Journal of Food Processing & Beverages

Download PDF

Research Article

Enhanced Functional, Sensory, Microbial and Texture Properties of Low-Fat Set Yogurt Supplemented With High-Density Inulin

Ahmed Helal1*, Nawa N. Rashid2, Noha E. Dyab3, Mutlag M. Al-Otaibi4 and Tareq M Alnemr3,4

- 2Department of Dairy Science & Technology, Salaholden University, Kurdistan

- 3Department of Dairy Science and Technology, Alexandria University, Egypt

- 4Department of Food and Nutrition Sciences, King Faisal University, KSA

*Address for Correspondence: Ahmed Helal, Department of Food and Dairy Sciences and Technology, Faculty of Agriculture, Damanhour University, 22516 Damanhour, Egypt, Tel: +2 01002908422; Fax: +2 0453318537; E-mail: ahmed.helal@damanhour.edu.eg

Citation: Helal A, Rashid NN, Dyab NE, Otaibi MA, Alnemr TM. Enhanced Functional, Sensory, Microbial and Texture Properties of Low-Fat Set Yogurt Supplemented With High-Density Inulin. J Food Processing & Beverages. 2018;6(1): 11.

Copyright: 2018 Helal A, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

J Food Processing & Beverages | ISSN: 2332-4104 | Volume: 6, Issue: 1

Submission: 30 January, 2018| Accepted: 08 March, 2018 | Published: 14 March, 2018

Abstract

The influence of high-density inulin addition at different concentrations upon the yogurt characteristics and on the growth of the lactic acid bacteria of low-fat yogurt during cold storage at 5 °C for 14 days was investigated.

High-density inulin was incorporated into milk containing 0.1% of milk fat at 0, 1, 2 and 3%, this inulin-supplemented yogurt samples were compared with control samples (3.2% of milk fat without supplementation) whereas all treatments were inoculated with mixed cultures of Streptococcus thermophilus and Lactobacillus delbrueckiissp. bulgaricus. The chemical composition, pH, titratable acidity, acetaldehyde, apparent viscosity in addition to microstructure properties, texture profile analysis and sensory properties were measured during the storage.

Yogurt pH values and titratable acidity was not influenced by the addition of different ratios of inulin, while the addition of high-density inulin (1 and 2%) positively affected the acetaldehyde formation resulted in higher concentration than the low-fat without additives, as well as yogurt apparent viscosity which increased with inulin addition till 2% and was comparable to full-fat yogurt. The viability of L. delbrueckiissp. bulgaricus was enhanced by the addition of 1 and 2% of inulin, while the addition of 3% had negative effect. However, no effect was noted in case of Streptococcus thermophiles viability. The results indicated that the addition of inulin had significantly improved the rheological properties and microstructure. Consequently, low-fat yogurt with 1 and 2% inulin received higher scores for sensory and overall acceptance than did low-fat yogurt without inulin.

Keywords

High-density inulin; Set-type yogurt; Texture profile analysis; Starter viability

Introduction

Linking between food and health is becoming more and more essential in consumers’ daily lives, as they are trying to get foods that support some health benefits and lower the risk of consumers’ health problems.

In spite of the increasing awareness of healthy food benefits, the overconsumption of fatty foods has led to increasing obesity, which has become a worldwide problem. The consumption of low or nonfat food products could be important factor to reduce obesity.

In some dairy products, especially yogurt, the reduction of fat has negative effects on yogurt characteristics such as lack flavor, poor texture, weak body and undesirable rheological properties which led to lowering the consumer’s acceptability of that products, many studies have been concerned on finding different fat replacers and inulin has found to be a good fat sub acute in yogurt production [1].

Inulin is a dietary fiber consisting of a chain of fructose molecules with mostly a terminal glucose unitfound in several vegetables and fruits products, for industrial production, the chicory roots are the most suitable for extrication [2].

The characteristics and functionality of inulin are depending on the degree of its chain polymerization, Wada et al. reported that the Long-chain inulin is more stable, viscous and less soluble comparing to the shorter-chain inulin [3].

Numerous studies have discussed the effect of inulin as fat replacers by incorporating the stabilizers into the milk for the production of low fat dairy products.

In a study by Brennan and Tudorica, they used the inulin as a fat replacer in production of low-fat fermented skim milk, they reported that the concentration of inulin had a significant impact on the evaluations for texture and syneresis of the product [4]. Comparable outcomes were expressed for fermented cow’s milk with an inulin addition [1].

Kip et al. found inulin enhancement effect on the creamy feeling of stirred low-fat yogurt as well as on its apparent viscosity [5].

Inulin, apart from being used as a fat substitute, is also using as low-caloric sweetener and bulking agent, likewise as a texture modifier. Moreover, it has wide applications in various types of food like confectionery, salad dressings, fruit preparations, milk desserts, yogurt and fresh cheese, baked goods products like yogurts, mousses, ice cream, sauces and chocolate [6].

Regarding the definition of prebiotics, inulin can be also considered a prebiotic since its resistance to digestion in the upper part of the intestinal tract so that the metabolism takes place in the colon [7].

Fructan-based inulins and oligofructoses such as oligofructose are the most studied prebiotics; Numerous studies have discussed the certain health benefits of inulin consumption as a prebiotic such as reducing the risk of colon cancer, improving host resistance to invasion by pathogens, enhance minerals absorption and bioavailability especially of calcium and magnesium, reduce blood lipid level and improve the immune response, in addition increasing the digestibility of high-protein diets, and decreases fat absorption [8].

The effect of inulin on the quantitate of Lactobacillus casei in yogurt were studied by Aryana & McGrew and found a significant improvement in their counts where short, medium and long-chain inulin were used [9].

In manufacturing of frozen yogurt using inulin (2%), an improving effect on Lactobacillus acidophilus and Bifidobacterium lactis have been observed. In addition, the organoleptic properties such as overrun, viscosity and melting properties have been improved as well [10].

In addition to the dietary dosage of prebiotic, the degree of polymerization of inulin mainly affects the prebiotic activity [11]. Furthermore, using long-chain inulinas prebiotic showed more beneficial effects to an in vitro-cultured colon microbiota than shorter one [12].

In recent study by Canbulatand Ozcan on the effects of inulin chain length on the growth of Lactobacillus rhamnosus in probiotic yogurt, and found that the viability of L. rhamnosus was enhanced by the presence of short-chain inulin [13], in addition, the samples with short-chain inulin gained the highest acceptability scores.

Whereas the most economic important product around the world, yogurt could have considered as easy to be enriched by incorporating nutritional and pharmaceutical materials. Therefore, the objective of this study is to incorporate high-density inulin, apart from being a fat replacer, in the manufacturing of low-fat yogurt with functionality enhancement such as a prebiotic source. Also, to determine its influence on low-fat yogurt properties (physiochemical, microstructure, texture profile and sensory evaluation). Furthermore, to address its effect on the of lactic acid bacteria viability during the cold storage.

