied from 5.46 to 7.27 g/100 g, while methionine ranged from 1.03 to 1.85 g/100 g. There was a significant(p≤0.05) increase in lysine, methionine and all the other essential amino acids as a result of supplementation with cowpea flour. Filli et al. reported similar improvements when extruded fura was produced from millet-cowpea flour composites [32]. Lysine and methionine are the most limiting essential amino acids in legume-cereal-based products [40], which are the majority of extruded products. Lysine is however, heat labile thus, a focus on lysine retention during the extrusion process is of particular importance. Paes and Maga, Anuonye et al. and Anuonye et al. have variously reported depletion of some amino acids as a result of extrusion cooking [35,41,42]. Singh et al. however posited that mild extrusion conditions (high moisture content, low residence time, low temperature) improve the nutritional quality, while high extrusion temperature (≥200 °C), low moisture (< 15%) and/or improper formulation (e.g. presence of high-reactive sugars) can impair nutritional quality adversely [40]. In order to keep lysine losses within an acceptable range, it is necessary to avoid extrusion cooking above 180 °C at feed moisture below 15%, and/or avoid the presence of reducing sugars during the extrusion process [40]. The highest barrel temperature in this work was 160 °C, lowest feed moisture employed was 20% while the screw speed waskept constant at 200 rpm suggesting that all the extrusion conditions employed were mild enough to protect lysine and other fragile amino acids. All the essential amino acids of extrudates were in sufficient quantities [43] for children of 10 to 12 years of age. Amino acids are the building blocks of proteins. Animals cannot synthesize the amino group (NH2), so in order to obtain the amino acids necessary for protein synthesis; they must eat plants or other animals [44]. Cereals are generally believed to complement legumes in providing amino acids balance in the diet. The breakfast cereals produced in this work could be incorporated in the feeding regimes of primary and secondary schools, and internally displaced peoples’ camps (or refugee camps) to improve the nutritional status of (growing) children in Nigeria.

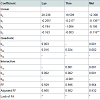

The regression coefficients for the proximate composition of sorghum-cowpea extrudates are presented in Table 5. All the responses except energy were significantly (p≤0.01) influenced by the quadratic effects of feed composition. The energy, carbohydrate, moistureand ash were significantly (p≤0.05) influenced by the interaction effects of feed composition and extrusion temperature. The protein content was significantly (p≤0.05) influenced by the linear effect of feed composition and the quadratic effect of feed composition and barrel temperature. The coefficients of determination were 0.91, 0.96, 0.99, 0.87, 0.85, 0.84 and 0.99 for the energy, carbohydrate, protein, moisture, fat, ash and crude fibre content of the extrudates respectively. For a good fit the coefficient of determination should not be less than 0.8. Coefficient of determination provides a measure of how well observed outcomes are replicated by the model, based on the proportion of total variation of outcomes explained by the model. It gives information about the goodness of fit of a model by providing information on how well the regression line approximates the real data points. Because values of R2 tend to increase as the number of variables increase, adjusted R2 is included in the validation process. The explanation of this statistic is almost the same as R2 but it penalizes the statistic as extra variables are included in the model [45,46]. Values of adjusted R2 were high for all the responses (Table 5). Except for moisture, there was no significant lack of fit for all the responses. These therefore suggest that the model equation was adequate in describing the proximate composition of the sorghum-cowpea extrudates. Among the independent variables, feed composition had the most effect followed by extrusion temperature. Feed moisture had the least effect on the proximate composition of sorghum-cowpea extrudates.

Numerical optimization and interactive graphs were used to optimize the various input variables and responses. The factor levels were adjusted from the interactive optimization plots until the highest desirability value possible (maximum is 100%) was obtained for the particular response in question. The value of such responsevariable at this point was considered the optimum. The optimum values of response variables are presented in Table 7. Optimum value for protein was 15.45% at feed composition of 20.2%, feed moisture of 20% and barrel temperature of 120 °C. The optimum values for lysine and methionine were 6.33 g/100 g at 20% cowpea flour, 21% feed moisture extruded at 124 °C and 1.64 g/100 g at 28% cowpea flour, 20% feed moisture, extruded at 120 °C respectively.