Materials and Methods

Full-fat cow’s milk and skim milk were obtained from the dairy pilot plant (Faculty of Agriculture, Alexandria University), highdensity inulin obtained from Sensus (Brenntag Química, Spain). Mesophilic mixed culture containing Streptococcus thermophilus + Lactobacillus delbrueckiissp. bulgaricus (Danisco, Kopenhag, Denmark)

Yogurt preparation

Both of milk (3.2% fat) or low-fat milk (0.1%) were heated to 90 °C for 10 min. with continuous stirring and then cooled to 45 °C and inoculated with starter culture and incubated at 45 °C until the forming of gel structure and then the fermentation was stopped by rabidly cooling and stored in refrigerator at (5±1) °C for 14 days. In case of inulin supplementation, different concentration of high density inulin (1,2 and 3%) were added to low-fat milk before heat treatment. The total solids were adjusted to be similar among all the different treatments (14 %) by adding skim milk powder. Three replicate trials for each treatment were conducted.

Chemical composition

The pH value was measured for the milk and different yogurt samples during storage period using a pH meter (model pH 211; Hanna Instruments, Woonsocket, RI). The titratable acidity was determined and expressed as g of lactic acid/100 g of yogurt. Acetaldehyde was determined using head-space gas chromatography and expressed as mg/Kg yogurt.

Viscosity analysis

Yogurt apparent viscosity during storage was measured using a rotational viscometer (DV-II+Pro Brookfield Engineering Laboratories, Inc. (USA). The analysis was carried out at 20 °C by using spindle (L2) at speed of 100 rpm for all samples. The viscosity reading was recorded as mPa.s.

Texture profile analysis

Texture Profile Analysis (TPA) were evaluated instrumentally using a texture analyzer (TexturePro CT V1.2 Build 9, Brookfield Engineering Labs, Inc. USA), as described by Vital et al. [14], Speed of cross-head was 1 mm/s and parameters measured were hardness, adhesiveness, cohesiveness, and springiness. For these tests, samples were taken out of the refrigerator (4 °C) just before test operation. Measurements were conducted in triplicate.

Yogurt microstructure

The microstructure of inulin supplemented yogurt samples was examined by Scanning Electron Microscope (SEM). Small pieces of yogurt samples were fixed by immersing them immediately in 4F1G (4% formaldehyde, 1% glutaraldehyde) in phosphate buffer solution (pH 7.2) at 4 °C for 3 hours. The fixed samples were then post fixed in 2% OsO4 in the same buffer at 4 °C for additional 2 hours. Samples of were washed in the buffer and dehydrated at 4 °C through a graded series of ethanol. Samples of testes were dried by means of the critical point method, mounted using carbon paste on an aluminum stub and coated with gold up to a thickness of 400 Å in a sputter-coating unit (JFC-1100 E). Observations of sperm morphology in the coded specimens were performed in a scanning electron microscope (Jeol JSM-5300, Japan).

Microbial analysis of yogurt samples

For microbial analyses, serial 10-fold dilutions of each sample were made in peptone water (0.15%, w/v) and plated in duplicate. For the enumeration of Lactobacillus bulgaricus, appropriate peptone water dilutions of each sample were plated in duplicate onto de Man-Rogosa-Sharpe (MRS agar) Streptococcus thermophilus was enumerated on ST medium and all plates incubated aerobically at 37 °C for 48 h.

Sensory evaluation

To evaluate the consumer acceptance of the yogurt inulin mixture, the experimental products were evaluated in terms of their appearance, texture, flavor and overall acceptability of each sample using the nine-point hedonic scale using the protocol as detailed described by [15], the scale of 1-9 points were used, where 1 corresponds to “extremely dislike” and 9 to “extremely like”. 20 panelists, with sufficient background of scaling procedures, have evaluated all the samples at day 1, 5, 10 and 14 of storage. In addition to the nine-point hedonic scale; panelists were also asked to note any perceived unnatural characteristics for appearance, texture and flavor.

Statistical analysis

All data are presented as mean±SD for three replicates for each sample. Univariate Analysis of Variance (ANOVA) was applied using Stat graphics 16.1.11 (Stat Point Technologies, Inc. Virginia, USA) when multiple comparisons were performed. The differences were considered significant at P<0.05.

Results and Discussion

Physiochemical properties

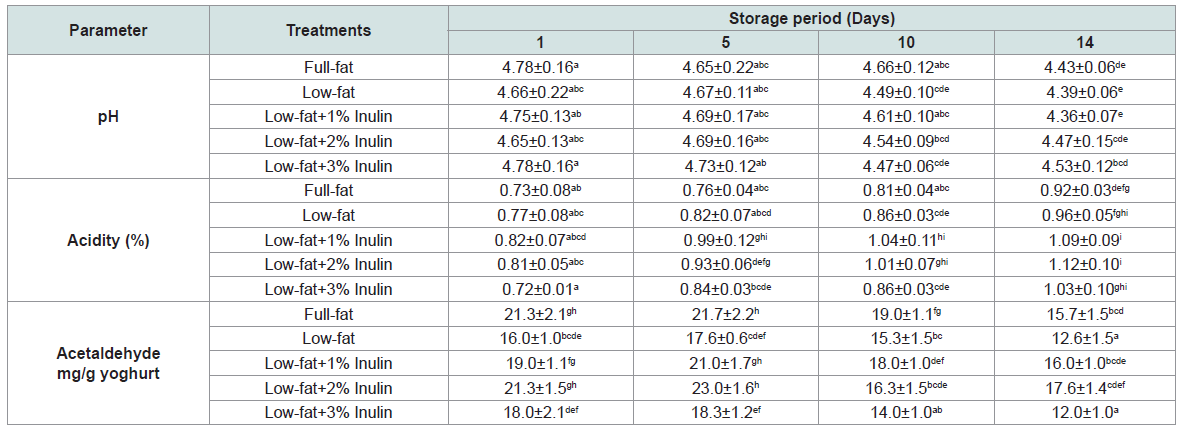

The physiochemical properties of yogurt samples were determined freshly and throughout refrigerated storage period. The pH values as one of the important indicator of yogurt properties have been determines and the data is shown in Table 1; the pH values were between 4.65 and 4.78 on day 1 for the different treatments, and however during storage a statistically significant (P<0.05) lower values were obtained and continued till the end of storage to record values between 4.36 and 4.53, but no significant differences between the different treatments was achieved. The pH values were not significantly affected by the inulin addition neither inulin percentage. Similar studies, which used inulin as fat replacer with yogurt, confirmed that the inulin does not significantly affect the pH values [1,16].

Titratable acidity of different yogurt treatments has been determined and the results as percentage based on lactic acid are shown in Table 1. Yogurt titratable acidity was ranged between 0.72 and 0.82% after the manufacture, regarding the low-fat treatments no significant differences were noticed comparing to full-fat milk yogurt, furthermore, titratable acidity was not influenced by addition of inulin. During the refrigerated storage, the low-fat yogurt treatments showed slight variability of titratable acidity value respect to those found in full-fat yogurt. The storage time affected the titratable acidity value, which was found to have a significant increasing behavior among all the different treatment and reached (0.92 and 1.12%) at the end of storage period. Means in a row and columns in the same parameter with different alphabetical superscripts are significantly different (P<0.05).

The flavor of fermented milk products is mainly formed during the fermentation or degradation process of milk and additives components, the major flavor component and most important one is acetaldehyde. Regarding the role of acetaldehyde in yogurt flavor, Tamime and Deeth found the optimal concentration of acetaldehyde to give sufficient flavor is between 23 and 41 mg/kg of yogurt [17].

The acetaldehyde concentration during storage is shown in Table 1. The full-fat yogurt showed significant higher acetaldehyde concentration respect to the low fat one without additives (21.3 and 16 mg/Kg, respectively), however the addition of inulin decreased this gap, as the addition of 1 and 2% of inulin showed similar concentrations respect to the full-fat one, this could be a result of supporting effect of the prebiotic on starter culture growth and metabolic activities.

The inulin effect was continuing during the storage period as well; as shown in Table 2, slight increasing in acetaldehyde concentration was noticed until the 5th day of storage, then a general and expected decrease in acetaldehyde concentration was achieved at the end of storage period as affected by the alcoholdehydrogenase activity of yogurt starters [17].

At the end of refrigerated storage of yogurt, the addition of inulin (1 and 2%) kept their positive effect on acetaldehyde formation resulted in higher concentration than the low-fat without additives. In addition, the concentration of 3% inulin showed significant lower acetaldehyde concentration in the beginning till the end of refrigerated storage (18 and 12 mg/Kg, respectively).

Rheological properties

Rheological properties and texture characteristics are critical parameters in sensory evaluation and in consumer acceptability in yogurt.

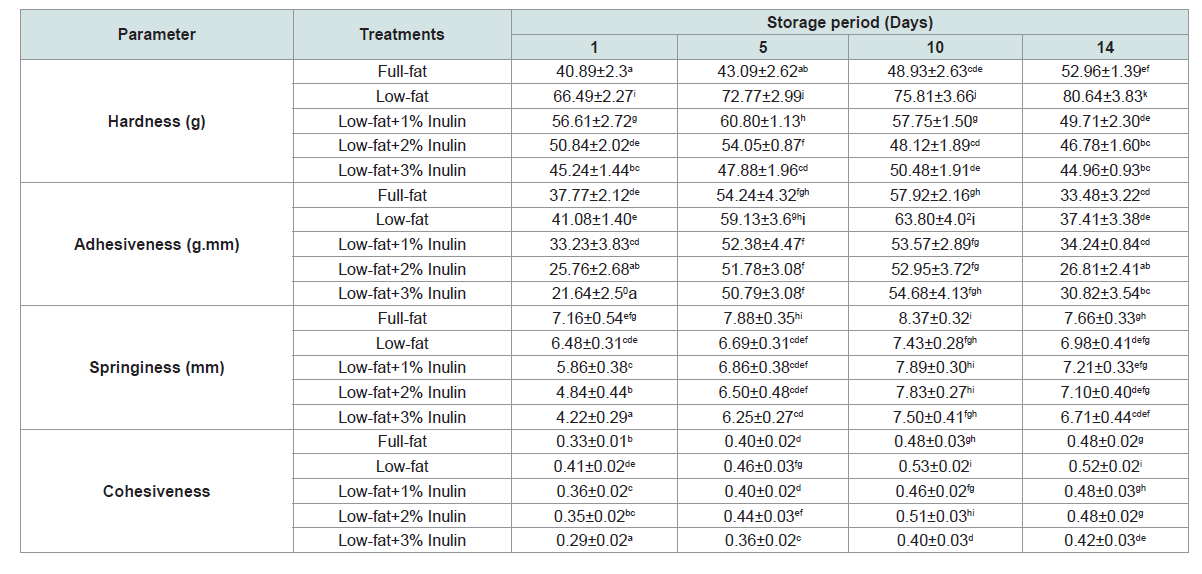

Yogurt apparent viscosity has been evaluated during 14 days of refrigerated storage and the data are shown in Figure 1.

Since apparent viscosity is affected by different factors such as milk composition, heat treatment of milk and additives [18], the apparent viscosity of the non-inulin supplemented low-fat yogurt showed significant lower values than those full-fat yogurt (155.6±9.1 and 205.0±5.0 mPa.s. respectively).

Therefore, the addition of inulin has significantly affected the yogurt viscosity resulted in increasing the viscosity value with the inulin addition. Additions of inulin to yogurt can increase the viscosity depending on its effectiveness in absorbing water. The addition of 1 and 2% inulin has increased the viscosity respect to the low-fat yogurt by 14.7 and 17.9%, respectively. While the addition of 3% showed 8% increasing.

Taking into consideration the similarity of total solids concentration among the different treatment.

Therefore, the effect of inulin was not only due to the influence of the high total solids of yogurt, but it is believed to involve the hydroscopic nature of inulin, where it provides water binding and subsequently are forming a gel-like network within the yogurt matrix affecting the microstructure and the viscosity. Similar output was observed by Akin et al. and Modzelewska-kapitulaand Klebukowska [19,20].

In similar experiment carried out by Isik et al. on frozen yogurt, they found that the incorporation of inulin increased the viscosity between 19 and 52% compared to that of reduced-fat control [21].

Regarding the fact that yogurt is storable product, it was very important to evaluate the storage effect on apparent viscosity during the 14th day of storage at 5 °C. As shown in Figure 1, the viscosity of full-fat yogurt was stable with slight (but non-significant) decreased gradually during the storage, resulted in significant decrease at 14 days of storage (187.6±7.1 mPa.s.), in case of low-fat yogurt similar results were achieved, whereas the viscosity was significantly decreased by increasing the storage period. Similar studies have reported a decrease of apparent viscosity with increasing storage time while Izadi, 2015 declared that the viscosity of yogurt can increase till the 7th day of storage and then decreased again. Another study by Sahan et al. found that yogurt viscosity can increase gradually over storage because of the rearrangement of protein matrix interaction [22,25].

On the other hand, a significant increase until the 5th day of storage was noticed in case of 1, 2 and 3% inulin added.

These changes in the different yogurt type led to have similar viscosity and comparable between the full-fat and inulin treated yogurt. However, by increasing the storage time, differences between the full-fat yogurt and low-fat yogurt with inulin appeared again, as well as between the different concentrations of inulin.

At the end of storage, the non-inulin supplemented low-fat yogurt kept its behavior and recorded the lowest viscosity (131.3±10 mPa.s.). Furthermore, the inulin treated yogurts in spite of showing higher viscosity than the low-fat non-treated one, they were significantly lower than the full-fat one which showed the highest value of viscosity (187.6 ±7.1 mPa.s.).

Figure 1: Apparent viscosity values measured during storage in Full-fat yogurt (■), Low-fat yoghurt (▲), Low-fat yogurt +1% Inulin (●), Low-fat yogurt +2% Inulin (♦) and Low-fat yogurt +3% Inulin (ӿ). (The error bars represent standard division of means).

Therefore, the addition of 1 and 2% of inulin were significantly higher than that found in case of using 3% inulin by the end of storage (147.6±7.5, 160.3±8.9 and 137.6±7.5 mPa.s., respectively).

This different effect of inulin concentration has been previously demonstrated by Gonzalez-Toma’s et al. whom studied the factors that may contribute to the inulin effect on the viscoelastic properties of the dairy products. The behavior of inulin was not only affected by its concentration or even its type, but the type of milk and its fat content as well as the present of other additives, especially polysaccharides.