Conclusions

A breakfast cereal with improved protein content and satisfactory amino acid profile was produced from extruded sorghum-cowpea blends. The moisture content of the extrudates was low enough for theextrudates to keep well in storage if properly packaged. The secondorder model was found appropriate in predicting the proximate composition and essential amino acid profile of the sorghumcowpea extrudates. Feed composition had the most influence on the proximate composition and the essential amino acids, followed by feed moisture. All the essential amino acids and protein content of extrudates were in sufficient quantities for growing children.Acknowledgements

This work was funded in part from the fellowship award of The Federal Polytechnic Mubi and the World Bank Assisted Science and Technology Education Post-Basic (STEP-B) Project (Credit No:4304 UNI) of The Federal Polytechnic Mubi, Nigeria. Mr. Ibok U. Ibok is greatly acknowledged for operating the extruder and other laboratory equipment used in this work.References

- Olson RE (1975) Protein-calorie malnutrition. Academic Press, New York.

- Eggum BO, Beames RM (1983) The nutritive value of seed proteins. In: Gottschalk W, Muller HP (Eds). Seed proteins: biochemistry, genetics and nutritive value. Dr W. Junk Publishers, The Hague, pp. 499-531.

- Liener I (1979) Significance for humans of biologically active factors in soybeans and other food legumes. J Am Oil Chem Soc 56: 121-129.

- Singh U (1988) Antinutritional factors of chickpea and pigeonpea and their removal by processing. Plant Foods Hum Nutr 38: 251-261.

- Singh U, Jambunathan R (1989) Present status and prospects for utilization of chickpea. In: Chickpea in the nineties: proceedings of the second international workshop on chickpea improvement, 4th-8th December, ICRISAT Centre, India, pp. 41-46.

- Davis DW, Oelke EA, Oplinger ES, Doll JD, Hanson CV, et al. (1991) Cowpea. In: Alternative field crops manual.

- FAO (2010) FAOSTAT Food and Agriculture Organization.

- Nkama I, Angarawai I and Badau M H (1998) Bank data, production, commercialization, transformation, and consumption survey report. ROCAFREMI-WCAMRN Project P5-Food Technology of Millet.

- IITA (2011) International Institute for Tropical Agriculture, Bulletin of Tropical Legumes. A monthly publication of the tropical legumes II project. International Institute for Tropical Agriculture (IITA), Ibadan, Nigeria.

- FAO (2012) Food and Agriculture Organization FAOSTAT.

- NAS (1996) National Academy of Science. Lost crops of Africa: Grains 1: 127-213.

- Nahemiah D, Nkama I, Badau MH (2016) Application of response surface methodology (RSM) for the production and optimization of extruded instant porridge from broken rice fractions blended with cowpea. Int J Nutr Food Sci 5: 105-116.

- Filli KB, Nkama I, Abubakar UM, Jideani VA (2010) Influence of extrusion variables on some functional properties of extruded millet-soybean for the manufacture of ‘Fura’: a Nigerian traditional food. African J Food Sci 4: 342-352.

- Anuonye JC, Badifu GI, Inyang CU, Akpapunam MA, Mbajika VI, et al. (2007) Protein dispersibility index and trypsin inhibitor activity of extruded blends of acha/aoybean: a response surface analysis. Am J Food Tech 2: 502-511.

- Asare EK, Sefa-Dedeh S, Sakyi-Dawson E, Afoakwa EO (2004) Application of response surface methodology for studying the product characteristics of extruded rice-cowpea-groundnut blends. Int J Food Sci Nutr 55: 431-439.

- Bhandari B, D’Arcy B, Young G (2001) Flavour retention during high temperature short time extrusion cooking process: a review. Int J Food Sci Tech 36: 453-461.

- Guy R (2001) Extrusion cooking: technologies and application. Wood Head Publishing.

- Fellows PJ (2000) Food processing technology: Principles and practice, (2ndedn). Woodhead Publishing Limited, CRC Press, New York.

- Tayeb JG, de Valle C Barres, Bruno V (1992) Simulation of transport phenomena in twin-screw extruders In: Kokini JL, Ho CT, Karwe MV (Eds.) Food extrusion science and technology, Taylor & Francis, pp. 41-70.

- Iwe MO (2010) Handbook of sensory methods and analysis. Rojoint Communication Services Limited, Enugu, Nigeria, pp. 35-40.