That varied factors affect the aggregation of inulin as waterstructuring agent with the protein of milk, whereas that structural network which formed during the fermentation process affect the viscosity properties of yogurt [5].

One of the important parameter affecting the rheology properties of yogurt is the protein/polysaccharide ratio, and it is important to control that ratio to obtain the requested benefits of this interaction. In the case of using 3% inulin, this high concentration of inulin could form strong interaction with milk protein, Schmitt & Turgeon et al., Kruif et al. reported that strong associative interaction between protein and polysaccharide could negatively affected the solubility of the formed complexes which led to decrease its hydration capacity and decreasing in the viscosity as result [26,27].

This decrease of viscosity during the storage in inulin treated yogurt was also observed by Modzelewska-kapitulaand Klebukowska who found that the addition of 2.7% of inulin showed high viscosity at 7th day of storage and then decreased [20]

This hypothesis has been explained by Guggisberg et al. as they suggested that the presence of inulin could form a second network which partly retard the principle protein network formation [1], this network assumed to be stronger and affecting the yogurt viscosity and rheological properties during the first seven days of storage followed by degradation and resulting in weak network with increasing the storage period.

Textural properties of yogurts were analyzed for the different treatments as well as during storage, Table 2 shows changes in texture properties of the yogurts determined by Texture Profile Analysis (TPA). Hardness, one of the important texture parameters showed a significant difference (P<0.05) among the different yogurts treatments. The fat content level was mainly affected the hardness, whereas the low-fat yogurt showed significantly higher hardness than those found in full-fat (66.49±2.27and40.89±2.31 g, respectively).

Similar results were reported by Atamian et al. who found that increasing fat level resulted in decreasing the hardness in yogurt and Labneh [28]

The addition of inulin led to significant decrease (P<0.05) in yogurt hardness respect to the low-fat yogurt, but the inulin treatment keeps significant higher respect to the full-fat yogurt. Moreover,the hardness of yogurt was a percentage of inulin dependably, thus the increase of inulin addition until 3% showed the most affected percentage resulted in lower hardness between the different inulin concentrations.

This decrease is may be due to the relation between hardness and water content, as it is known that inulin is able to adsorb or bind water which weakens the casein micelles-texturized inulin gel network leading to a less firm yogurt.

Hardness of full-fat yogurt increased systematically to reach 52.96±1.39 g after 14 days of refrigerated storage.

In different studies on the influence of storage on yogurt rheological properties by Hanif et al., Ayar et al. demonstrated that hardness increased gradually by increasing storage period [22,29].

The treated inulin yogurt showed different behavior during the storage, significant increase was noticed until 5th day of storage when 1 and 2% inulin was used, while 3% showed significant increase until 10th day of storage. At the end of storage, a significant decrease wasobserved.

The decrease in hardness with increasing the storage period of inulin treatments is believed to be related to the degradation in the second network after 7th days of storage which led to structure modification and reduce yogurt hardness.

This different behavior of inulin enriched yogurt led to decrease the gap between the hardness of full-fat yogurt and low-fat yogurt, since in 10th day of storage the hardness of full-fat yogurt was equal to yogurt with 2 and 3% inulin.

Yogurt adhesiveness as one of the important texture characteristic parameter found to be a positive effect on the thickness of the yogurt and is used as one of the judgments parameters on the products stability during storage. Adhesiveness value is reported in Table 2, the effect of fat level on adhesiveness was very limited and the differences were not significant between full and low-fat yogurt (37.77±2.12 and 41.08±1.40 g.mm, respectively). Atamian et al. in their research on Labneh, they reported that the fat content didn’t influence the adhesiveness or adhesive force [28]. The effect of inulin supplementation was found to be a concentration dependably, whereas, more increase in the concentration of inulin induced more significant decrease in adhesiveness. The lowest adhesiveness value (21.64±2.50 g.mm) were found in case of using 3% Inulin. Similar results were obtained by Tavakolipour et al. as they found that the increasing of fat replacers concentration (gelatin and waxy corn starch) led to decrease the adhesiveness [30]. This effect could be a result of hydrocolloid concentration which increases the formation of a weak three-dimensional network.

It is well known that the protein-polysaccharide interactions and the aggregation and gelation behavior have significant importance in the structure, rheological properties and physical stability of multicomponent food systems [31,35].

This polysaccharide-protein interactionmay depend on various environmental conditions such as pH, ionic strength and temperature; whereas the charge and nature of biopolymers play vital role in such interactions [36].

When the solution pH is near to protein Isoelectric point (pI), the chance to form weak complex from the polysaccharide-protein interaction is more than when the pH is higher than the protein pI [32,37]. However, the pH in the different yogurt treatments was almost similar and near to the protein pI, but it is believed to involve the inulin concentration on the decreasing effect on yogurt adhesiveness.

Dickinson has also demonstrated that the concentration of biopolymers is highly affecting the rheology of the food matrix [38]. In the present of high concentration of inulin which having similarly charged, whereas it could repel each other resulting in unstable system duo to the net repulsion, and that would lead to weaker complex even in pH higher than the protein pI [39], this hypothesis could explain the decreasing in the adhesiveness with increasing the inulin concentration which provide high ionic strength.

Generally, adhesiveness of yogurts increased until the 10th day of storage, however the increasing rate was different from a treatment to other. Moreover, the adhesiveness value at 5 and 10 days of storage were almost similar and the inulin treatments were comparable to the full-fat yogurt. In addition, the low-fat yogurt without inulin supplementation showed the highest adhesiveness value during the storage (59.13±3.69 and 63.80±4.02 g.mm for 5 and 10 days of storage, respectively).

After 14 days of storage, the recorded increase in adhesiveness value was followed by significant decrease at the end of storage period, whereas a significant (P<0.05) reduction in the adhesiveness among all treatment were observed, the inulin treatments showed significant reduction than the non-supplemented low-fat yogurt, but was similar to the full-fat yogurt.

Similar behavior was reported by Abou-Soliman et al., Ayar et al. who found an increase in adhesiveness of yogurt during storage followed by a reduction at the end of storage [5,40].

The springiness (mm) and Cohesiveness values as reported in Table 2 were influenced by the ratio of fat content and inulin level in yogurt. Full-fat yogurt showed the highest springiness followed by the low-fat yogurt, while the addition of inulin decreased the springiness with increasing its ratio. The yogurt was ranked in terms of springiness in the following order: full-fat>low-fat>low-fat+1% inulin>low-fat+2% inulin>low-fat+3% inulin.

While the cohesiveness showed different behavior; the lowfat yogurt was slightly higher than the full-fat one (0.41±0.02 and 0.33±0.01, respectively). Moreover, the addition of inulin has affect the cohesiveness values and the results ranked in the following order: low-fat>low-fat+1% inulin>low-fat+2% inulin>full-fat>low-fat+3% inulin.

As many previous studies have found that decreasing the fat concentration of yogurt had a negative effect on rheological characteristics this experiment assumed that the addition of inulin decreases the differences in rheological characteristics which found in case of the comparing between full and low-fat yogurt.

For example, low-fat+1% inulin and low-fat+2% inulin treatments showed cohesiveness values (0.36±0.02 and 0.35±0.02, respectively) which are lower than the non-inulin low-fat yogurt and higher than the full-fat yogurt.

However, during storage, springiness and cohesiveness has been increased gradually until the 10th day of storage then a decreased have been observed among the different treatments, but the increasing rate of springiness was different and influenced by the presence of inulin. At 10th day of storage the differences among the treatments was at the lowest rate, resulted in similarly and comparable characteristic between full-fat yogurt and those contain inulin.

Similar findings were obtained by Ayar and Gurlin who found that yogurt springiness has increased in the yogurt between 1st and 10th days of storage [5], while at the end of 20th day, a decrease was observed. Also, Lee et al. have found increasing of some textural parameters such as cohesiveness [41], chewiness, springiness and brittleness of the yogurt-cheese with increasing storage period.

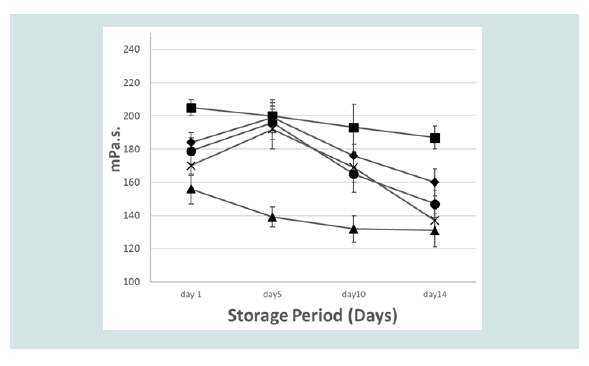

Microstructure observation by scanning electron microscope

Scanning electron microscope is often using to investigate the fermented milk microstructure by focusing on the protein matrix.

Scanning electron micrographs of the different yogurt after 1 day of storage period are presented in [Figure 2].

The effect of fat content had clear effect on the microstructure of yogurt, as it was observed the full-fat micrograph [Figure 2A] showed a finer network and more homogenized matrix than those in the lowfat one [Figure 2B], Furthermore, the increasing in fat content led to high cohesive and less coarse network.

These differences on the microstructure are reflected the negative effect of reducing fat content in yogurt.

Guggisberg et al. have observed similar effect when compared a full-fat yogurt with low fat-yogurt [1].

Regarding the effect of inulin on yogurt microstructure, the scanning electron micrographs of 1, 2 and 3 % of inulin is shown in [Figure 2C-2E], respectively.

The addition of inulin enhanced the gel microstructure and showed finer network and more homogeneous compared to noninulin supplemented low-fat yogurt sample.

The concentration of 1 and 2% of inulin were almost similar [Figure 2C and 2D], however the 3% inulin showed larger pores and less firm network.

However, in previous study, Fagan et al. observed non -significant effect of inulin in microstructure compared to the control (no inulin) [42], and similar observation was reported by Guggisberg et al. when comparing full-fat yogurt without inulin and full-fat yogurt with different ration of inulin [1].

In our case, the enhancement of inulin was clear, as it had compared to low-fat yogurt which is negatively affected the microstructure, this enhancement effect could be due to the inulin ability to structure water. Furthermore, some sub-micron crystalline inulin particles can form an insoluble gel network in the water phase [5].

Another hypothesis of inulin effect in yogurt microstructure,which is that inulin may contribute to the forming of protein network during the fermentation process, but was not possible to verify this hypothesis since the inulin was not fluorescently labelled [1].

Figure 2: (A) Microstructure observation by scanning electron microscope for control full-fat yogurt, (B) Low-fat yogurt, (C) Low-fat yogurt +1% Inulin, (D) Low-fat yogurt +2% Inulin and (E) Low-fat yogurt +3% Inulin.

Effect of high-density inulin addition on yogurt starter viability

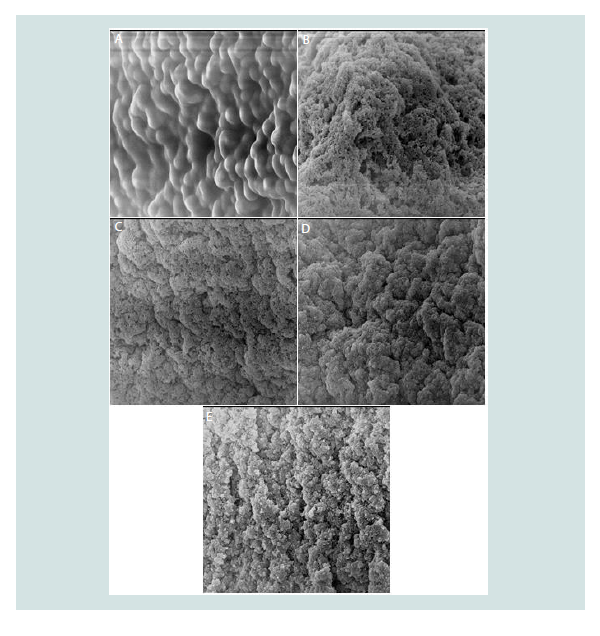

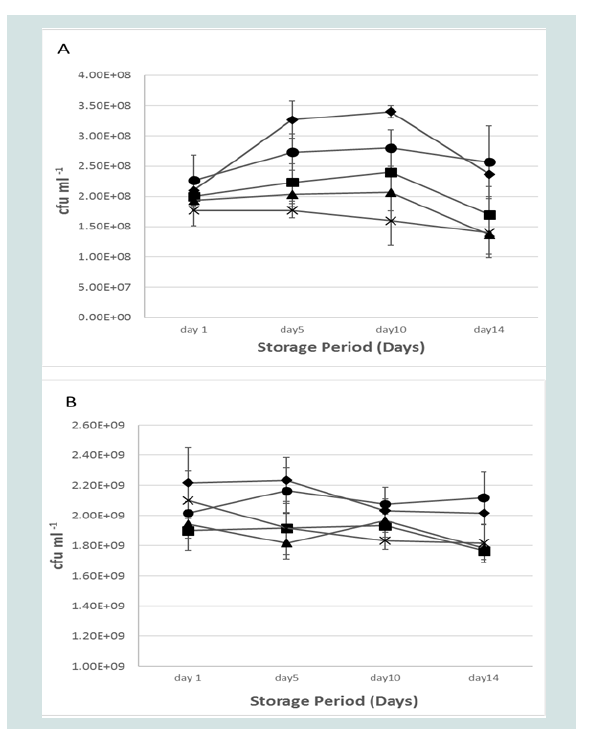

The effect of inulin addition on the microbial viability of yogurt was evaluated during refrigerated storage and the data is shown in [Figure 3].

Inulin as prebiotic had affected the lactobacillus growth during fermentation as well as during yogurt storage, a slight increase in lactobacillus count were detected when inulin was added to lowfat yogurt at the first day of storage [Figure 3A]. The effects of inulin on lactobacillus growth were more noticeable after 5 days of storage, where the addition of inulin recorded the highest count of lactobacillus .

In case of full or low-fat yogurt the lactobacillus counts during the storage time were between 1.78 : 28 and 1.378 : 1.938 CFU/ml, respectively.