- Annor GA, Sakyi-Dawson E, Saalia FK, Sefa-Dedeh S, Afoakwa EO, et al. (2009) Response surface methodology for studying the quality characteristics of cowpea (Vigna unguiculata)-based tempeh. J Food Process Eng 33: 606-625.

- Carley KM, Kamnewa NY, Reminga J (2004) Response surface methodology: Computational Analysis of Social and Organizational System (CASOS) Technical Report. CMU-ISRI.

- BS (1985) British Standard (812-103.1:1985), Now European Standards EN 933-1.

- Zasypkin DV, Lee TC (1998) Extrusion of soybean and wheat flour as affected by moisture content. J Food Sci 63: 1058-1061.

- AOAC (1991) Official Methods of Analysis of the Association of Official Analytical Chemists, (14thedn), Washington D.C.

- Pearson D, Egan H, Kirk RS, Sawyer R (1981) Pearson’s chemical analysis of foods, (8thedn), Churchill Livingstone.

- Nwabueze TU, Iwe MO (2006) Mass flow rate, nutrient composition and some functional properties of single screw extruded African breadfruit (Treculia africana) blends. J Food Tech 4: 50-58.

- Benitez LV (1989) Amino acid and fatty acid profiles in aquaculture nutrition studies. In: De Silva SS, (Ed.) Fish nutrition research in Asia: proceedings of the third Asian fish nutrition network meeting. Asian Fish Society Special Publication, Asian Fisheries Society, Manila, Philippines, pp. 23-35.

- Meyers HR (1976) Response surface methodology. Allyn and Bacon, Boston MA, USA, pp. 246.

- Iwe MO (2003) The science and technology of soybeans. Chemistry, nutrition, processing and utilization (1stedn). Rojoint Communication Services Limited, Enugu, Nigeria.

- MINITAB 14 (2003) Meet MINITAB Release 14 for Windows Manual. Minitab Inc. USA.

- Filli KB, Nkama I, Jideani VA, Abubakar UM (2011) Application of response surface methodology for the study of composition of extruded millet-cowpea mixtures for the manufacture of fura: a Nigerian food. African J Food Sci 5: 884-896.

- Olapade AA, Aworh OC (2012) Chemical and nutritional evaluation of extruded complementary foods from blends of fonio (Digitaria exilis Stapf) and cowpea (Vigna unguiculata L. Walp) flours. Int J Food Nutr Sci 1: 4-8.

- FAO (2002) Protein and amino acids requirements in human nutrition. Joint WHO/FAO/UNU expert consultation, pp. 9-10.

- Anuonye JC, Onuh JO, Egwim E, Adeyemo SO (2010) Nutrient and antinutrient composition of extruded acha/soybean blends. J Food Process Preserv 34: 680-691.

- Aranceta J, Pérez-Rodrigo C (2012) Recommended dietary reference intakes, nutritional goals and dietary guidelines for fat and fatty acids: a systemic review. Br J Nutr 107 Suppl 2: S8-S22.

- EUFIC (2015) European Food Information Council Review: facts on fats- dietary fats and health.

- AACC (2001) The definition of dietary fibre. Report of the dietary fiber definition committee to the board of directors of the American Association of Cereal Chemists. Cereal Foods World 46: 112-126.

- Turner ND, Lupton JR (2011) Dietary Fibre. Adv Nutr 2: 151-152.

- Singh S, Gamlath S, Wakeling L (2007) Nutritional aspects of food extrusion: a review. Int J Food Sci Technol 42: 916-929.

- Paes MC, Maga J (2004) Effect of extrusion on essential amino acids profile and color of whole-grain flours of quality protein maize (QPM) and normal maize cultivars. Revista Brasileira de Milho e Sorgo 3: 10-20.

- Anuonye JC (2012) Some functional properties of extruded acha/soybean blends using response surface analysis. African J Food Sci 6: 269-279.

- FAO/WHO (1991) Protein quality evaluation. Food and Agricultural Organization of the United Nations, Rome, Italy, pp. 66.

- Davidson S, Passmore R, Brock JF, Truswell AS (1975) Human nutrition and dietetics (6thedn), Longman Group Limited.

- Glantz SA, Slinker BK (1990) Primer of applied regression and analysis of variance. McGraw-Hill.

- Draper NR, Smith H (1998) Applied regression analysis, Wiley.