During storage the highest count were reached at 10 days of storage in case of using 2% inulin (3.48 CFU/ml).

de Souza Oliveira et al. found that using inulin as fat replacers in fermented milk significantly improves the growth and viability of Lactobacillus acidophilus, Lactobacillus rhamnosus and Bifidobacterium lactis even in case of low inulin concentration [43].

Aryana and Mcgrew have used a concentration of 1.5% (w/v) of inulin in production of fermented milk and they found that concentration is sufficient to invigorate the growth and retain the feasibility of probiotic strains [9].

Furthermore, the presence of inulin influenced change in the total population of lactic acid bacteria during refrigerated storage, as in case of the absence of inulin the reduction was about 15 to 29% while using inulin, the population of lactic acid bacteria was either increased or remained unchanged during storage. Similar outcome was reported by Montanuci et al. [44].

The continuous effect of inulin on the development and viability of probiotic bacteria during storage at refrigerator have been previously reported by Akin et al. [19].

On the other hand, increasing inulin percentage to 3% negatively affected the lactobacillus counts especially during the storage and the count was decreased from 1.778 to 1.48 CFU/ml which was significantly lower than other treatments.

Previous study by de Souza Oliveira reported positive effect of inulin as prebiotic in increasing the probiotic growth in yogurt induced by metabolic interactions among lactic acid bacteria and the metabolization of partial inulin during fermentation process [43].

In different studies on using inulin as a prebiotic in yogurt or other fermented products, it was found that inulin could increase probiotic and starter bacteria viability during fermentation process and storage [45].

Figure 3: Comparisons of viability of starter during refrigerated storage in yogurt. (A) Comparisons of viability of Lactobacillus bulgaricus. (B) Comparisons of viability of Streptococcus thermophilus in Full-fat yogurt (■), Low-fat yogurt (▲), Low-fat yogurt +1% Inulin (●), Low-fat yogurt +2% Inulin (♦) and Low-fat yogurt +3% Inulin (ӿ). (The error bars represent standard division of means).

On the other hand, Montanuci et al. didn’t find effect of inulin on lactic acid bacteria viability in Kefir, and concluded that the milk type and starter influence the inulin effect on survival of acetic acid bacteria [44].

Streptococcus thermophilus was mentored in yogurt samples either with or without inulin after 1, 5, 10 and 14 days of refrigerated storage and the data is presented in [Figure 3B].

At the first day of storage, constant viability of Streptococcus thermophilus was achieved among the different yogurt types, no significant influence of inulin on were observed.

Generally, the count ranged from 1.99 to 2.229 CFU/ml yogurt, this count was consistent in qualitative term with those reported by Zacarchenco PB and Massaguer-Roig [46,47].

In case of plain yogurt (without inulin supplementation) the viability of Streptococcus thermophilus during the 14 days of storage did not significantly change and ranged between 1.779 :1.99 and between 1.789 :1.949 CFU/ml for full and low-fat yogurt, respectively.

Noticeable differences were achieved during the storage, as the inulin treatments showed slight higher count of Streptococcus thermophilus after 5 and 10 days of refrigerated storage comparing to the non-treated inulin treatments.

This phenomenon could be related to the hypothesis of the synergistic effect between Streptococcus thermophilus and the other microorganisms [41], since inulin led to increase the lactobacillus viable count

Sensory characteristics

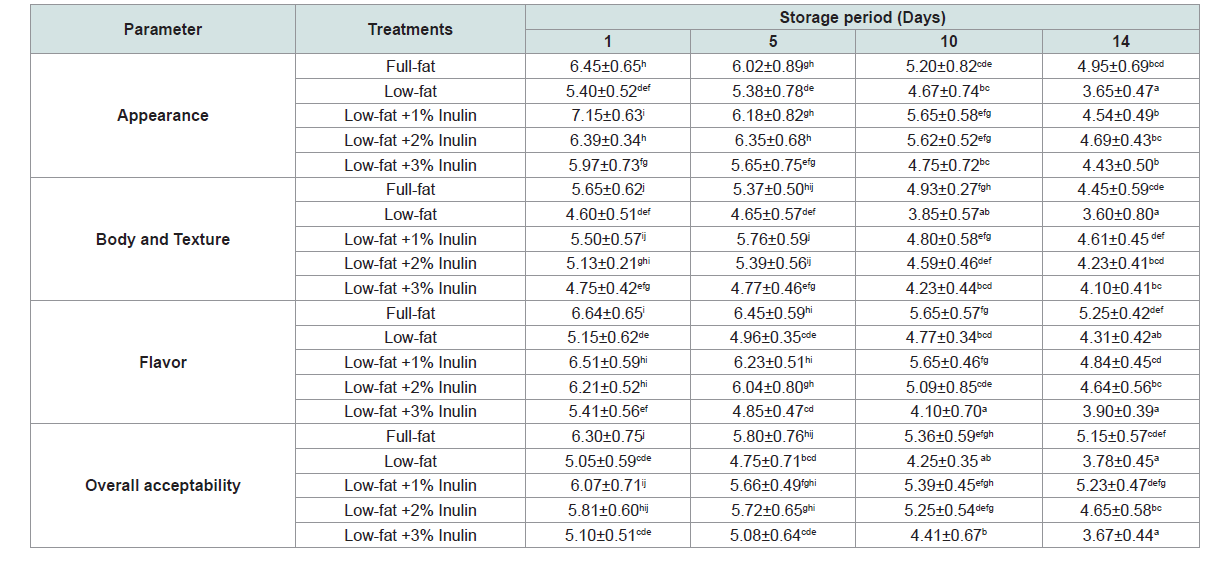

Yogurt is a ready to eat food, which doesn’t need any further treatment or cocking, therefore, the sensory characteristics such as appearance, flavor, texture and overall acceptability were evaluated after manufacturing and during storage and the results are shown in Table 3.

The mean score of appearance for yogurt with 1% inulin was significantly higher than the full-fat one, while as reported in Table 3, the increasing of inulin levels negatively affected the appearance scores. However, the 3% inulin treatment was significantly lower than the full-fat yogurt, but it was significantly higher than the non-inulin supplemented low-fat yogurt.

Low-fat non-treated yogurts had a mean score below the other yogurt.

Syneresis as defective factor on appearance was observed only in the low-fat yogurt, while the addition of inulin reduced the visually detected syneresis resulted in enhancement the appearance of yogurt.

Guggisberg et al. have found similar data, as they reported that the usingof inulin up to 2% reduced the syneresis respect to nontreated low-fat yogurt [1].

The effect of storage period on appearance is also shown in Table 3, generally there was a decrease in yogurt appearance with increasing the storage period. This decrease was significantly noticed especially at 10th and 14th day of storage.

Among the different yogurt, the low-fat non-treated yogurt kept the lowest appearance score during and until the end of storage. The ranked of mean score of appearance for yogurt have been slightly changed regarding the 1st day of storage and became in the following order: full-fat>low-fat+2% inulin>low-fat+1% inulin>low-fat+3% inulin>low-fat.

Regarding the texture of yogurt, sensory evaluation was performed on textural and body characteristics in order to obtain data that could support the texture profile analysis and rheological properties.

Results in Table 3 indicate that the inulin addition enhanced the low-fat yogurt texture properties and became comparable to those found in full-fat yogurt; furthermore, the addition of inulin in some treatments led to increase the mean score of texture than the full-fat treatment. Similar to appearance, the increasing of inulin level decreased the texture score, however this decrease was not significantly

During storage, slight modifications on texture score was achieved; in case of non-treated yogurt (full or low-fat) the mean score of texture was gradually decreasing with increasing storage, however it was not significant in the first five day of storage, but later was significantly lower.

In case of inulin treatments, as shown in Table 3, a noticed increase was observed during the first days of storage, especially in inulin level of 1 and 2%. This increase was not continuous as in 10th days of storage a significant decrease was achieved again.

The enhancement effect of inulin on texture properties is in line with the texture profile analysis evaluation, this effect could be a sequence of inulin gel-like network, which could be formed within the yogurt matrix. Moreover, the data obtained by the sensory evaluation are confirming the noticeable change in viscosity and texture profile after 10th days of storage, since the second network has been reported before to be degraded in the second week of storage, which resulted in the decrease on texture and body mean score.

Previous study by Guggisberg et al. reported the positive effect of inulin on firmness and creaminess values in enriched inulin low-fat yogurt [1].

Also in stirred low-fat yogurt, Kip et al. found that inulin enhanced the creamy mouth-feel [5].

Yogurt is categorized as a fresh food with a refreshing flavor, a smooth viscous gel, and a slight sour taste. Since the reducing of fat level in yogurt negatively affect the flavor, it was important to evaluate the consumers flavor score (taste and aroma) regarding the effect of inulin and its percentage.

As shown in Table 3, the full-fat yogurt gained the highest mean score among all the yogurt treatments, while the non-treated low-fat yogurt had the lowest flavor score.

Inulin addition had significantly increased the mean flavor score of low-fat yogurt and was almost similar to those in full-fat.

The results in Table 3 indicate that the mean scores for flavor of both 1 and 2% inulin were significantly higher than the low-fat yogurt. However, the increase of inulin to reach 3% have negative effect and showed significant decrease of mean scores for flavor respect to the lower inulin level, but the value was still in acceptable range and was not significantly different from that in low-fat yogurt.

Similar results were observed while evaluating the flavor during storage, whereas there was noticeable gradually decrease of flavor with increasing the storage time, but the enhancement behavior of the presence of inulin was still noticed.

At the end of storage period, the full-fat yogurt was still better liked by the consumers and therefore gained the highest flavor mean score. Furthermore, there was no significant difference in flavor evaluating between the full-fat and low-fat with 1% inulin, while the other treatments were significantly lower than the full-fat one.

This suggests that addition of inulin as fat replacer especially in level of 1 and 2% were better accepted by consumers in the different varieties of yogurt.

In case of overall acceptability, the data in Table 3 indicate that the overall acceptability was aligned with the other sensory characteristics.

Full-fat yogurt was significantly different (p<0.05) from the lowfat one, and scored the highest overall acceptability, while in case of the presence of inulin, the overall acceptability score was increased and being slight similar comparing to the full-fat yogurt.

The mean score of low-fat yogurt with 1 or 2% inulin were not significantly different from the full-fat treatment, but low-fat yogurt containing 3% inulin showed overall acceptability significantly lower than full-fat yogurt as well as lowers than the case of using 1or 2% inulin.

The overall acceptability among all treatments were decreasing with increasing storage period, and the mean score were ranked as follow; low-fat+1% inulin>full-fat>low-fat+2% inulin>low-fat>lowfat+3% inulin.

The increasing of inulin level and however showed significant enhancement comparing to the no inulin low-fat yogurt, but it was clear that the sensory characteristics was decreasing and resulted in negative feedback from panelists especially in case of 3% inulin but was still in acceptability range.

Conclusion

The effects of high-density inulin addition on low-fat yogurt characteristics were investigated. using 1 and 2% of high-density inulin successfully produced low-fat yogurt comparable to full-fat yogurt.

The addition of inulin has positively affected the yogurt apparent viscosity.

The texture profile analysis of yogurt indicates a remarkable effect and decreased the Hardness and Cohesiveness of low-fat yogurt as simulate the full-fat percentage.

The enhancement effect of inulin was also observed by the scanning electron microscope, this effect is mainly due to possibility of inulin to build a second network, however it was not visible by SEM.

The inulin enhanced the viability of L. delbrueckiissp. bulgaricus, but didn’t significantly affected the viability of Streptococcus thermophilus.

Regarding the sensory evaluation, higher score of inulin treatments (were obtained comparing to low-fat yogurt. The results were comparable to those obtained from full-fat yogurt.

This study suggests the addition of high-density inulin as fat replacer with technological and nutraceutical properties especially inlevel of 1 and 2% to produce low-fat yogurt with favorable accepted characteristics was possible.

References

- Guggisberg D, Cuthbert-Steven J, Piccinali P, Butikofer U, Berhard P (2009) Rheological, microstructural and sensory characterization of low-fat and whole milk set yoghurt as influenced by inulin addition. Int Dairy J 19: 107-115.

- Srisuvor N, Chinprahast N, Prakitchaiwattana C, Subhimaros S (2013) Effects of inulin and polydextrose on physicochemical and sensory properties of low-fat set yoghurt with probiotic-cultured banana puree. LWT-Food Sci Technol 51: 30-36.

- Wada T, Sugatani J, Terada E, Ohguchi M, Miwa M (2005) Physicochemical characterization and biological effects of inulin enzymatically synthesized from sucrose. J Agric Food Chem 53: 1246-1253.

- Brennan CS, Tudorica CM (2008) Carbohydrate-based fat replacers in the modification of the rheological, textural and sensory quality of yoghurt: comparative study of the utilisation of barley beta-glucan, guar gum and inulin. Intl J Food Sci Technol 43: 824-833.

- Kip P, Meyer D, Jellema RH (2006) Inulins improve sensoric and textural properties of low-fat yoghurts. Int Dairy J 16: 1098-1103.

- Toneli JT, Murr FE, Martinelli P, Fabbro IM, Park KJ (2007) Optimization of a physical concentration process for inulin. J Food Eng 80:832-838.

- Hughes R, Rowland IR (2001) Stimulation of apoptosis by two prebiotic chicory fructans in the rat colon. Carcinogenesis 22: 43-47.

- Manning TS, Gibson GR (2004) Prebiotics. Best Practice and Research: Clinical Gastroenterology 18: 287-298.

- Aryana KJ, McGrew P (2007) Quality attributes of yogurt with Lactobacillus casei and various prebiotics. LWT-Food Sci Technol 40: 1808-1814.

- Rezaei R, Khomeiri M, Aalami M, Kashaninejad M (2014) Effect of inulin on the physicochemical properties, flow behavior and probiotic survival of frozen yogurt. J Food Sci Technol 51: 2809-2814.

- Van Loo J (2004) The specificity of the interaction with intestinal bacterial fermentation by prebiotics determines their physiological efficacy. Nutr Res Rev 17: 89-98.

- van de Wiele T, Boon N, Possemiers S, Jacobs H, Verstraete W (2007) Inulin-type fructans of longer degree of polymerization exert more pronounced in vitro prebiotic effects. J Appl Microbiol 102: 452-460.

- Canbulat Z and Ozcan T (2015) Effects of short-chain and long-chain inulin on the quality of probiotic yogurt containing Lactobacillus rhamnosus. J Food Process Preserv 39: 1251-1260.

- Vital PA, Goto PA, Hanai LN, Gomes-da-Costa SM, de Abreu Filho BA, et al. (2015) Microbiological, functional and rheological properties of low fat yogurt supplemented with Pleurotus ostreatus aqueous extract. LWT - Food Sci Technol 64: 1028-1035.

- Illupapalayam VV, Smith SC, Gamlath S (2014) Consumer acceptability and antioxidant potential of probiotic-yogurt with spices. LWT - Food Sci Technol 55: 255-262.

- Guven M, Yasar K, Karaca OB, Hayaloglu AA (2005) The effect of inulin as a fat replacer on the quality of set-type low-fat yoghurt manufacture. Int J Dairy Technol 58: 180-184.

- Tamime AY, Deeth HC (1980) Yogurt technology and biochemistry. J Food Prot 43: 939-977.

- Biliaderis CG, Khan MM, Blank G (1992) Rheological and sensory properties of yogurt from skim milk and ultrafiltered retentates. Int Dairy J 2: 311-323.

- Akin MB, Akin MS, Kirmaci Z (2007) Effects of inulin and sugar levels on the viability of yogurt and probiotic bacteria and the physical and sensory characteristics in probiotic ice-cream. Food Chem 104: 93-99.

- Modzelewska-Kapitula M, Klebukowska L (2009) Investigation of the potential for using inulin HPX as a fat replacer in yoghurt production. Int J Dairy Technol 62: 209-214.

- Isik U, Boyacioglu D, Capanoglu E, Erdil DN (2011) Frozen yoghurt with added inulin and isomalt. J Dairy Sci 94: 1647-1656.

- Hanif MS, Zahoor T, Iqbal Z, Ihsan-ul-Haq Arif AM (2012) Effect of storage on rheological and sensory characteristics of cow and buffalo milk yogurt. Pak J Food Sci 22: 61-70.

- Supavititpatana P, Wirjantoro TI, Raviyan P (2010) Characteristics and shelf-life of corn milk yogurt. CMU J Nat Sci 9: 133-149.

- Izadi Z, Nasirpour A, Garoosi GA, Tamjidi F (2015) Rheological and physical properties of yogurt enriched with phytosterol during storage. J Food Sci Technol 52: 5341-5346.

- Sahan N, Yasar K, Hayaloglu AA (2008) Physical, chemical and flavor quality of non-fat yogurt as affected by a β-glucan hydrocolloidal composite during storage. Food Hydrocoll 22: 1291-1297.

- Schmitt C, Turgeon SL (2011) Protein/polysaccharide complexes and coacervates in food systems. Adv Colloid Interface Sci 167: 63-70.

- de Kruif CG, Weinbreck F, de Vries R (2004) Complex coacervation of proteins and anionic polysaccharide. Curr Opin Colloid Interface Sci 9: 340-349.

- Atamian S, Olabi A, Baghdadi OK, Toufeili I (2014) The characterization of the physicochemical and sensory properties of full-fat, reduced-fat and low-fat bovine, caprine, and ovine Greek yogurt (Labneh). Food Sci Nutr 2: 164-173.

- Ayar A, Gurlin E (2014) Production and sensory, textural, physicochemical properties of flavored spreadable yogurt. Life Sci J 11: 58-65.

- Tavakolipour H, Vahid-moghadam F, Jamdar F (2014) Textural and sensory properties of low-fat concentrated flavored yogurt by using modified waxy corn starch and gelatin as a fat replacer. Int J Biosciences 5: 61-67.

- Benbettaieb N, Gay JP, Karbowiak T, Debeaufort F (2016) Tuning the functional properties of polysaccharide-protein bio-based edible films by chemical, enzymatic, and physical cross-linking. Compr Rev Food Sci Food Saf 15: 739-752.

- Dickinson E (2008) Interfacial structure and stability of food emulsions as affected by protein-polysaccharide interactions. Soft Matter 4: 932-942.

- Nagae M, Yamaguchi Y (2014) Three-dimensional structural aspects of protein-polysaccharide interactions. Int J Mol Sci 15: 3768-3783.

- Semenova M G, Belyakova LE , Polikarpov YN, Antipova AS, Dickinson E (2009) Light scattering study of sodium caseinate+dextran sulfate in aqueous: Relationship to emulsion stability. In: Burlakova EB, Zaikov GE (Eds). Brill Leiden pp. 350.

- Semenova MG, Dickinson E (2010) Biopolymers in food colloids: Thermodynamics solution: Relationship to emulsion stability. Food Hydrocoll 23: 629-639.

- Ghosh AK, Bandyopadhyay P (2011) Simple strategy for charge selective biopolymer sensing. Chem Commun 47: 8937-8939.

- Turgeon SL, Schmitt C, Sanchez C (2007) Protein-polysaccharide complexes and coacervates. Curr Opin Colloid Interface Sci 12: 166-178.

- Dickinson E (2011) Mixed biopolymers at interfaces: Competitive adsorption and multilayer structures. Food Hydrocoll 25: 1966-1983.

- Grinberg VYa, Tolstoguzov VB (1997) Thermodynamic incompatibility of proteins and polysaccharides in solutions. Food Hydrocoll 11: 145-158..

- Abou-Soliman NH, Sakr SS, Awad S (2017) Physico-chemical, microstructural and rheological properties of camel-milk yogurt as enhanced by microbial transglutaminase. J Food Sci Technol 54: 1616-1627.

- Lee NK, Mok BR, Jeewanthi RK, Yoon YC, Paik HD (2015) Physicochemical and microbiological properties of yogurt-cheese manufactured with ultrafiltrated cow's milk and soy milk blends. Korean J Food Sci Anim Resour 35: 205-210.

- Fagan CC, O’Donnell CP, Cullen PJ, Brennen CS (2006) The effect of dietary fiber inclusion on milk coagulation kinetics. J Food Eng 77: 261-268.

- de Souza Oliveira RP, Perego P, de Oliveira MN, Converti A (2011) Effect of inulin as prebiotic and synbiotic interactions between probiotics to improve fermented milk firmness. J Food Eng 107: 36-40.

- Montanuci FD, Pimentel TC, Garcia S, Prudencio SH (2012) Effect of starter culture and inulin addition on microbial viability, texture, and chemical characteristics of whole or skim milk kefir. Cienc Tecnol Aliment 32: 850-861.

- Ozer BH, Kirmaci HA (2010) Functional milks and dairy beverages. Int J Dairy Technol 63: 1-15.

- Zacarchenco PB, Massaguer-Roig S (2006) Properties of Streptococcus thermophilus fermented milk containing variable concentrations of Bifidobacterium longum and Lactobacillus acidophilus. Braz J Microbiol 37: 338-344.

- Katsiari MC, Voutsinas LP, Kondyli E (2002) Manufacture of yogurt from stored frozen sheep’s milk. Food Chem 77: 413-420.